FEATURE

SPEEDIO’s Environmental Performance

To achieve carbon neutral

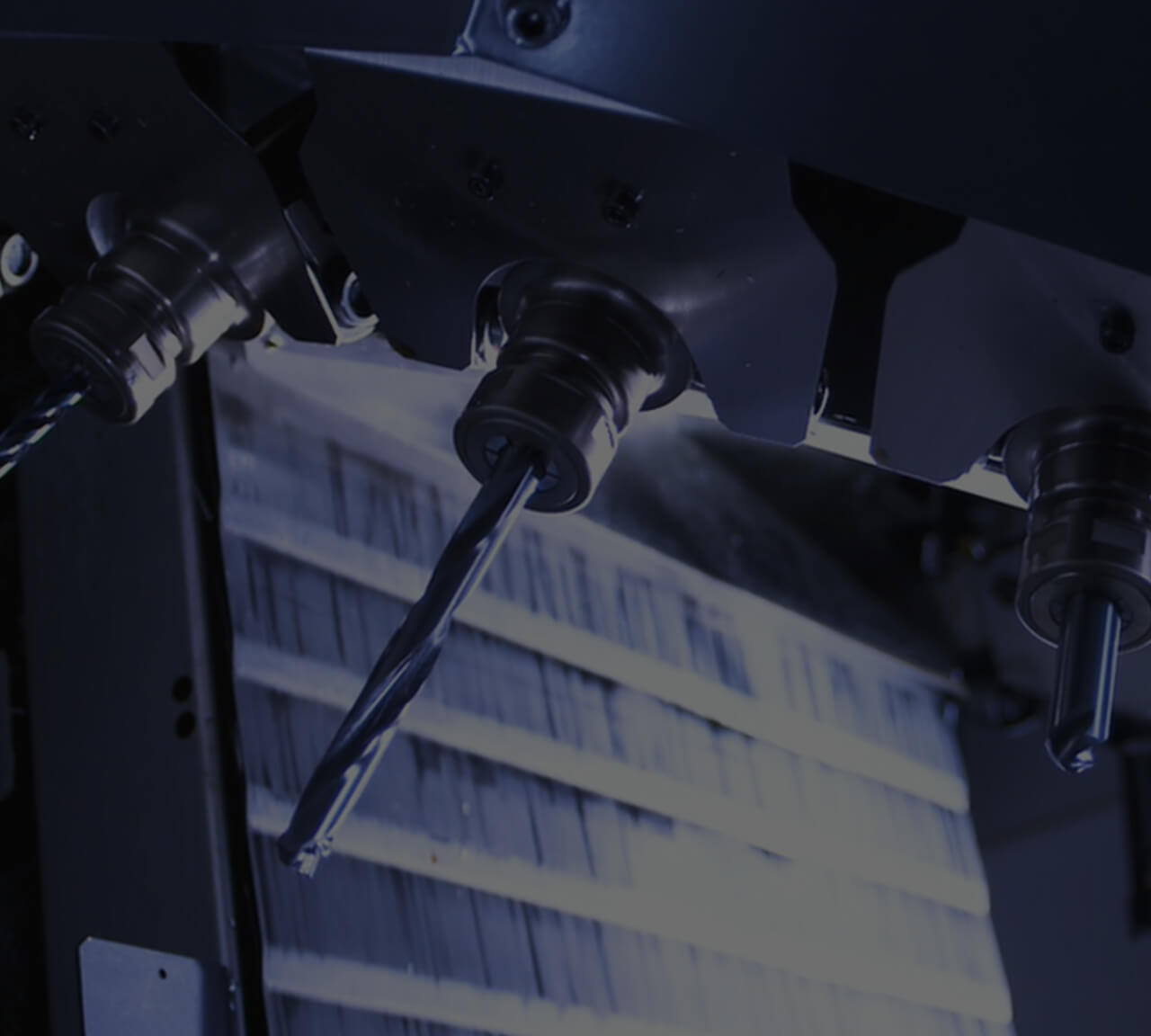

While retaining the #30 spindle, and based on Brother’s original technology, the SPEEDIO strives for industry-leading environmental performance, in addition to overwhelming high productivity, machining capabilities, and usability.

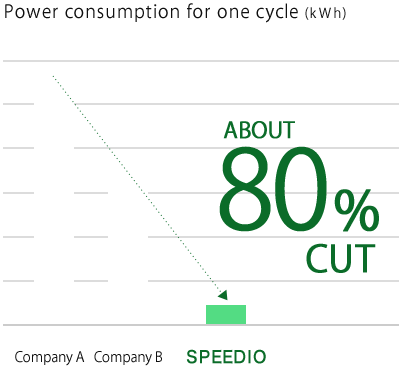

When machining is performed

by replacing a general #40

machining center with the SPEEDIO,

Power consumption reduced

by approx. 80%

The SPEEDIO has been developed with a focus on high speed and high efficiency. Compared to #40 machining centers, the SPEEDIO provides faster machining speed and superior energy efficiency.

Machining time can be shortened, contributing to reduction in power consumption per cycle. Shortening working hours can also contribute to reduction in power consumption for plantwide air conditioning, lighting etc.

* Data taken running machining program created by Brother

TECHNOLOGY

Technology to Achieve Energy Saving

Low power consumption

-

1.The SPEEDIO has achieved energy saving by combining the IPM motor with a power regeneration system.

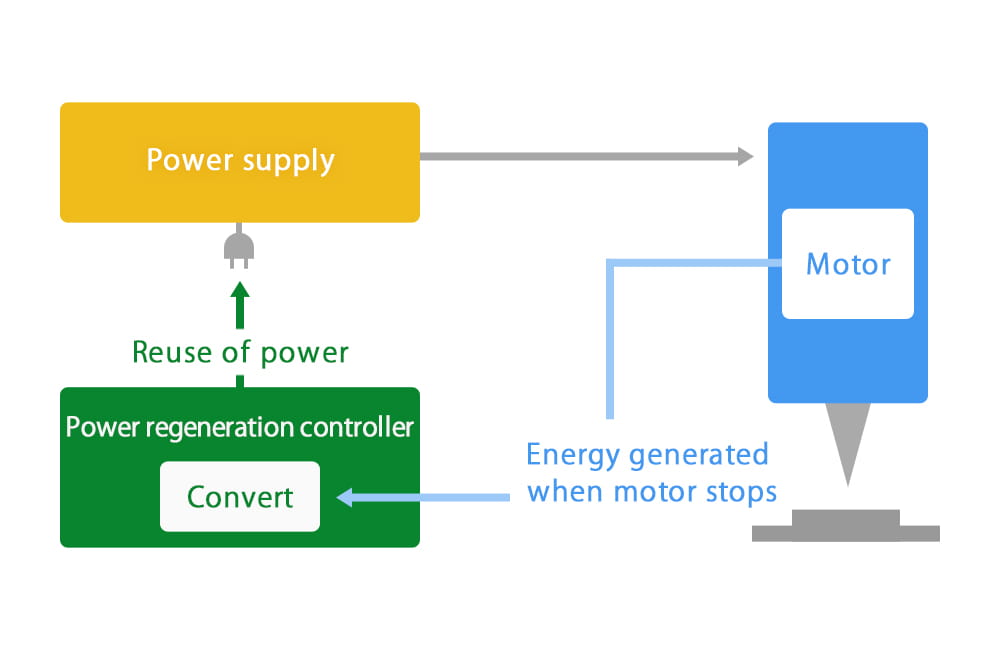

Power regeneration system

Equipped with a power regeneration system that reuses energy generated when the spindle motor decelerates.

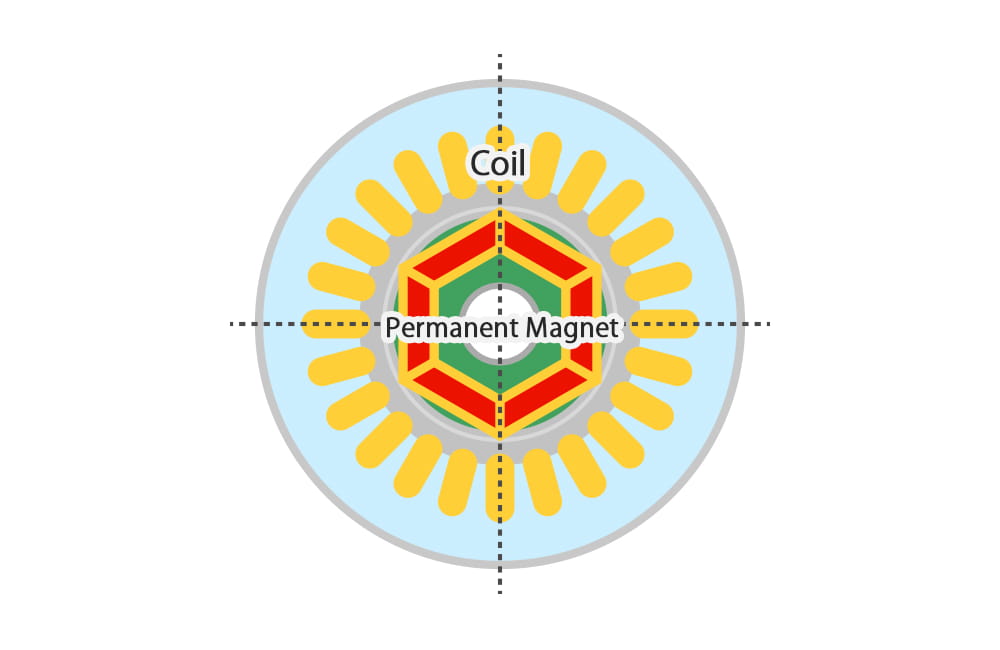

IPM motor is used for the spindle motor

As a permanent magnet is used in the rotor, there is no need to apply current to produce magnetic flux. This means that the IPM motor is more effective and can start quickly, compared to a general induction motor. In addition, this highly efficient motor with high torque in the medium- and high-speed range enables higher work efficiency and energy saving.

-

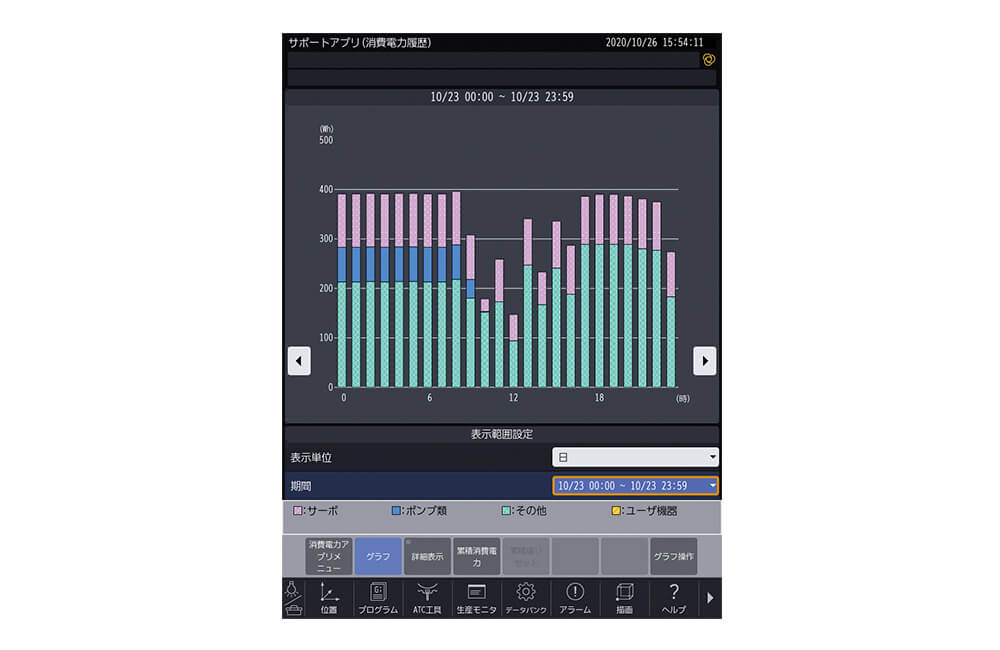

2.Low power consumption achieved by providing various energy saving functions.

Energy saving NC functions

Equipped with Automatic coolant off, Standby mode, Automatic work light off, Automatic power off, etc.

Energy saving pump

An impeller suitable for the usage conditions, including pressure and flowrate, is used to pump coolant effectively.

LED work light

LED lights with less power consumption than normal lights are optionally available, achieving extended service life and energy saving.

Low air consumption

Air consumption load have been reduced by eliminating all possible waste to

optimize functions. High environmental performance.

Compared to a general machining center, air consumption is reduced by approx. 80%.

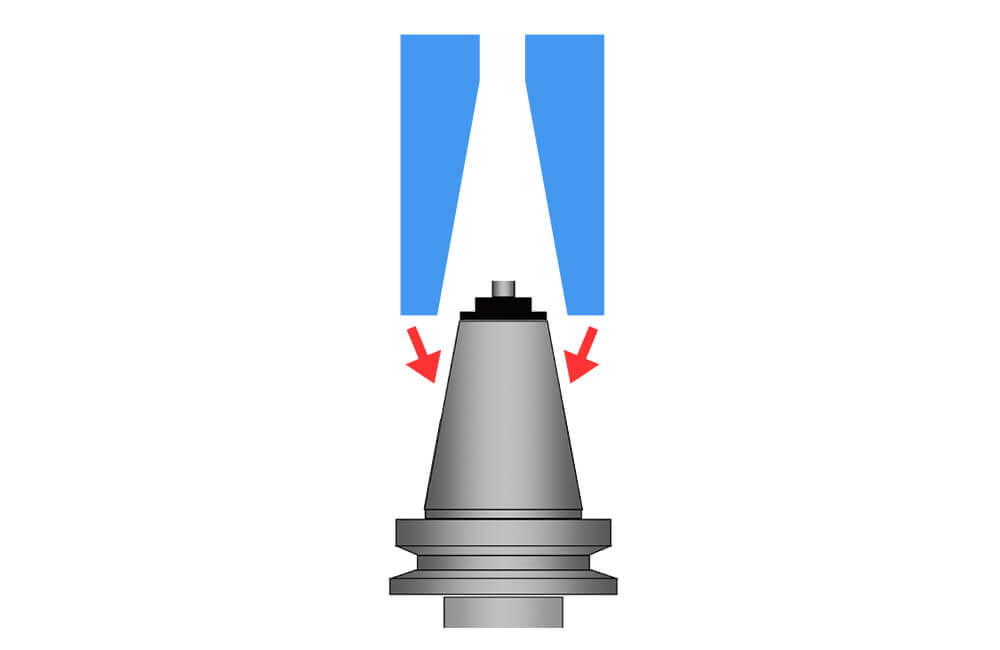

Air purge

After substantial flowrate analysis, a highly sealed structure that prevents the coolant penetrating the spindle even with less air purge has been achieved. Greatly reduces air consumption.

Spindle air blow

While reducing air consumption by half, three times the conventional volume of air is discharged only when required to enhance cleaning power. Compared to the case of using only a pump, cleaning is possible with less power consumption.

SPEEDIO is a brand of #30 machine for customers who demand high productivity, which has high machining ability while having compactness and speed not found in #40, and is eco-friendly.

READ MORE

-

Compact Machining Center

-

Compact Machining Center

-

Wide Travel

Compact

Machining Center

-

Pallet Changing

Compact Machining Center

-

Universal

Compact Machining Center -

High Rigidity

Compact Machining Center

-

Compact Multi-task Machine

-

Special options

-

T-200A/T-200Ad

- T-200A/T-200Ad

- Rotary Table High accuracy, High productivity. Maximum loading capacity (kg) 100 (When support table is used 200)

VIEW MORE -

BV7-870

-

BV7-870Ad

-