which has high machining ability while having compactness and speed not found in #40,

and is eco-friendly.

With a wide selection of products, we provide customers with optimal solutions

avoiding any waste in a variety of fields, including automobiles,

EVs, IT equipment, and medical equipment.

-

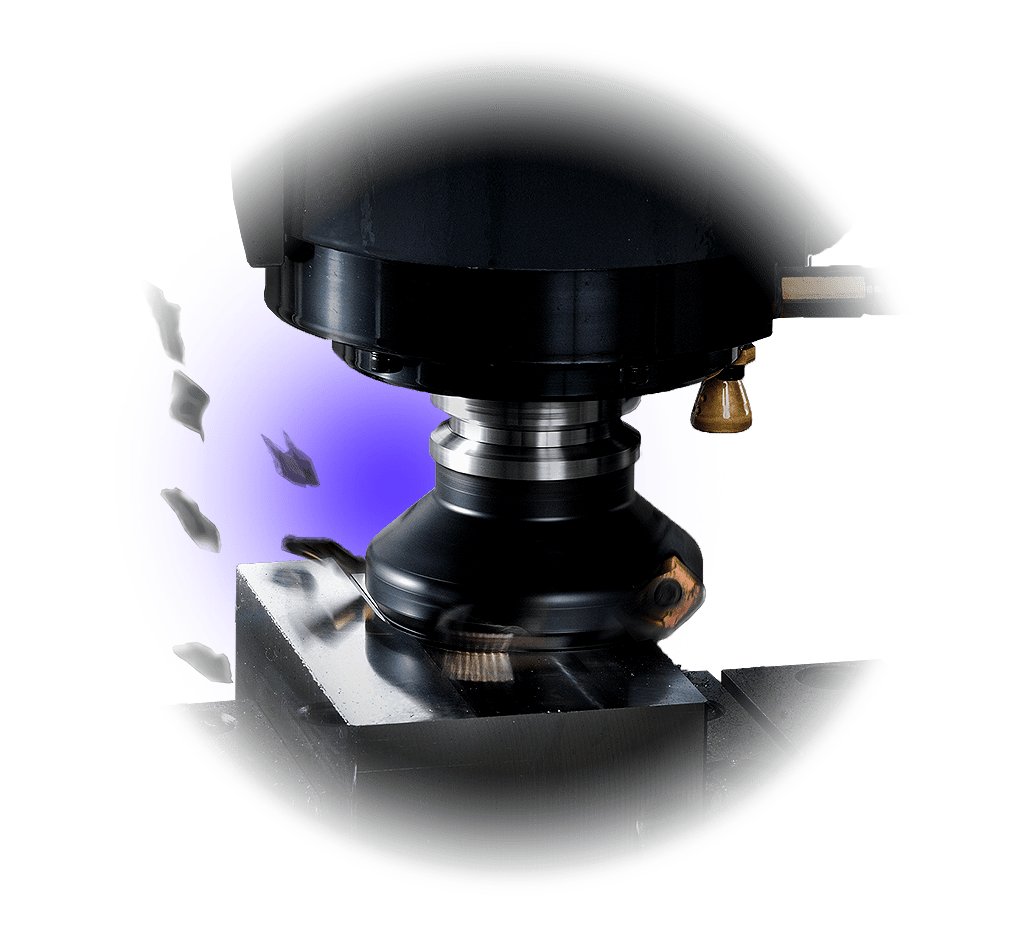

Overwhelming high productivity

High-speed operations and optimized control have been achieved by the #30 spindle taper and machine/controller integrated development (original NC), enabling the machine to demonstrate high productivity.

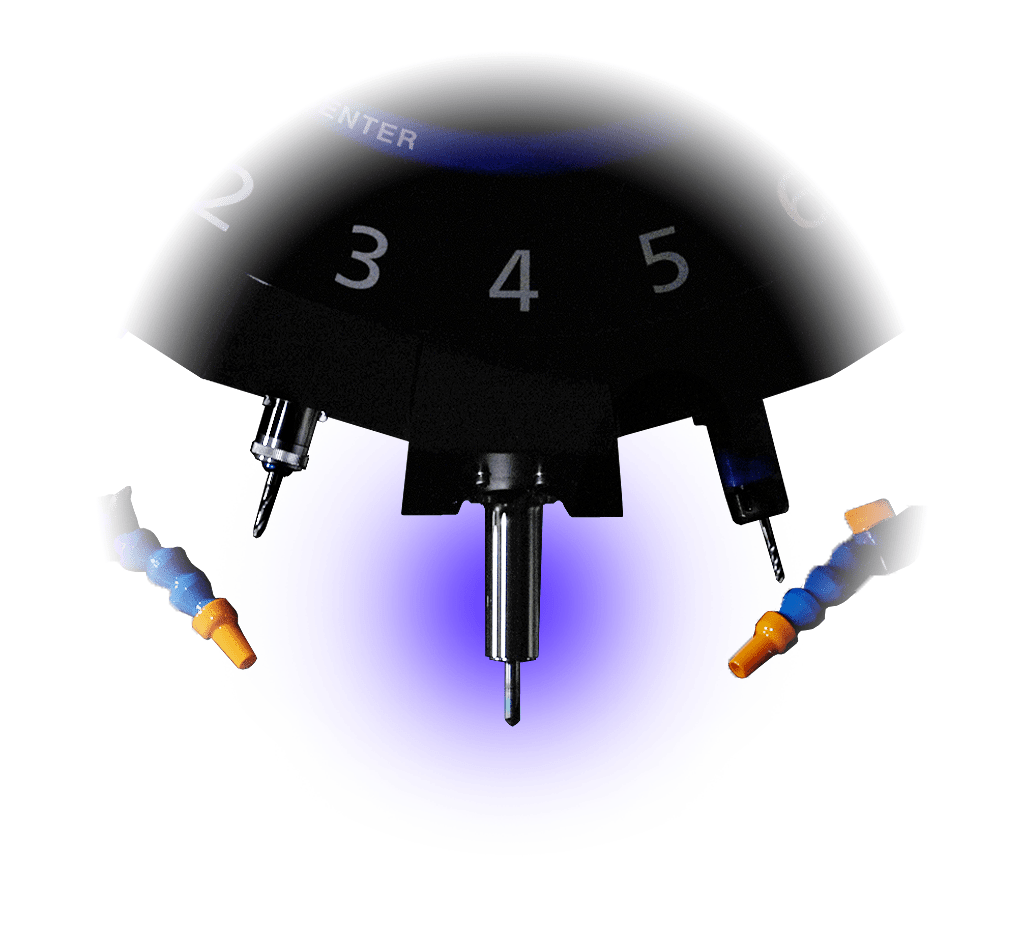

Nonstop ATC

Tool change time has been reduced by increasing

the speed of spindle start/stop,

Z-axis up/down, and magazine operation.Simultaneous operation control

Reduction in non-cutting time has been achieved

by simultaneously performing tool change

and positioning X/Y and additional axes. -

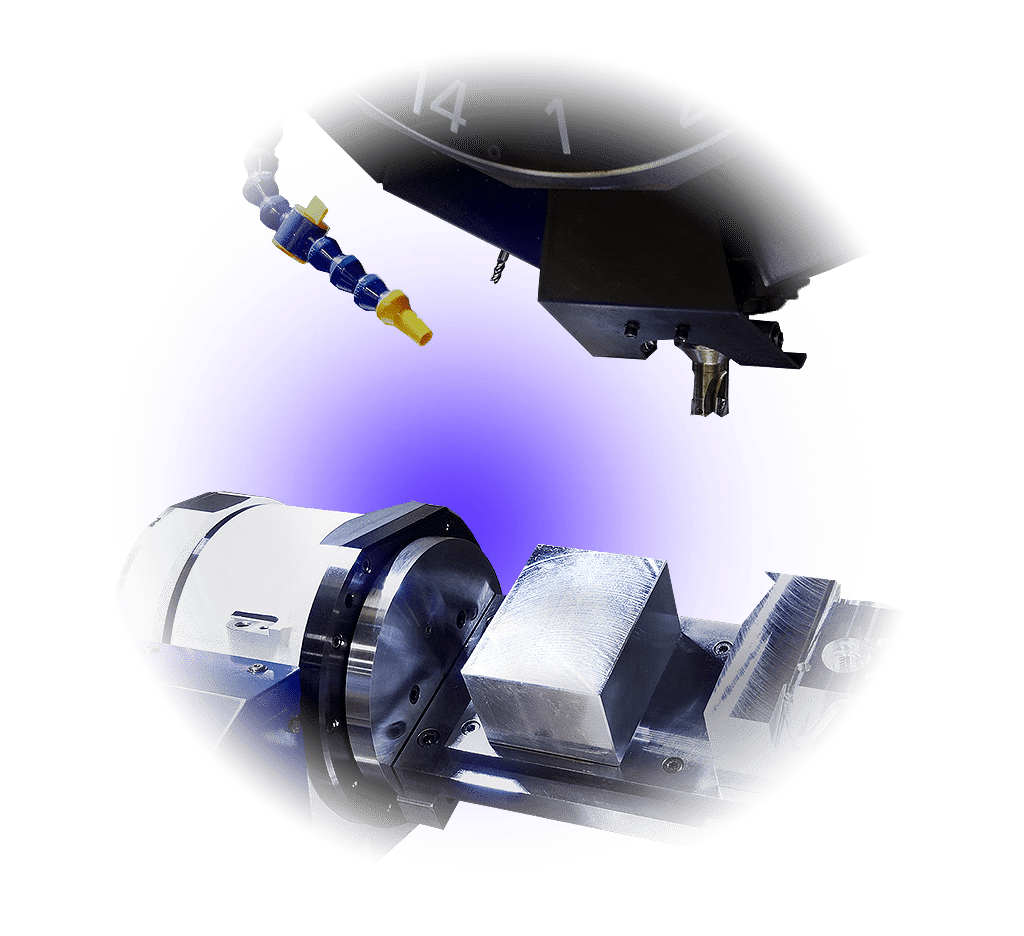

High Machining capabilities

The highly rigid structure and highly efficient spindle motor allow the machine to demonstrate its broad machining capabilities, from high-efficiency machining to heavy-duty machining.

Highly rigid structure

Accumulating analysis and technical data throughout

the machine design phase has achieved high rigidity.Highly efficient spindle motor

The SPEEDIO focuses on the spindle motor to

demonstrate high torque over a broad range

from low speed to high speed. -

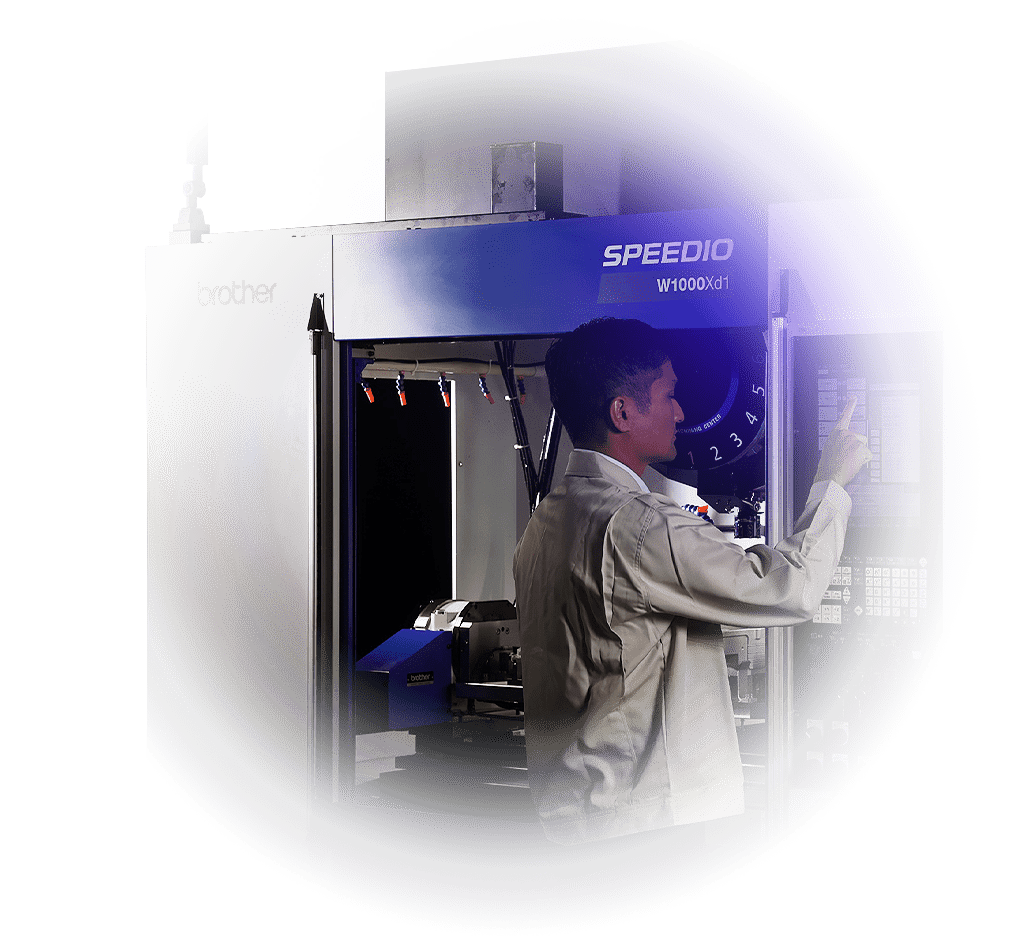

Highly Usability

Original NC achieves waste-free operation optimized for manufacturing, and improves work efficiency and operating rate at production sites.

New "CNC-D00" controller

Intuitive operation is possible with 15-inch

vertical touch panel screen and new support app.Supports Setup, Adjustment,

Productivity, RecoveryRelevant functions are grouped according to

purpose, such as setup and machining,

leading to efficient operation.

Production and operation states are visualized,

allowing faster undergrounding.

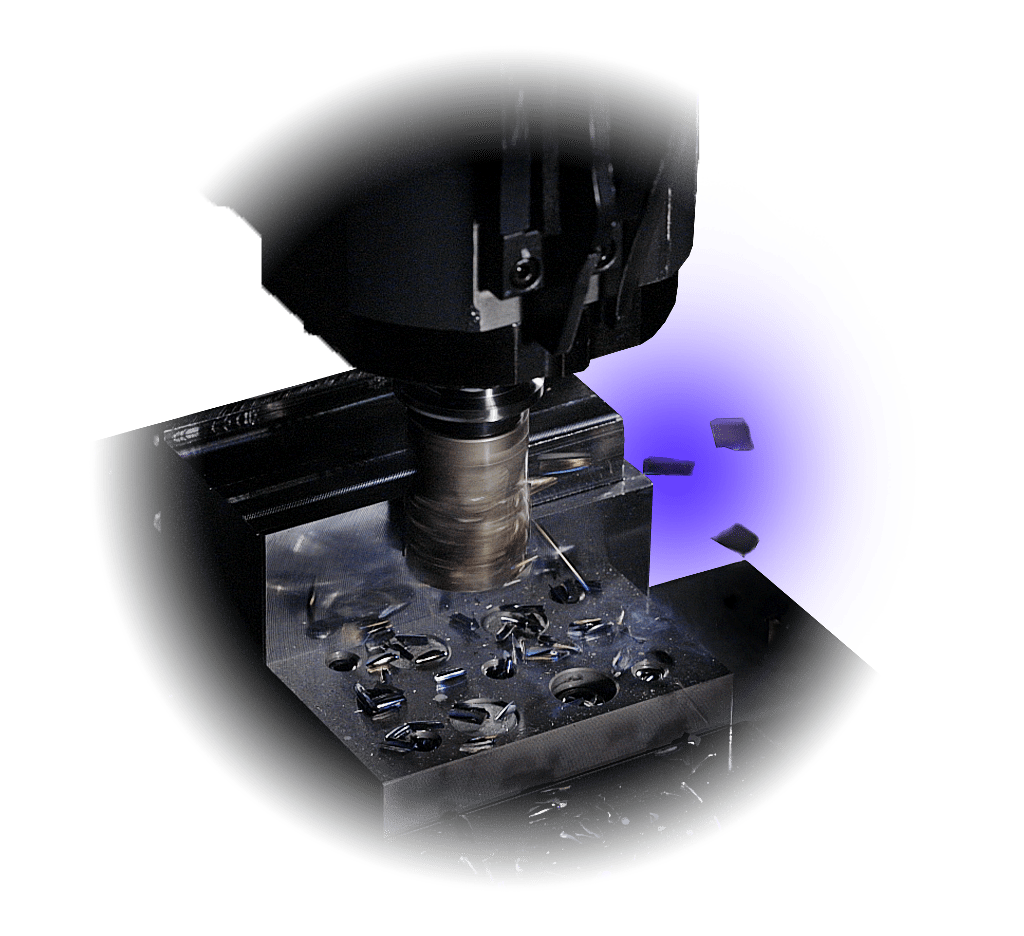

SPEEDIO

Blue Technology

Solves Four Waste Elements at Production Sites

Blue Technology

Eliminating waste elements at production sites leads to reduction in greenhouse gas emissions, such as carbon dioxide and methane. Brother’s optimal and compact design reduces wasted time, resources, and energy during parts machining.

READ MORE