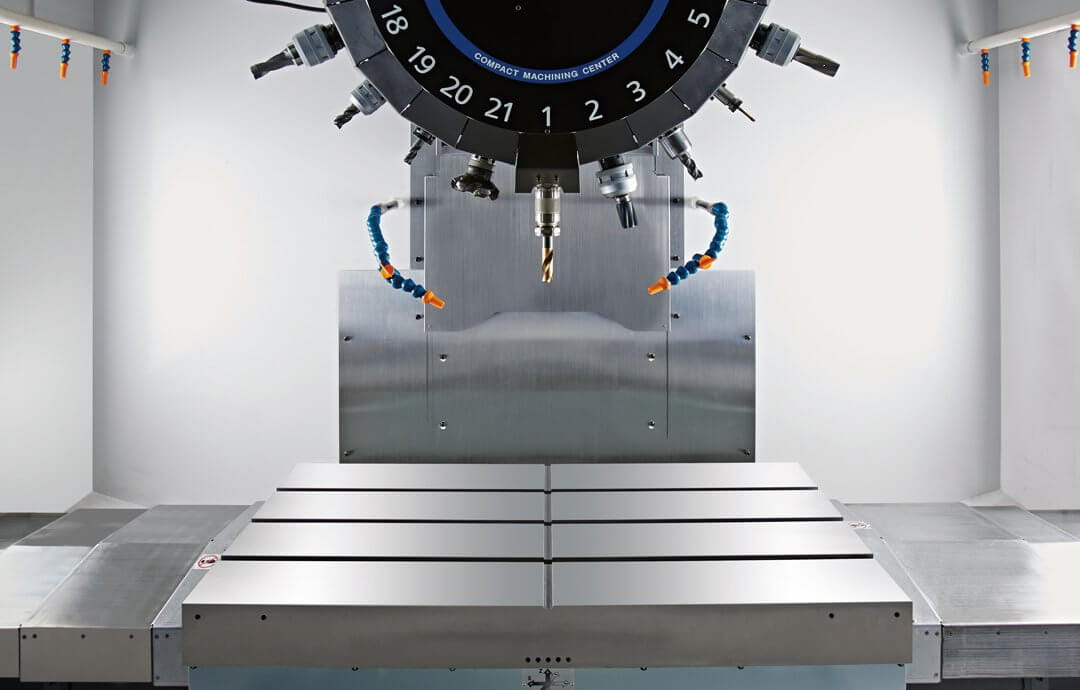

SPEEDIO S1000X1

Compact Machining Center

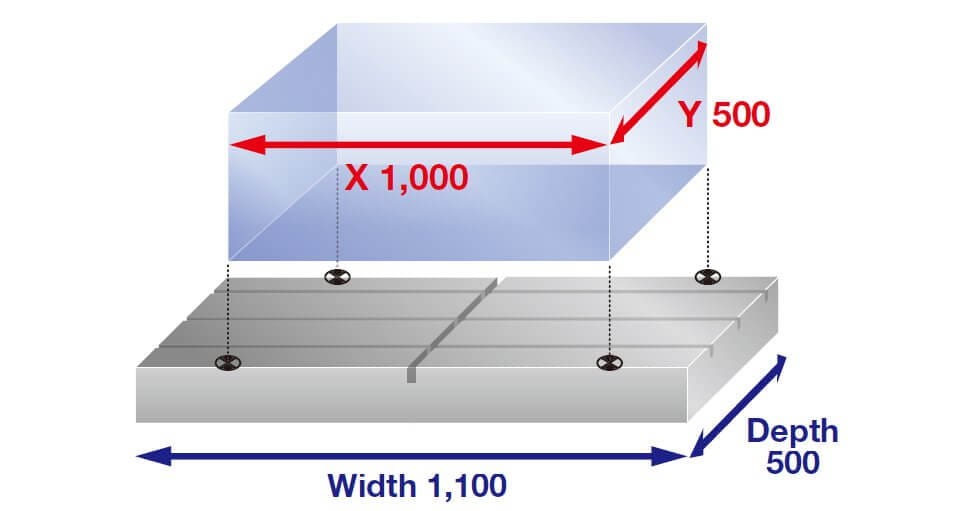

- Travels (mm): X: 1,000 Y: 500 Z: 300

- Max. spindle speed (min-1): 10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

- Tool storage capacity(pcs.): 14/ 21

"Machining larger workpieces using #30 machine" The release of the S1000X1 machining center sees an override in the conventional machining areas of #30 machines. Continuing in the spirit of overwhelming high productivity, the machine will launch a challenge to new machining areas, boosting our "Brother also in this process" concept.

Information

Overview

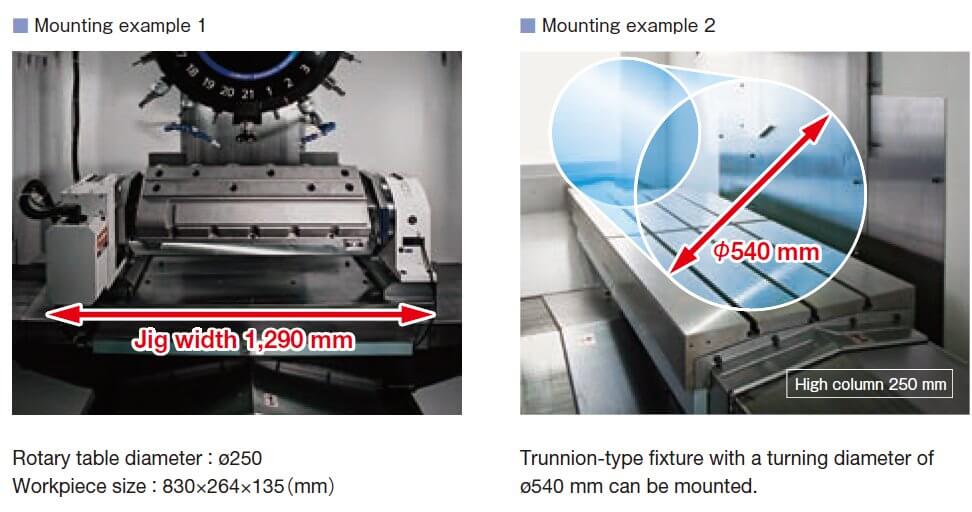

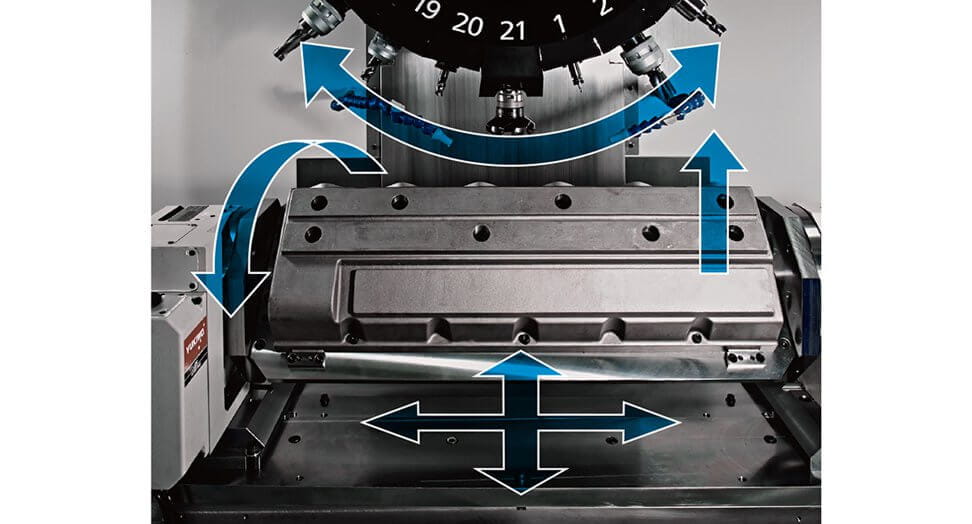

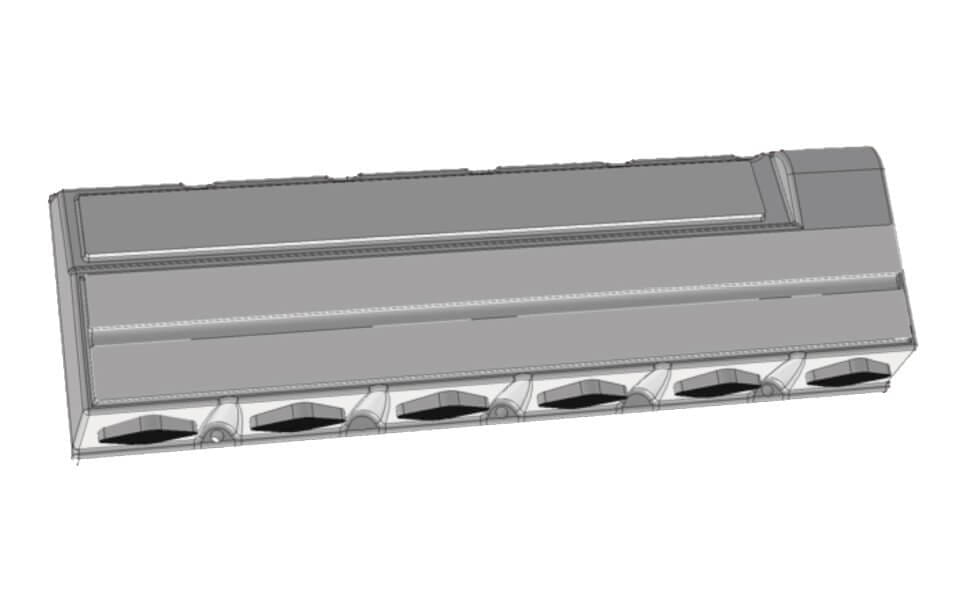

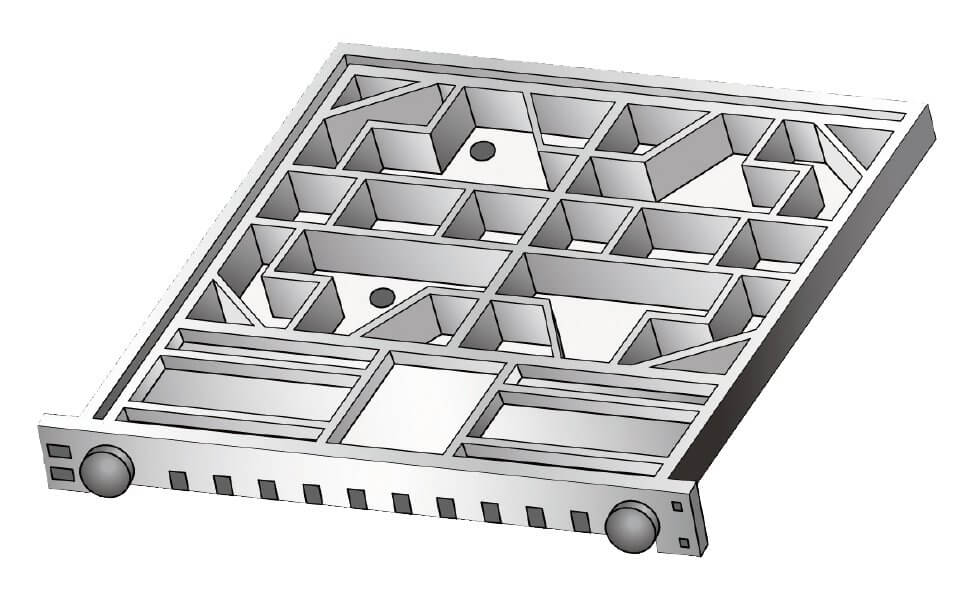

Increase in X- and Y-axes travels and expansion of the machining area have enabled large workpiece machining and large jig mounting, which were not possible on conventional #30 machines.

Wasted time has been further reduced by simultaneously performing tool change and positioning X/Y and additional axes.

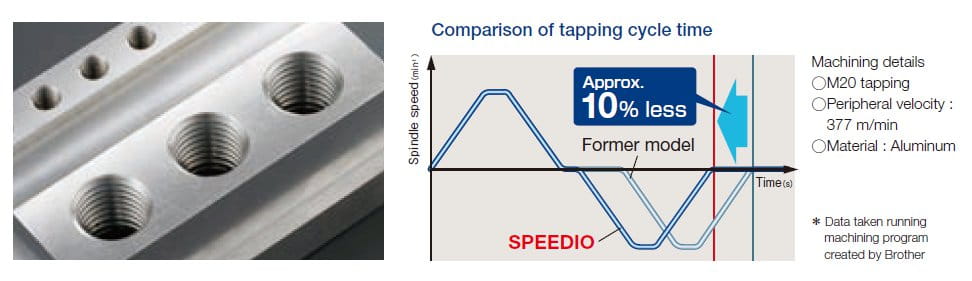

Using a fast acceleration/deceleration spindle motor enables the spindle to start and stop in an extremely short time.

Spindle start/stop time

0.15s

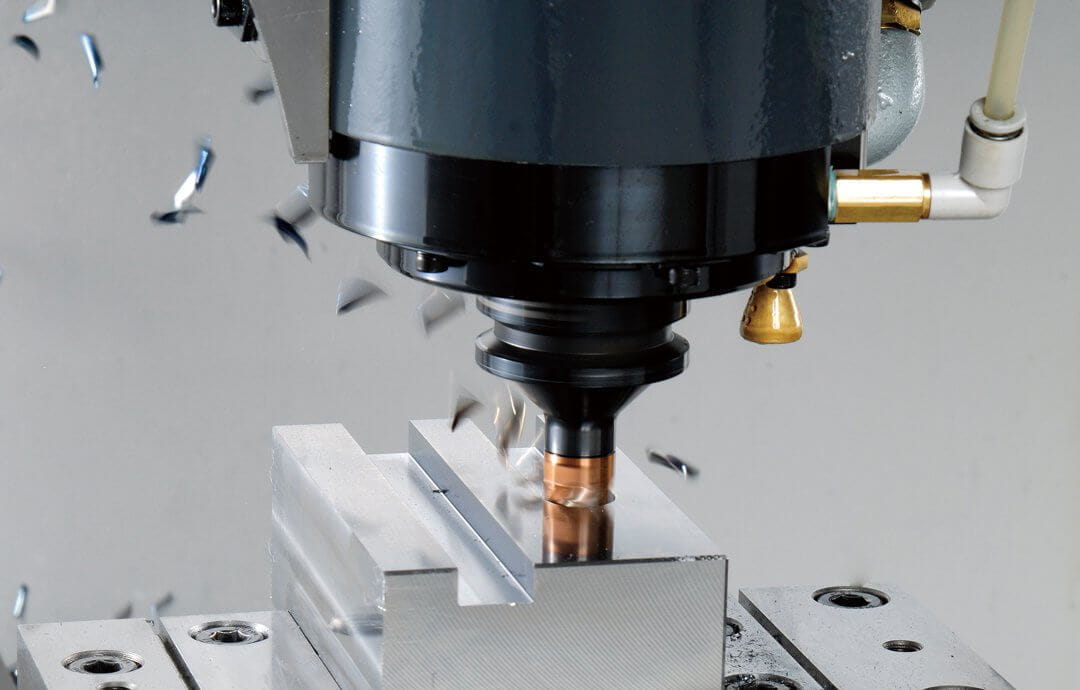

High-speed tool change has been achieved by optimizing and increasing the speed of spindle start/stop, Z-axis up/down, and magazine movement.

Chip - Chip : 1.4s

Tool - Tool : 0.8s

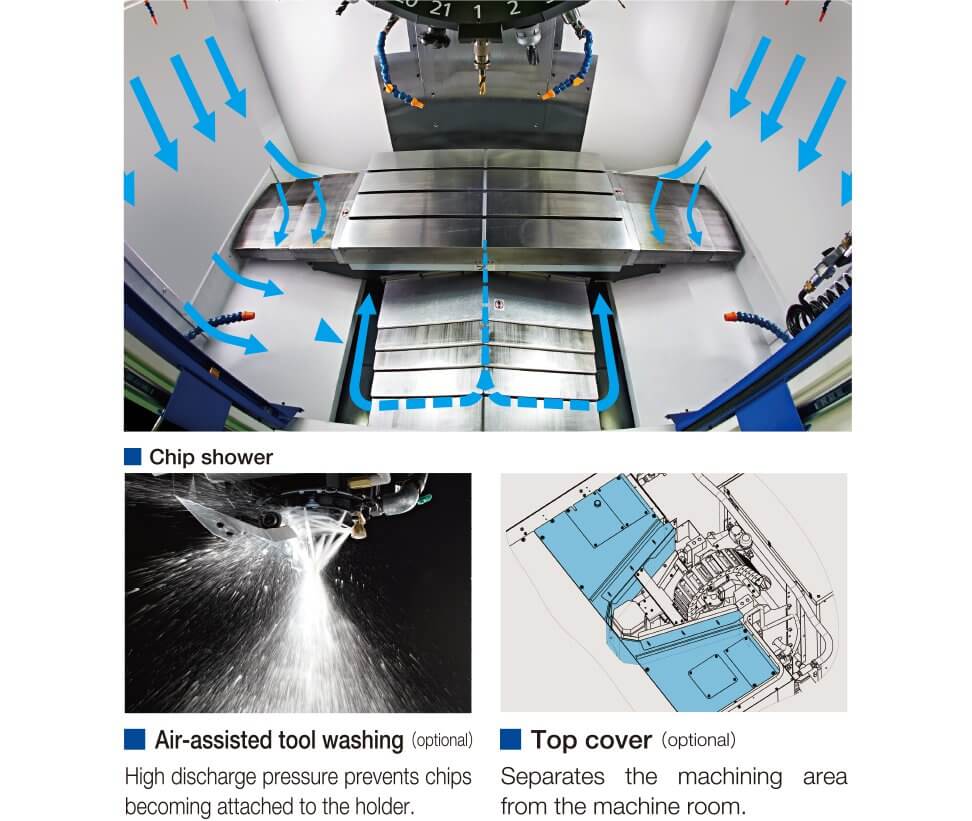

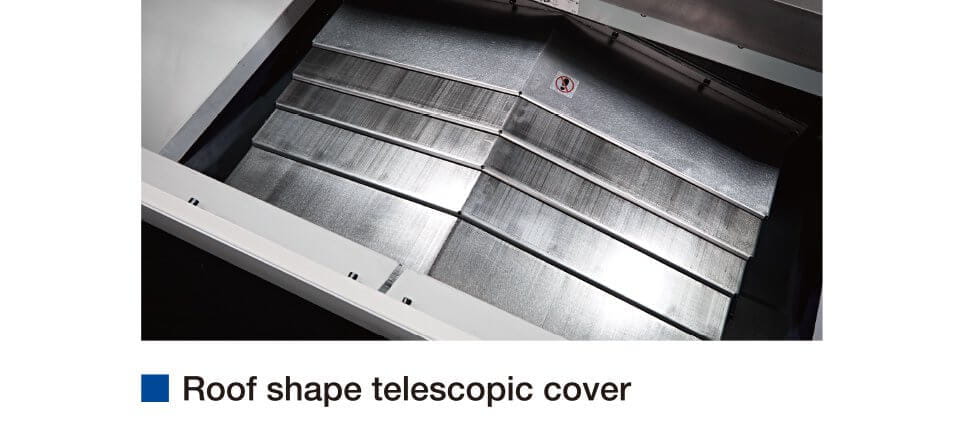

Chip discharge performance has been improved along with the expansion of the machining area. In addition, the machine is equipped with a variety of functions, such as air-assisted tool washing, to improve reliability.

Specifications

Product Specification

S1000X1

Max. spindle speed [min⁻¹]

10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

Travels [mm (inch)]

X: 1,000 Y: 500 Z: 300

Tool storage capacity [pcs.]

14/ 21

Rapid traverse rate (XYZ axes) [m/min (inch/min)]

50 x 50 x 50

Required floor space [mm (inch)]

2,410 x 2,442

BT dual contact spindle(BIG-PLUS)

Optional

Coolant Through Spindle(CTS)

Optional

| item | S1000X1 | ||

|---|---|---|---|

| CNC unit | CNC-C00 | ||

| Travels | X axis [mm (inch)] | 1,000 (39.4) | |

| Y axis [mm (inch)] | 500 (19.7) | ||

| Z axis [mm (inch)] | 300 (11.8) | ||

| Distance between table top and spindle nose end [mm (inch)] | 180~480 (7.1~18.9) | ||

| Table | Work area size [mm (inch)] | 1,100 x 500 (43.3 x 19.7) | |

| Max.loading capacity (uniform load) [kg (lbs)] | 300[400] (661.3[881.8])*1 | ||

| Spindle | Spindle speed [min-1] | 10,000min-1 specifications : 10 - 10,000 10,000min-1 high-torque specifications(Optional) : 10 - 10,000 16,000min-1 specifications(Optional) : 16 - 16,000 |

|

| Speed during tapping [min-1] | MAX. 6,000 | ||

| Tapered hole | 7/24 tapered No.30 | ||

| BT dual contact system (BIG-PLUS) | Optional | ||

| Coolant Through Spindle (CTS) | Optional | ||

| Feed rate | Rapid traverse rate (XYZ-area) [m/min (inch/min)] | 50 x 50 x 56 (1,969 x 1,969 x 2,205) | |

| Cutting feed rate [mm/min (inch/min)] | X, Y, Z : 1 - 30,000 (0.04 - 1,181)*2 | ||

| ATC unit | Tool shank type | MAS-BT30 | |

| Pull stad type*3 | MAS-P30T-2 | ||

| Tool storage capacity [pcs.] | 14/21 | ||

| Max. tool length [mm (inch)] | 250 (9.8) | ||

| Max. tool diameter [mm (inch)] | 110 (4.3) | ||

| Max. tool weight [kg (lbs)]*4 | 3.0 (6.6) (Total tool weight : 25 (55.1) for 14 tools, 35 (77.2) for 21 tools) | ||

| Tool selection method | Random shortcut method | ||

| Tool change time*5 | Tool To Tool : 0.8sec. Chip To Chip : 1.4sec. Cut To Cut : 1.2sec. |

||

| Electric motor | Main spindle motor (10 min/continuous) [kW]*6 | 10,000min-1 specifications : 10.1/6.7 10,000min-1 high-torque specifications(Optional) : 12.8/8.8 16,000min-1 specifications(Optional) : 7.4/4.9 |

|

| Axis feed motor [kW] | X,Y : 1.0 Z : 2.0 | ||

| Power source | Power supply | AC 200V ±10%, 50/60Hz ±1Hz | |

| Power capacity (continuous) [kVA] | 10,000min-1 specifications : 9.5 10,000min-1 high-torque specifications(Optional) : 10.4 16,000min-1 specifications(Optional) : 9.5 |

||

| Air supply | Regular air pressure [MPa] | 0.4 - 0.6 (recommended value : 0.5MPa)*7 | |

| Required flow [L/min] | 45 | ||

| Machine dimensions | Height [mm (inch)] | 2,532 (99.7) | |

| Required floor space (with control unit door open) [mm (inch)] | 2,410 x 2,442[2,967] (94.9 x 96.1[116.8]) | ||

| Weight (including control unit, machine cover) [kg (lbs)] | 3,300 (7,275) | ||

| Accuracy*8 | Accuracy of bidirectional axis positioning (ISO230-2:2006) [mm (inch)] | 0.006 - 0.020 (0.00024 - 0.00079) | |

| Repeatability of bidirectional axis positioning (ISO230-2:2006) [mm (inch)] | Less than 0.004 (0.00016) | ||

| Standard accessories | Instruction Manual (1 set), anchor bolts (4 pcs.), leveling bolts (4 pcs.), machine cover (manual door) | ||

- *1 Acceleration must be adjusted for X and Y axes.

- *2 When using high accuracy mode B.

- *3 Brother specifications apply to the pull studs for CTS.

- *4 Actual tool weight differs depending on the configuration and center of gravity. The figures shown here are for reference only.

- *5 Measured in compliance with JIS B6336-9 and MAS011-1987.

- *6 Spindle motor output differs depending on the spindle speed.

- *7 Regular air pressure varies depending on the machine specifications, machining program details, or use of peripheral equipment. Set the pressure higher than the recommended value.

- *8 Measured in compliance with ISO standards and Brother standards.

| CNC model | CNC-C00 | |

|---|---|---|

| Control axes | 5axes ( X, Y, Z, additional axes) | |

| Simultaneously controlled axes | Positioning | 5 axes (X, Y, Z, A, B) |

| Interpolation |

|

|

| Least input increment | 0.001 mm, 0.0001 inch, 0.001 deg. | |

| Max.programmable dimension | 9999.999mm, 999.9999inch | |

| Display | 12.1-inch color LCD | |

| Memory capacity | Approx.100 Mbytes (Total capacity of program and data bank) | |

| External communication | USB memory interface, Ethernet, RS232C 1ch | |

| No.of registrable programs | 4,000 (Total capacity of program and data bank) | |

| Program format | NC language, conversation (changed by parameter), conversion from conversation program to NC language program available |

|

| Standard NC functions |

|

|

| Optional NC functions |

|

|

- *1 Measuring instrument needs to be prepared by users.

- *2 When the submicron command is used, changing to the conversation program is disabled.

- * When program size is bigger than 2 Mbytes. machine works with extended memory operation.

- * Ethernet is a trademark or registered trademark of XEROX in the United States.

- * Functions listed under (NC) and (Conversation) are available only for NC programs and conversation programs respectively.

For options, please contact us.

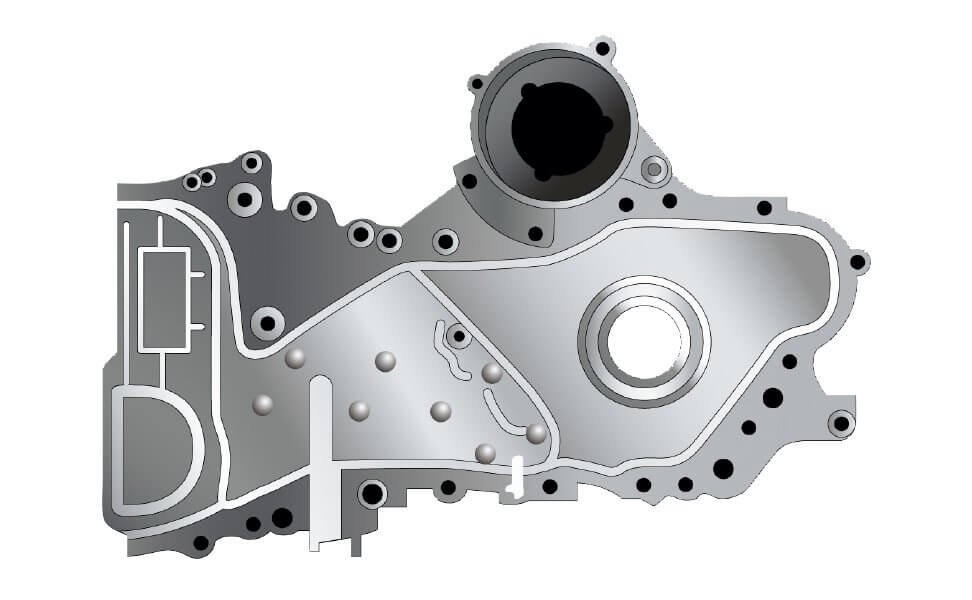

Example

ADC

ADC

ADC