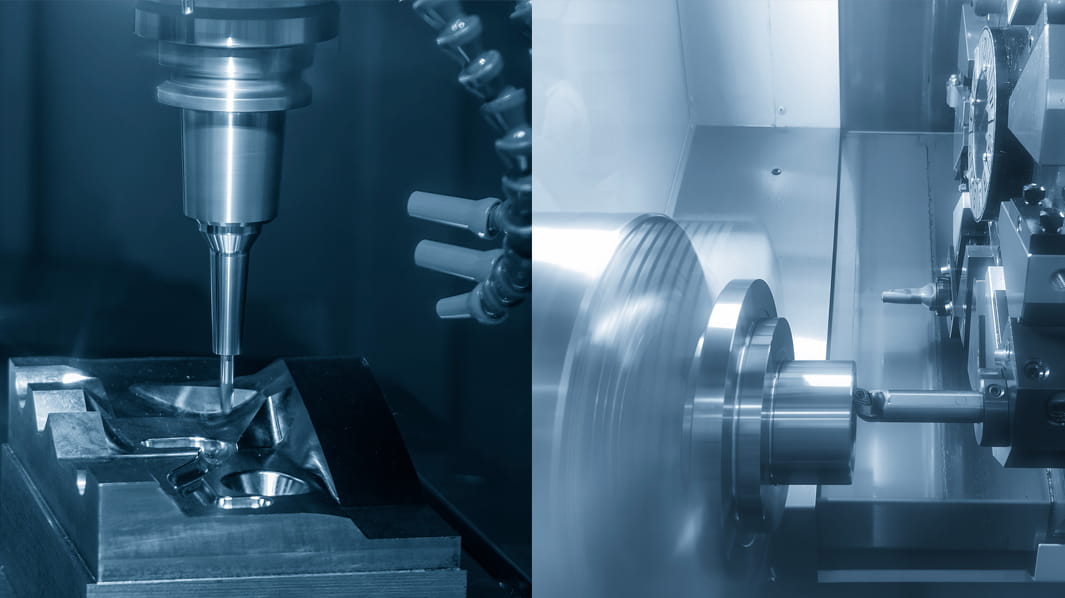

What Is a Machining Center? The Basics on Structure, Types, Benefits, etc.

The machining center is a type of machine tool used to manufacture various parts. Equipped with an automatic tool changer (ATC), it can be used to automate machining of multiple workpieces, such as milling, drilling, and boring, making it an indispensable presence in manufacturing sites. This article will introduce the features and benefits of machining centers for those who want to learn more about machining centers or are considering introducing new machine tools.

NC is an acronym for numerical control. As the name suggests, this is the heart of a machining center, responsible for precisely controlling machine tool movements and tool operation based on programmed numerical data. The NC unit makes it possible to produce parts of complex geometry and perform precision machining.

The NC control panel is the interface for operating the NC unit. The NC control panel has various buttons and switches with a display for the operator to enter various instructions.

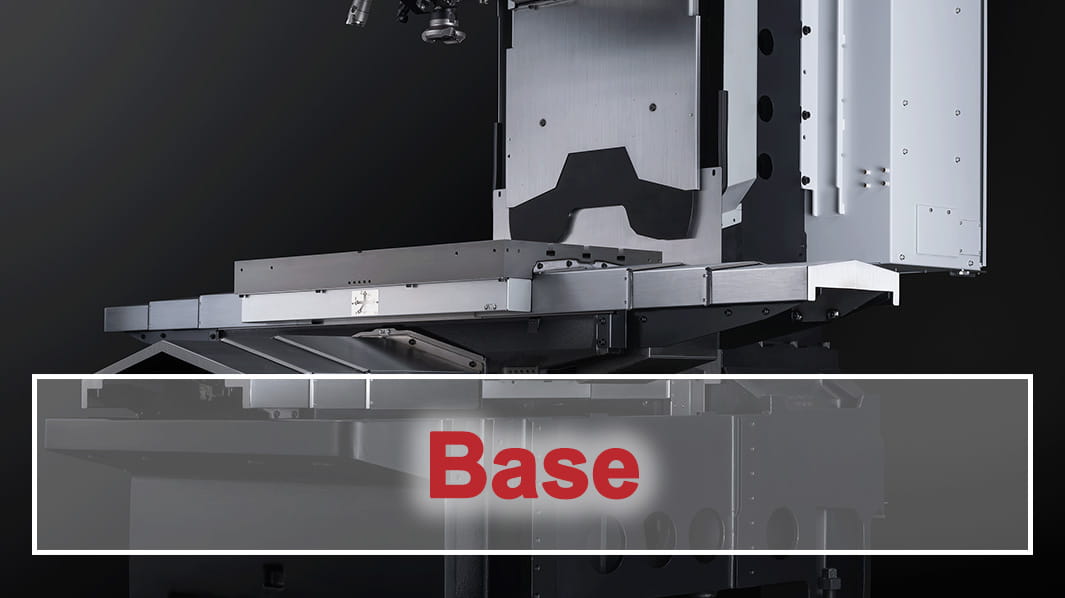

As the name suggests, this is the base of the machine, where the bottom of the machine touches the floor. The base is generally made of a sturdy material to ensure overall stability and accuracy. Depending on the manufacturer and machine type, the base may be called a bed.

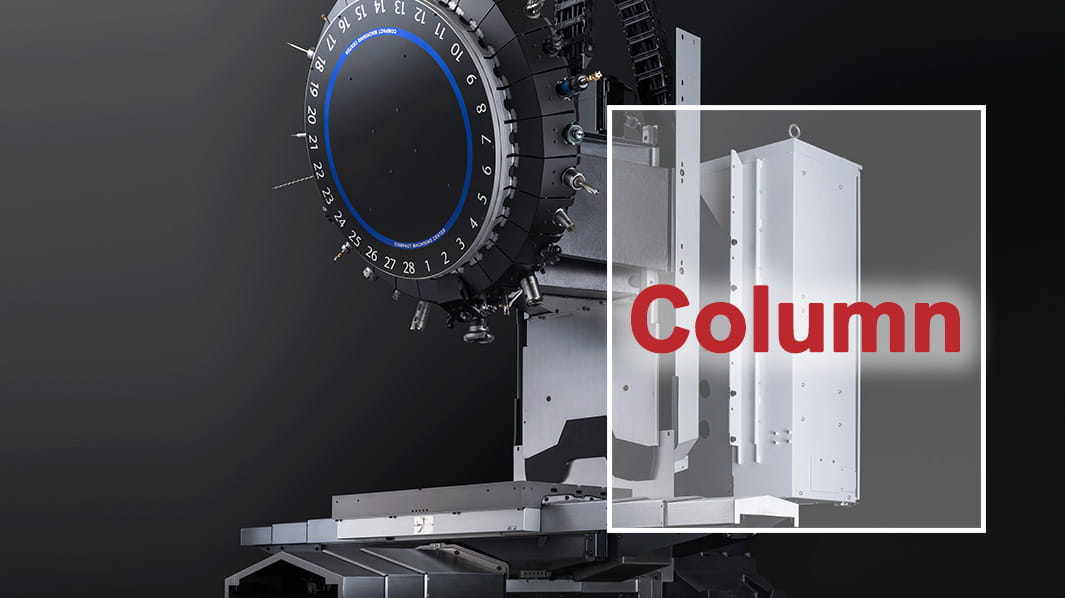

Column refers to the vertical frame of the machining center. In contrast to the base, the column acts like the spine of the machine, extending towards the top.

The spindle is where the cutting tool is mounted, and spindle speed and stability greatly affects the machining quality. Tooling refers to an adapter that connects the spindle and tool. Like tools, toolings come in various shapes, and they consist of a tool holder and shank. Note that machining centers are categorized as either BT30 or BT40 according to the shank size.

Cutting tools are tools used in machining centers, with primary examples being end mills, milling cutters, and drills. Tools are selected according to the machining details and the material to be machined, and if used appropriately, they make high accuracy machining possible.

Milling cutter: A generic term for tools commonly used in milling machines. Milling cutters are used for a wide range of applications from roughing to finishing and are divided into several categories, including flat milling cutters and side milling cutters.

End mill: A tool with blades called flutes extending from its tip out to its circumference. Classified as a milling tool, end mills are known as a universal tool for their ability to perform multiple machining operations, such as groove machining, side cutting, and tapering with a single tool.

Drills: Mainly used for drilling and come in various shapes, diameters, and depths.

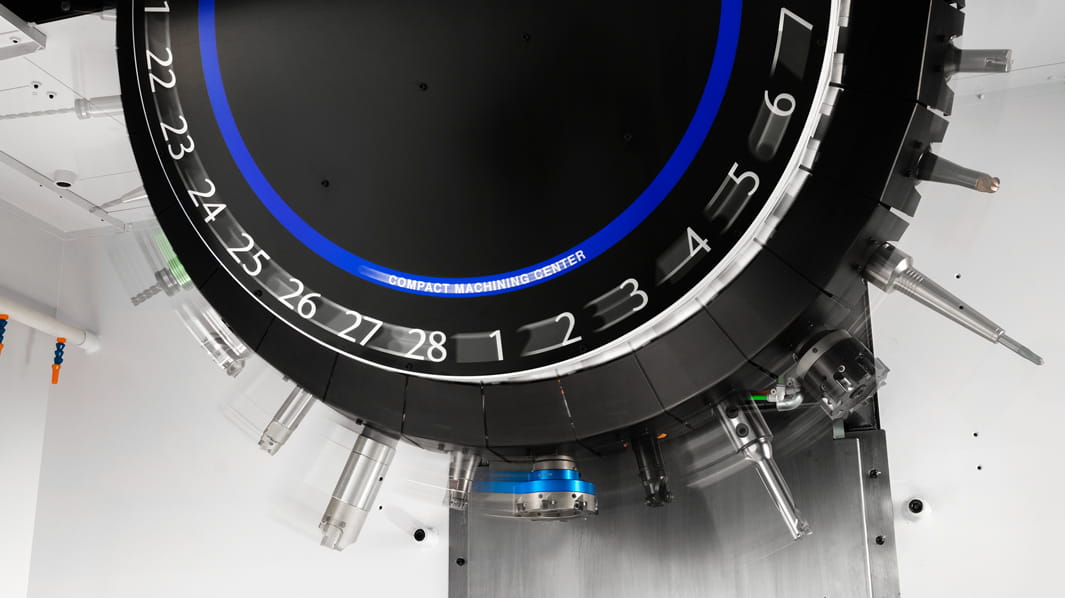

ATC is a function by which the tools in the machine's tool magazine are changed automatically. The ability to quickly change through a wide variety of tools reduces wasted time and effort and enables continuous machining.

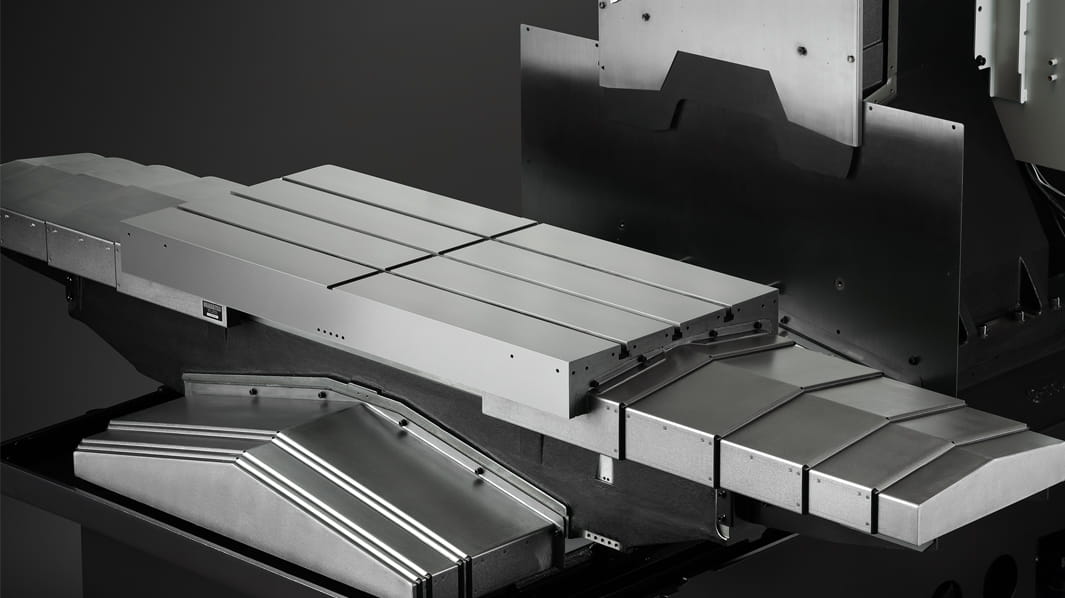

The machine table performs the central role of the machining center: fixing in place the workpiece to be machined. Tables will vary in their size, shape and function depending on the type and purpose of the machining center being used.