SPEEDIO Blue Technology Reducing Resource Waste by Preventing Machining Errors

In the manufacturing industry, prevention of machining errors is a major management issue. Machining errors not only waste a lot of resources, but also risk increased costs, delayed delivery, and other issues. In recent years, there has also been a need to work on reducing resource waste from the perspective of SDGs.

There are several ways that the manufacturing industry can reduce resource waste. In cutting, preventing machine breakdowns to avoid causing machining errors is particularly important. In this article, we will discuss methods to reduce resource waste in cutting, tips for preventing resource waste, and the performance of SPEEDIO Blue Technology that helps reduce resource waste.

Machining Errors Waste a Lot of Resources

A machining error refers to a situation where the product does not have the shape or accuracy specified in the drawing, or when machining has to be stopped. Machining errors occur in the cutting process for a variety of reasons.

The following are considered to be the main causes of machining errors.

- - Chip

- When metal chips generated during cutting are not properly evacuated, machining errors occur or the machine stops after a short time.

- - Vibration

- Intermittent vibrations that occur during cutting cause machining errors or damage to the machine.

- - Chipping

- Small chipping of the cutting tool's cutting edge cause machining errors. It can also lead to tool breakage.

- - Burr

- Metal burrs that occur during the cutting process cause a decline in machining accuracy or outflow of defects.

Chips and burrs generated during the machining process, as well as vibrations and cutting tool problems cause machining errors. Although machining errors are unavoidable in the cutting process, it is important to make efforts to prevent them from occurring.

The defective products that are generated end up being "undeliverable," resulting in waste of a lot of resources and energy, such as the raw materials and power required for machining. In addition to the machining cost, an increase in machined products that are "undeliverable" equals "no sales," and can put a strain on business operations.

Furthermore, an increase in incidents of products being delivered with unnoticed machining errors can impact the company's credibility, and should be avoided. Preventing machining errors is also a critical issue for maintaining and improving business operations.

Preventing Machining Errors and Breakdowns Is Vital to Preventing Resource Waste

Preventing machining errors and machine breakdowns is vital to preventing resource waste in the manufacturing industry. Moreover, from the perspective of Sustainable Development Goals (SDGs), resource waste due to machining errors must be reduced.

In recent years, many companies are now asking their business partners to work on the SDGs as well, in order to promote them across the supply chain. Reducing resource waste by preventing machining errors is an issue that must be consciously addressed not only from an environmental perspective but also from a management perspective.

So how can companies work to reduce resource waste? There are several ways to work on preventing machining errors that lead to resource waste. Let's take a closer look.

Improving Machining Accuracy

One way to work on preventing machining errors is to improve machining accuracy. Take measures to prevent the causes of machining errors given above and work to improve accuracy.

If there are many problems caused by chips and vibrations generated during the machining process, the cutting tools and cutting conditions must be reexamined. Make adjustments so that chips are properly evacuated and do not get caught in the tool or workpiece. It is vital to check cutting tools to prevent machining errors caused by chipping.

Machine Tool Maintenance

Perform routine maintenance to keep the machine in good working order.

In addition to routine maintenance such as checking for lubricating oil deterioration or low amounts of lubricating oil, checking for dirty air or coolant residues, and cleaning the tanks and filters, it is important to regularly perform maintenance according to the manufacturer's maintenance manual.

Introducing High-Performance Machine Tools

Introducing machine tools equipped with functions that reduce the occurrence of machining errors is also one way to reduce resource waste. If you are thinking of introducing or upgrading a machine tool, consider whether the machine tool can reduce the occurrence of machining errors in the selection process.

The performance of a machine tool that helps prevent machining errors will be introduced in the next section.

SPEEDIO Blue Technology Prevents Errors Before They Occur

SPEEDIO Blue Technology reduces resource waste through various maintenance functions that prevent machining errors and breakdowns. It also supports sustainable management through functions for the effective use of resources.

Machining Adjustment Support

SPEEDIO Adjust Tools support inexperienced users in machining settings by providing adjustment functions that ensure stable machining accuracy.

The machining parameter adjustment app makes it easy to set the optimal acceleration based on the table load weight as well as set the optimal parameters for hole machining.

With the machining mode settings, set the mode according to the required accuracy and time. Optimal operation is achieved without the need for difficult acceleration input or repeated adjustments.

Production Support Recovery Support

SPEEDIO Production Tools are available as a support function to maximize production efficiency. Through real-time monitoring with machining load monitoring and chip detection function, machining errors can be reduced.

The chip detection function detects chips caught between the spindle and holder during tool change without the use of sensors. Detecting unexpected chips caught during tool change prevents the outflow of defects.

In addition, the tool center point control function enables simultaneous 5-axis machining. Minute line segment machining capacity is four times higher than that of the previous model, minimizing delays even for CAM data with small tolerances.

Air-Assisted Tool Cleaning

In air-assisted tool cleaning, coolant fluid stored in the chamber is discharged using air pressure to effectively remove chips stuck to the holder. It has high discharge pressure and discharge flowrate. The cleaning function uses air pressure to eject the coolant fluid, eliminating the need for a dedicated pump and reducing energy waste.

Recovery Support

To prevent machining errors, it is also important to take preventive maintenance measures against accidents. SPEEDIO Recovery Tools use the ATC monitoring function and overload prediction function to predict the presence of tools and prevent machine stoppages before they occur.

In addition, the maintenance notice function supports the implementation of proper maintenance. With the maintenance notice function, notices are sent about when to apply grease and other maintenance work, to keep from forgetting to perform the maintenance essential to preventing breakdowns.

Effective Use of Resources

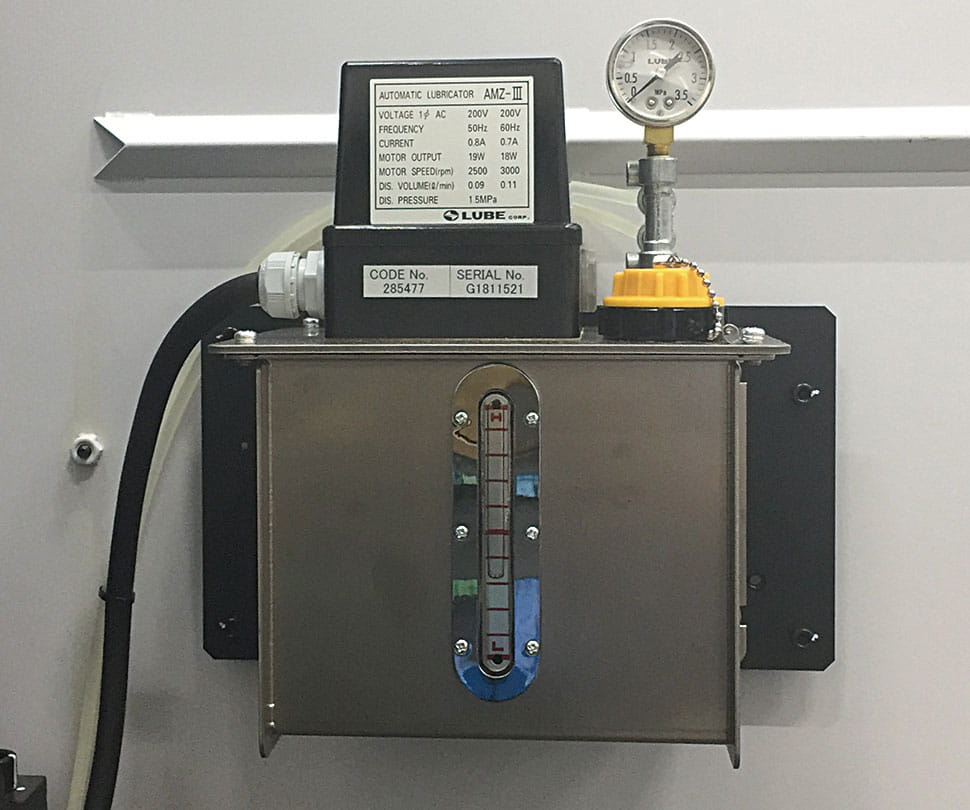

SPEEDIO also has the capacity to make effective use of resources. The optional automatic oil lubricator and automatic grease lubricator optimize the amount and timing of consumption and reduce coolant contamination through automatic oil/grease supply devices, thereby reducing resource waste.

Moreover, the tank with cyclone filter, available as a special option for the Coolant Through Spindle (CTS), has the advantage of not generating consumables.

SPEEDIO Blue Technology's Functions to Reduce Resource Waste Ensures Sustainable Production

With the current demand to fast-track initiatives toward the SDGs, the manufacturing industry must also be aware of environmentally responsible production. There are various initiatives that can be considered when aiming for manufacturing with less environmental impact. One of these is to reduce resource waste by reducing machining errors.

To prevent machining errors, it is important to perform fine machining adjustments and maintenance, and to prevent machine accidents. However, spending a lot of time on machining adjustments and maintenance leads to lower productivity.

SPEEDIO Blue Technology supports companies in solving these issues through a wide range of functions. It also helps create a pleasant work environment through effective use of resources and preventive maintenance against accidents.

Author: Miyuki Takahashi

Editor: EGGO CO., LTD.

Related Articles

Reduce Wasted Space With SPEEDIO Blue Technology