SPEEDIO Blue Technology Contributing to Environmentally Friendly Manufacturing by Reducing Energy Waste

With the growing threat of climate change, which is believed to be caused by global warming and the depletion of natural resources, companies are required to make efforts to reduce their impact on the global environment. The manufacturing industry uses a lot of power. Working to save energy not only contributes to society but also brings significant benefits in terms of cost reduction.

There are a variety of ways that the manufacturing industry can reduce energy consumption. One way to do this is to consider introducing energy-saving machine tools. In this article, we will explain why saving energy is necessary for machine tools, the key points for making machine tools more energy-efficient, and the SPEEDIO Blue Technology performance that contributes to reducing energy waste.

Why Energy Saving Is Necessary for Machine Tools

Manufacturing is an industry that creates products essential to people's lives. However, it must consume a lot of energy in order to meet these needs.

In recent years, efforts to reduce greenhouse gas emissions have been underway globally in response to resource depletion and climate change, which is believed to be the result of global warming. In Japan, the government has set a goal of carbon neutrality by 2050 and is calling on companies to reduce their greenhouse gas emissions as well.

According to the FY2022 Annual Report on Energy (Energy White Paper 2023) published by the Agency for Natural Resources and Energy of the Ministry of Economy, Trade and Industry, the corporate and business sector accounts for 63.5% of Japan's final energy consumption in 2021. Furthermore, the manufacturing industry accounts for the largest share at 68.6% of the corporate and business sector.

Based on these, it is clear that, even within the corporate and business sector where most of the energy in Japan is consumed, there are significant benefits for the manufacturing industry to work on saving energy. By reducing power consumption and working on energy saving, manufacturing companies can potentially reduce greenhouse gas emissions significantly throughout Japan.

Machine Tools Consume a Lot of Power

So how can manufacturing companies save energy? One effective approach is to upgrade machine tools that consume a lot of power to energy-saving ones.

Another benefit of upgrading machine tools to save energy is that it reduces electricity costs while being environmentally friendly.

The parts of machine tools that consume a lot of power include the spindle motor, servos (various feed axis other than the spindle), coolant, air compressor, and operation panel.

The spindle motor is the core of the machine tool. Because cutting and polishing are performed by the rotating spindle motor, it consumes a large amount of power during machining and when starting and stopping.

Servos are motors and amplifiers that precisely control the movement of each axis. A continuous power supply is required to control the movement of each axis.

Coolant is the liquid used to cool the heat generated during cutting. The pump drawing up the coolant consumes power.

The air compressor that supplies compressed air inside the machine tool uses power to maintain a constant air pressure. In addition, the operation panel, various sensors, work lights, and other parts, as well as the NC unit that controls all of these, consume power constantly.

All in all, machine tools consume a lot of power not only when machining a workpiece, but also when they are not cutting, to maintain internal temperature and condition.

Key Points for Making Machine Tools More Energy-Efficient

SPEEDIO Blue Technology reduces energy waste in machine tools that consume a lot of power, achieving top-class energy-saving performance.

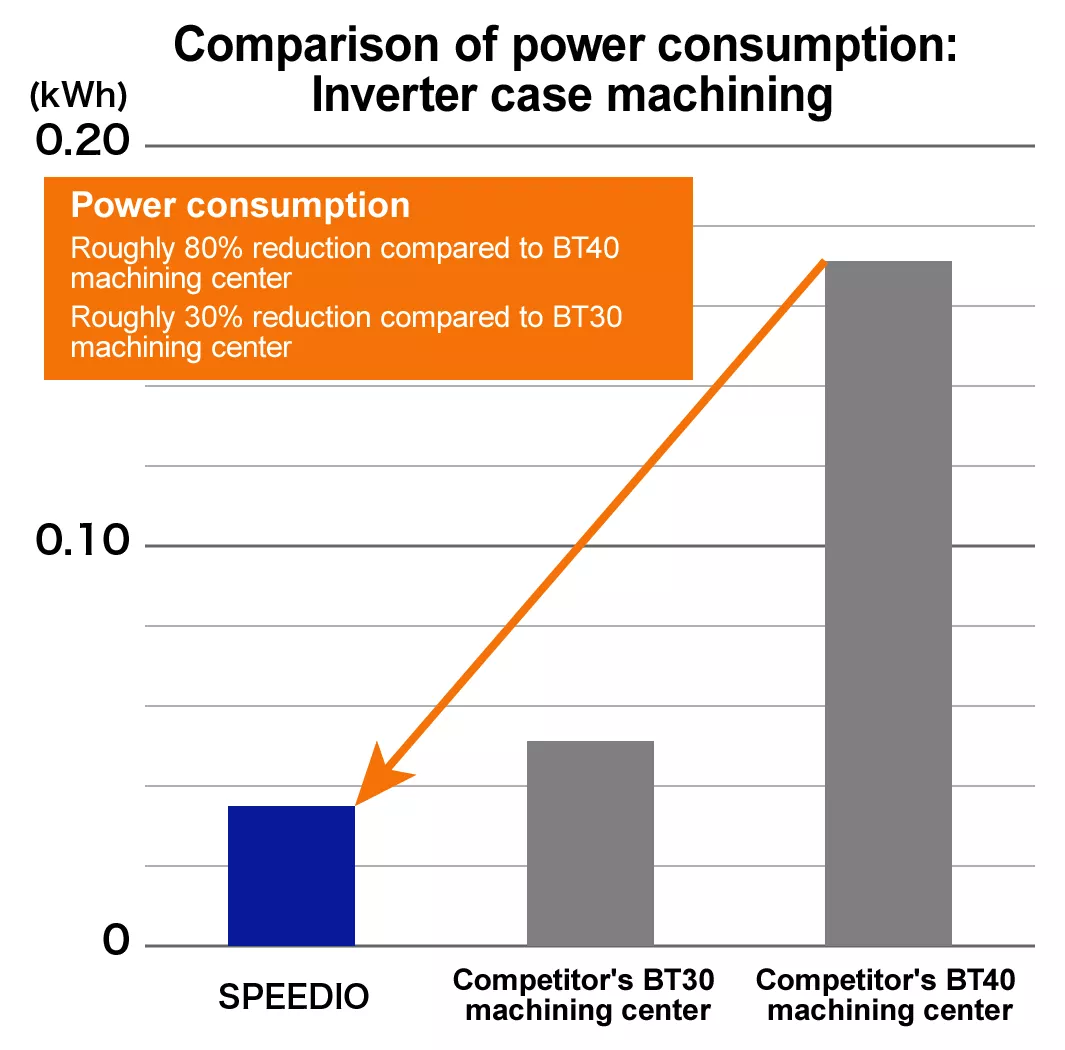

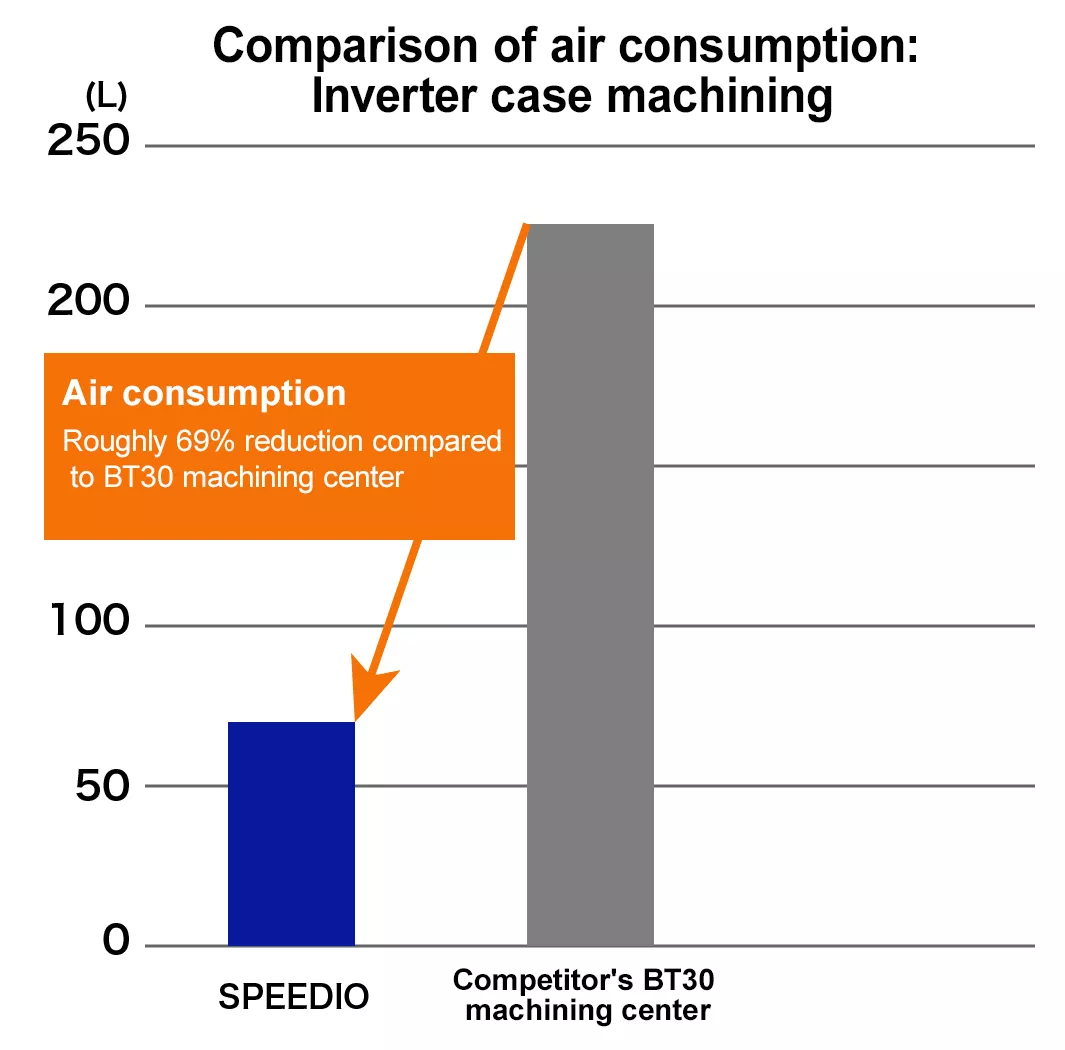

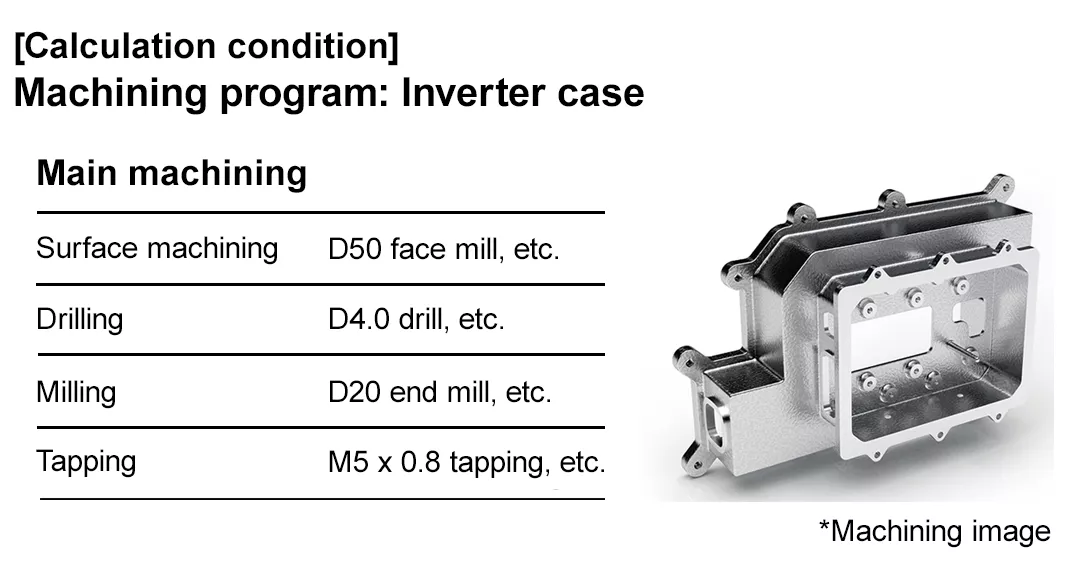

The graphs in the figure compare power consumption and air consumption using competitor products when machining parts of the inverter case used in EV. The data shows that power consumption is 80% lower than the competitor's BT40 machining center and 30% lower than the competitor's BT30 machining center.

Air consumption is also reduced by roughly 70% compared to the competitor's BT30 machining center.

In a typical manufacturing company, it is said that 55% of the power consumed comes from production equipment and 25% from compressors. Hence, reducing energy use in these areas is key to saving energy. SPEEDIO achieves top-class energy-saving performance by reducing the power and air consumption of the equipment.

Six Energy-Saving Features of SPEEDIO Blue Technology

Let's take a closer look at the top-class energy-saving performance of the SPEEDIO mentioned above.

Highly Efficient Spindle (IPM) Motor

Brother's unique high acceleration/deceleration type synchronous motor has a fast rotate/stop response, enabling highly efficient cutting with less power.

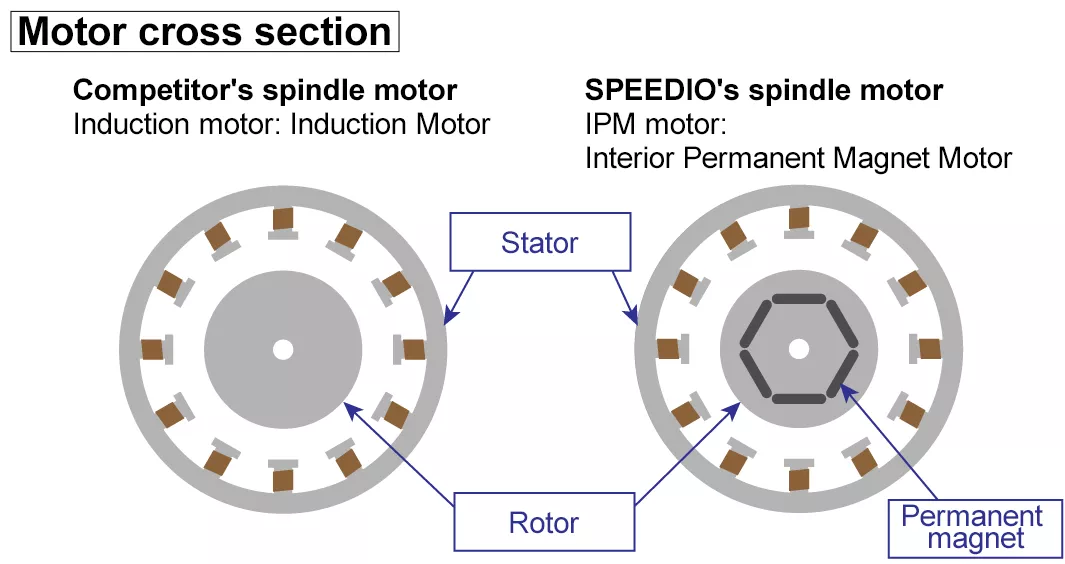

The reason for this lies inside the rotor of the highly efficient spindle (IPM) motor.

A permanent magnet is embedded inside the rotor of the IPM motor. The strong magnetic force of this permanent magnet enables the high speed and high output.

For induction motors, the following three steps are required for the motor to rotate.

<Steps until induction motor rotates>

- Current flows through the stator coil, generating a magnetic field in the stator

- Induced by the stator's magnetic field, current flows through the rotor after a short delay, generating a magnetic field in the rotor as well

- Motor rotates due to the magnetic fields in the stator and rotor

For IPM motors, step 2 is not required for the motor to rotate. SPEEDIO's IPM motors do not use power to generate a magnetic field in the rotor, making them more energy efficient than the induction motors used by many other companies.

Power Regeneration System

A key feature of SPEEDIO's energy-saving performance is its power regeneration system. A power regeneration system generates power when a motor decelerates and utilizes this generated power, similar to how a hybrid vehicle charges when decelerating.

For example, when machining an inverter case, 23% of the power consumed can be recovered as regenerative power. In tapping, which involves repeated starts and stops, a high regeneration rate of 50% can be achieved.

Energy-Saving NC Function

In addition to the highly efficient spindle motor and power regeneration system, which are major factors in achieving power savings, SPEEDIO also features an energy-saving NC. Specifically, the following functions reduce unnecessary power consumption during machine standby.

| Energy-Saving NC Function | Overview |

|---|---|

| Standby mode | Turns the servos off when the machine is not operated for the set time |

| Automatic work light off | Turns the work lights off automatically after the set time has elapsed |

| Automatic power off | Turns the NC power off automatically at the set time |

| Automatic display off | Turns the screen backlight off if no operation is performed for the set time or longer |

| Automatic coolant off | Turns the coolant pump off automatically after the set time has elapsed |

Machine tools consume a lot of power even during standby. SPEEDIO contributes to energy saving with functions that easily reduce energy waste when it is not machining a workpiece.

Air Purge

SPEEDIO has achieved air saving by reducing the air flow rate during air purge. Air purge is a function that prevents coolant from entering the spindle by blowing air.

To reduce the air flow rate during air purge, it uses a highly sealed structure that makes it difficult for coolant to enter, significantly reducing air consumption.

Spindle Air Blow

The spindle air blow, which removes foreign matter by blowing air during tool change, also reduces air consumption. Previously, the spindle air blow blows air over the entire area during tool change.

Now, thorough cleaning has been achieved with lower power consumption and air flow rate by blowing three times the amount of air only to the areas where it is needed.

Power Consumption App

The power consumption app is a tool for displaying the amount of power consumed classified according to purpose, such as servo, pump, and other devices. It can also calculate power consumption per cycle. Visualizing the data will help in working on further energy-saving efforts.

Equipped With Various Energy-Saving Functions, SPEEDIO Blue Technology Contributes to Reducing Energy Waste

SPEEDIO is equipped with various energy-saving functions, including a power regeneration system and energy-saving NC function. Performance improvements reduce energy waste by optimizing air consumption.

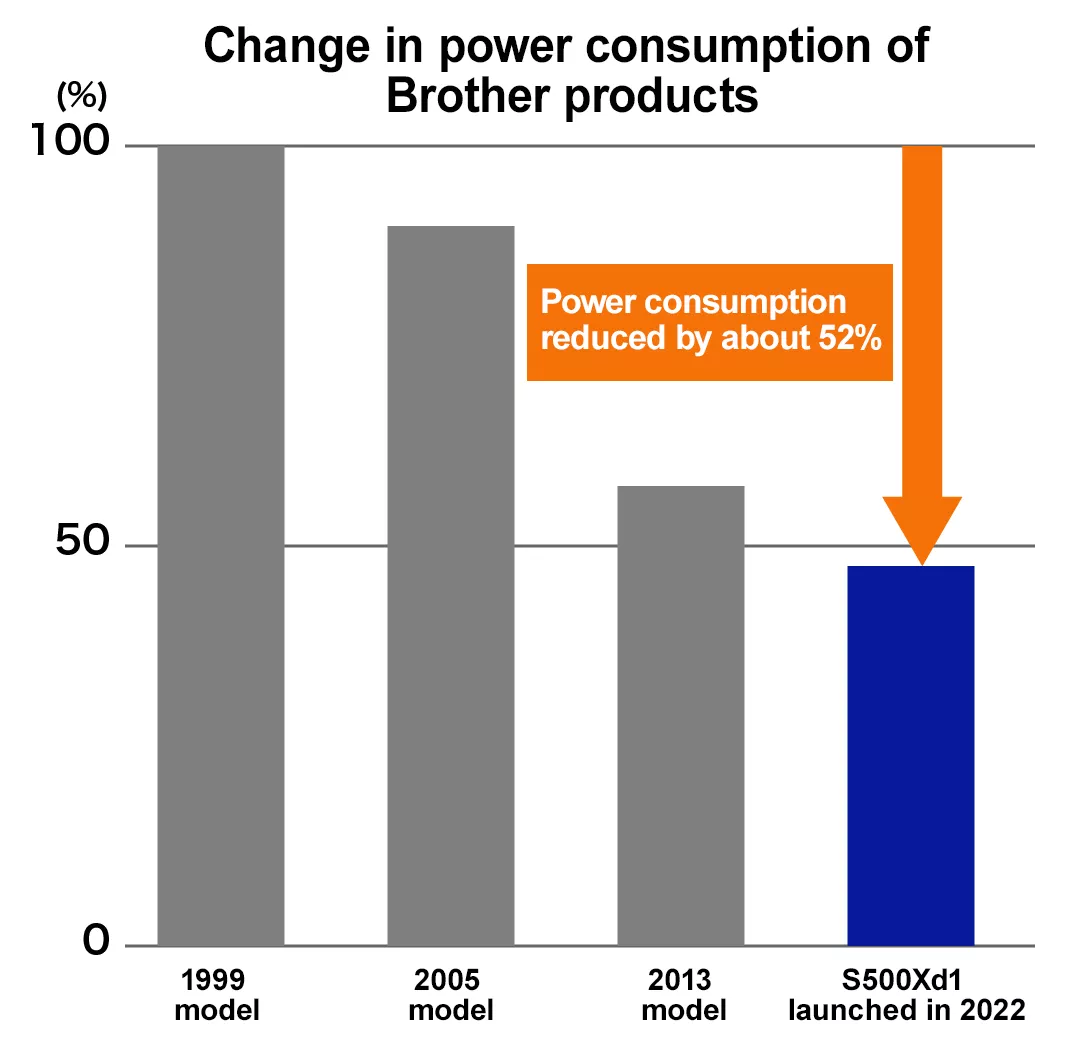

Comparing the power consumed per workpiece by the 1999-released TC-S2A and the 2022-released S500Xd1, power consumption dropped by 52%.

Reducing energy waste is a necessary initiative not only to reduce costs but also to lessen the impact on the global environment. In the energy-intensive manufacturing industry, each company will need to make efforts to reduce their energy use.

Upgrading to machine tools with better energy-saving performance can bring large benefits in terms of energy reduction. For companies thinking of introducing or upgrading machine tools, we recommend selecting products that focus on energy-saving performance together with improving production efficiency.

Author: Miyuki Takahashi

Editor: EGGO CO., LTD.

Related Articles

Reduce Wasted Space With SPEEDIO Blue Technology