After EMO 2025

Missed EMO? Discover our latest innovation at Our Showroom!

We are pleased to invite you to a special follow-up event featuring all the machines exhibited at EMO Hannover 2025. Discover our latest solutions designed especially for high-mix, low-volume production. In an exclusive, small-group setting, you will have the chance to speak directly with our technical experts. Don’t miss this opportunity to experience Brother’s newest innovations!

Event Overview

Event Name

After EMO 2025

Schedule

4 - 6 November, 2025 10:00 - 17:00

Application deadline

31 October 2025, 10:00

Exhibit Products

U500Xd2-5AX/100T, S700Xd2-5AX/100T, M200Xd1-5AX, M300Xd1-5AX, R650Xd1 40tools, Deburring Center DG-1

Exhibit Products

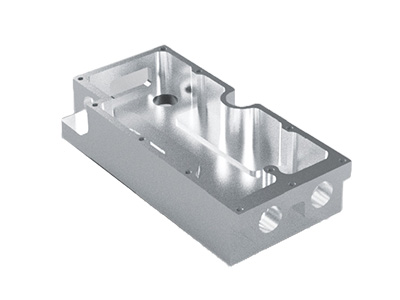

Universal Compact Machining Center SPEEDIO U500Xd2-5AX/100T

Newly developed 100-tool magazine achieves space saving and high productivity

Demonstration

Automation × High-mix, low-volume with EROWA Robot Compact 80

Compact Machining Center SPEEDIO S700Xd2-5AX/100T

Newly developed 100-tool magazine achieves space saving and high productivity

Demonstration

6-sided machining with LEHMANN's 2-axis table

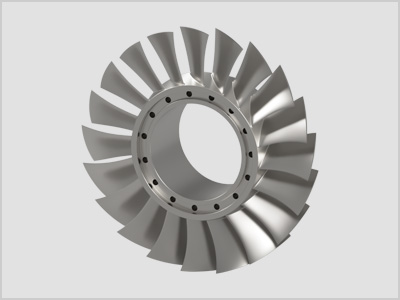

Compact Multi-Tasking Machine SPEEDIO M300Xd1-5AX

From Milling to Turning, equipped with 5-axis and spindle/turning synchronized control

Demonstration

Blisk workpiece machined using simultaneous 5-axis control

Compact Multi-Tasking Machine SPEEDIO M200Xd1-5AX

From Milling to Turning, equipped with 5-axis and spindle/turning synchronized control

Demonstration

Gear, Hobbing and Skiving, using spindle/turning synchronized control

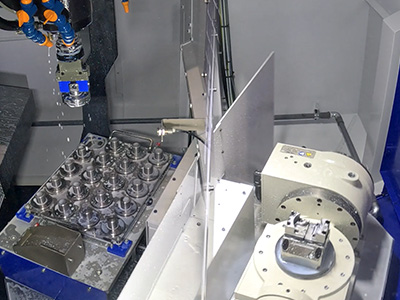

Pallet Changing Compact Machining Center SPEEDIO R650Xd1 40tools

Equipped with a "QT table", Brother's original pallet changer that avoids lift-up motion, new CNC, and tool magazine with up to 40-tool capacity to improve productivity at every production site.

Demonstration

Simple In-machine Automation with Schunk Work Gripper and Yukiwa’s 4th and 5th Axis Table

Deburring Center DG-1

Automates the manual deburring of die-cast materials in variable-volume production.

Even without programming or G-code knowledge and skills, you can generate processing paths with simple teaching.

Demonstration

Automatic deburring of die-cast materials

Wide Travel Compact Machining Center SPEEDIO W1000Xd2

Mounting a new 28-tool magazine promotes process integration for machining large workpieces. With maximum table loading capacity increased to 500 kg and increased Z-axis travel, the machine is widely suitable for a variety of production systems.

Register

Registration is closed.