EMO2025 HANNOVER

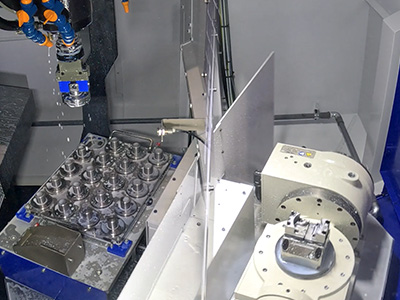

Precision Meets Innovation: The 100-Tool Game Changer

We are excited to showcase our new S700Xd2-100T and U500Xd2-100T for the first time in Europe. These products combine space saving with high productivity through Brother's unique mechanism. They can also be used in combination with a pallet changer to enable production over long periods of time, allowing efficient high-mix, small-lot production with reduced manpower requirements.

We will have many more products on display, so please stop by our booth and see the latest technologies and solutions!

Event Overview

Event Name

EMO HANNOVER 2025

Official Site

Schedule

22 - 26 September, 2025 9:00 - 18:00

Venue

Exhibit Products

U500Xd2-5AX/100T, S700Xd2-5AX/100T, M200Xd1-5AX, M300Xd1-5AX, R650Xd1 40tools, Deburring Center DG-1

Stand Location

Hall 15 - 14 A

Exhibit Products

Universal Compact Machining Center SPEEDIO U500Xd2-5AX/100T

Newly developed 100-tool magazine achieves space saving and high productivity

Demonstration

Automation × High-mix, low-volume with EROWA Robot Compact 80

Compact Machining Center SPEEDIO S700Xd2-5AX/100T

Newly developed 100-tool magazine achieves space saving and high productivity

Demonstration

6-sided machining with LEHMANN's 2-axis table

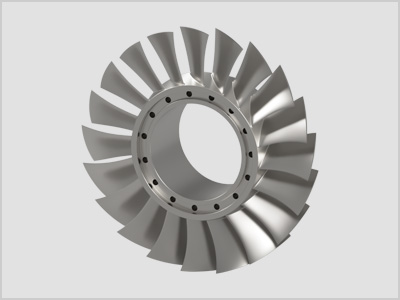

Compact Multi-Tasking Machine SPEEDIO M300Xd1-5AX

From Milling to Turning, equipped with 5-axis and spindle/turning synchronized control

Demonstration

Blisk workpiece machined using simultaneous 5-axis control

Compact Multi-Tasking Machine SPEEDIO M200Xd1-5AX

From Milling to Turning, equipped with 5-axis and spindle/turning synchronized control

Demonstration

Gear, Hobbing and Skiving, using spindle/turning synchronized control

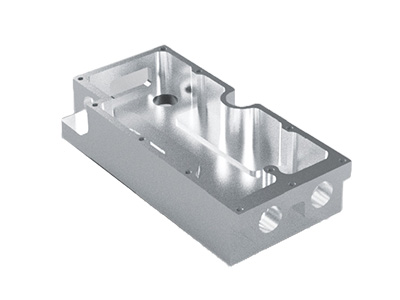

Pallet Changing Compact Machining Center SPEEDIO R650Xd1 40tools

Equipped with a "QT table", Brother's original pallet changer that avoids lift-up motion, new CNC, and tool magazine with up to 40-tool capacity to improve productivity at every production site.

Demonstration

Simple In-machine Automation with Schunk Work Gripper and Yukiwa’s 4th and 5th Axis Table

Deburring Center DG-1

Automates the manual deburring of die-cast materials in variable-volume production.

Even without programming or G-code knowledge and skills, you can generate processing paths with simple teaching.

Demonstration

Automatic deburring of die-cast materials