Achieving In-House Lathe Machining and Winning New Orders

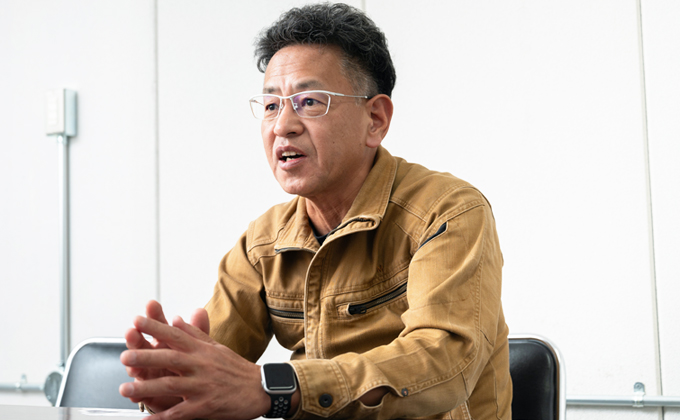

When President Morii first saw the BT30 machine in the showroom, he was uncertain. However, after actually using it, he realized that the BT30 had no issues and that it had better stability when the rotational speed was increased.

"Compared to the BT40, there were certainly areas where the load could not be applied, requiring some creativity, but once that problem was overcome, there were no further problems."

Their creative solutions involved limiting the cutting depth and working with as little light cutting as possible. President Morii indicated that these solutions will lead to the reduction of the deformation, warping, and distortion of machined aluminum products.

President Morii had the following praise for Brother machines.

"In addition to high-mix, small-lot production, we also handle mass-produced products. While manufacturing mass-produced products, we handle high-mix, small-lot products on a separate machine. Brother machines are perfect for efficiently managing operations in this way."

He cited the machine speed, ease of setup, and compact design as reasons for this, and also noted its high cost performance. In addition, he also believes the cost of support is reasonable.

"To survive in the world of aluminum machining requires meeting short delivery times and reducing cost as much as possible while providing high value-added products. Nowadays, companies must invest in quality management. It is important to make full use of machines that can reduce installation costs, such as Brother machines."

Lastly, President Morii said "even with a strong background of experience, if we are not constantly moving forward, we will quickly be overtaken by the competition." Brother will continue to work with MTM to fully support the company moving forward.

We look forward to a long-standing relationship in the future.

Featured Products

M300X3

Compact multi-tasking machine, equipped with turning and rotation axes, enables turning and milling processes through one-time chucking.

W1000Xd1

Combining one of the largest machining areas in the BT30 class and high productivity, this machine is capable of handling large workpieces and multi-part machining.

Equipped with a new NC controller for improved usability.