What Are "Barrel Tools," and How Do They Further Enhance 5-Axis Machining Center Performance? Implementation Criteria and Effectiveness

"Barrel tools" are used to extract higher performance out of 5-axis machining centers. With their ability to reduce finishing time to about half or one-third taken with conventional end mills, companies looking to speed up their machining are adopting these tools.

However, because barrel tools are relatively new, many professionals still lack familiarity about them. Here, we asked Mr. Tsuchiya, head of EMUGE-FRANKEN Japan—a company that develops barrel tools and currently offers a wide range of products—to provide an overview of barrel tools and key considerations for their adoption.

EMUGE-FRANKEN Yoshihiro Tsuchiya, Representative Director

Head of EMUGE-FRANKEN Japan.

Mr. Tsuchiya has been involved in the manufacturing industry for approximately 25 years. Drawing on his extensive knowledge and experience, he not only serves as company president but also works directly in sales, providing proposals and hands-on support to clients.

What Are Barrel Tools?

Barrel tools are a type of tool used with 5-axis machining centers. They are named after their barrel-shaped tip. Developed by EMUGE-FRANKEN's German headquarters in collaboration with OPEN MIND Technologies AG, barrel tools are now manufactured and sold by several companies.

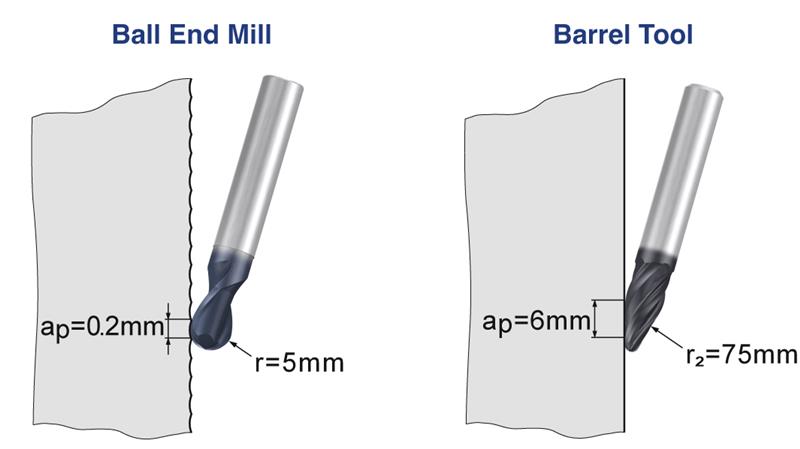

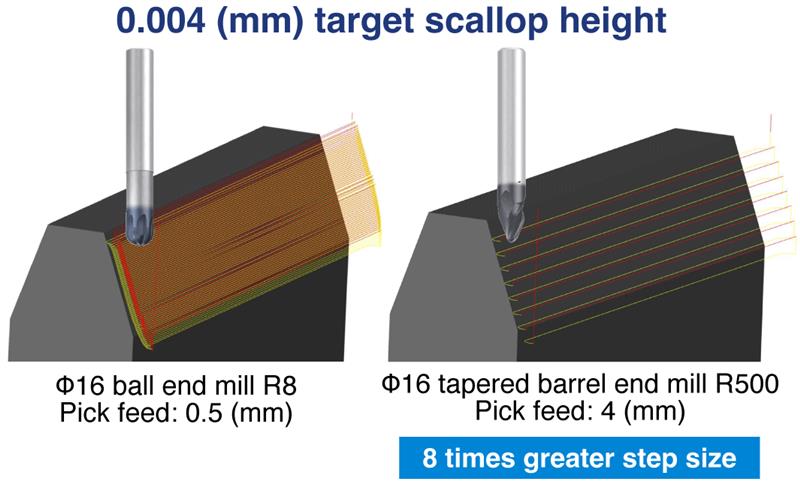

Their most significant difference from conventional end mills lies in their shape. While a typical ball end mill features a spherical radius cutting edge at the tip, barrel tools have a uniquely shaped peripheral cutting edge radius that is much larger than the tool diameter's radius. This large radius enables wider cutting pitches, achieving shorter machining times compared to ball end mills.

Barrel tools are relatively new to the industry, having been developed and launched by EMUGE-FRANKEN just 12 years ago. As a result, many professionals in the manufacturing industry have yet to use barrel tools or are still unfamiliar with them.

Benefits of Barrel Tools in Machining and Implementation Criteria

Barrel tools offer clear strengths and limitations. To fully appreciate their value after implementation, it's a good idea to first identify which processes could benefit from their use within your company. We asked Mr. Tsuchiya about the processes suited to barrel tools and the advantages of adopting them.

- What kind of companies are using barrel tools?

Tsuchiya: At EMUGE-FRANKEN, many of our clients are aircraft manufacturers and parts machining manufacturers. We tend to see more small and medium-sized businesses rather than large corporations.

- What type of machining makes the most of barrel tools?

Tsuchiya: They're good for finishing flat or gently curved surfaces. For example, they're useful for finishing large-sized parts such as aircraft parts or molds for making automotive parts. Companies that manufacture larger parts using ball end mills should find room to implement barrel tools.

Conversely, companies that mainly manufacture small parts or components may not see the same level of benefit.

- What kind of benefits can be expected from introducing barrel tools?

Tsuchiya: Finishing time can be reduced. Although it depends on the tool and machining used, companies currently using ball end mills can expect to complete machining in roughly half to one-third of the time.

Not only does machining time decrease, but machining quality should also improve. So, you can think of barrel tools as replacements for ball end mills.

- Can you share examples where introducing barrel tools led to significant results?

Tsuchiya: We've seen many success stories in our company. Aircraft parts manufacturers and automakers have expressed strong appreciation for the dramatic reduction in machining time. One company reduced their finishing process from six hours to just 1.5 hours.

The process using barrel tools is only 20-30% of the overall work, which isn't a huge proportion. However, this also means that the time savings for that 20-30% of the total work are quite substantial. This represents a major transformation.

In today's world, speed has an unmatched appeal. With numerous businesses struggling with rising labor costs and ongoing labor shortages, I believe they will experience significant benefits from adopting barrel tools.

- What percentage of companies have adopted both a 5-axis machining center and barrel tools?

Tsuchiya: Actually, not that many. In our case, only about 10-20% of client companies who own 5-axis machining centers. The number is gradually increasing, but it's still relatively low.

- That's a surprisingly low percentage. Why do you think that is?

Tsuchiya: There are several possible reasons, but one factor is the high barrier to adoption. In the first place, barrel tools show their true capabilities primarily in finishing operations. They may not deliver the same benefits in other types of machining.

Additionally, a CAD/CAM system compatible with barrel tools (software capable of handling everything from product design to machining program preparation) is necessary. For companies without such CAD/CAM system, the considerable initial cost can be a significant hurdle.

- Since they're tools designed for specific processes, it seems best to adopt them only after identifying the processes where they will make the most impact.

Tsuchiya: Exactly. That said, I've noticed growing interest from companies. With greater attention on 5-axis machining centers, I believe we'll see increased adoption of barrel tools in the near future.

Common Concerns Companies Face When Adopting Barrel Tools and Solutions

Even when companies express interest in barrel tools as mentioned above, some hesitate to adopt them due to concerns both before and after implementation. Mr. Tsuchiya shared common concerns and challenges that many companies face and ways to address them.

- Related to what we discussed earlier, what are the most common concerns for companies considering the adoption of barrel tools?

Tsuchiya: Many companies are not worried about the barrel tools themselves, but about other factors. The most common concern is probably the selection and implementation of CAD/CAM systems.

There aren't many CAD/CAM systems that support barrel tools. Although the number has been increasing in recent years, some companies may need to purchase new systems. If you plan to continue using your company's CAD/CAM system, you'll need to confirm whether they are compatible with barrel tools.

- So, what are some of the challenges you've come across after companies implement barrel tools?

Tsuchiya: We often hear that operators struggle to master the use of barrel tools.

Mastering barrel tools requires knowledge and proficiency in CAD/CAM. Moreover, with barrel tools, it can be difficult to visualize the right approach—which tools and machining paths to use for a given machining shape—without a certain level of experience.

In particular, many companies find it challenging to generate machining paths in-house. Many are unable to manage it on their own and ask us for support.

- Is there anything companies can do to address these issues?

Tsuchiya: First of all, carefully assess whether there are processes within your company where barrel tools could be applied. It's also a good idea to check whether you have suitable operators. One useful criterion is whether you have personnel with experience using 5-axis machining centers.

- If a company doesn't have such personnel in-house, would it be better to postpone adoption?

Tsuchiya: No, not at all. Of course, not every company has the required expertise in-house. However, some CAM suppliers offer operator training, and so do we. So it's okay to consider adoption with the understanding that you'll use such services.

Key Considerations When Choosing a Barrel Tool Manufacturer

Barrel tools are manufactured and sold by several manufacturers both in Japan and abroad. Mr. Tsuchiya says there are some key considerations for selecting a barrel tool manufacturer whose products align with your company's needs.

- What criteria should be used when choosing a barrel tool?

Tsuchiya: The most reliable method is to conduct test machining to confirm whether the tool can produce products with the accuracy that meets your company's needs. However, this can be difficult to determine before adoption, so it's probably best to choose based on the manufacturer.

More specifically, it's a safe bet to look closely at the barrel tool manufacturer's support program. Because barrel tools have a relatively short history, expertise is still being developed even within the manufacturing industry. To prepare for unexpected issues, I recommend choosing a manufacturer with extensive knowledge and experience of barrel tools.

- As a company involved in development, I imagine many companies choose your products when adopting barrel tools. What are the most common reasons clients choose your company?

Tsuchiya: There are two main reasons. First, as you mentioned, we were the first manufacturer to develop barrel tools. Second, we offer a wide range of tool options.

Barrel tools were developed by EMUGE-FRANKEN in collaboration with OPEN MIND Technologies AG. Because we're directly involved in development, we're confident in our deeper understanding of tool concepts and approaches compared to other manufacturers. In addition, we've been involved with barrel tools the longest. This seems to be one of our most appreciated strengths.

- You mentioned that your wide range of tool options is also a factor. How much variation is there in your product lineup?

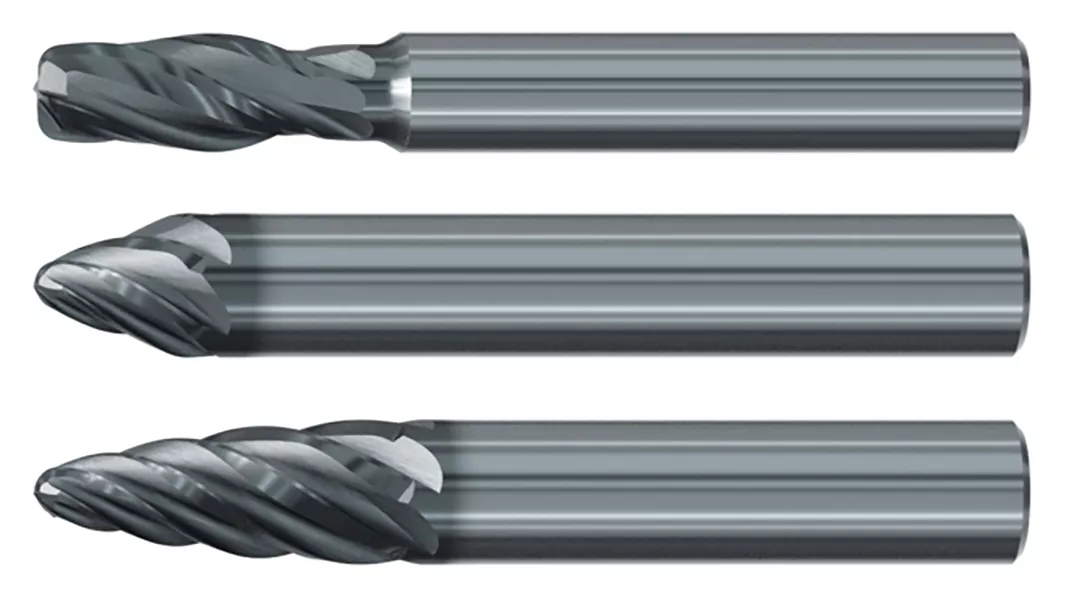

Tsuchiya: Our company offers tools across six categories: Barrel, Oval-VR, Oval-ER, Taper, Lens, and Insert. Furthermore, each category contains a large number of tools. Some people are genuinely surprised when they see what we have.

- What results can we expect from using your company's barrel tools in conjunction with Brother's SPEEDIO?

Tsuchiya: I believe you'll see significantly better results at a lower cost.

EMUGE-FRANKEN's headquarters is based in Germany, where machine tools tend to be larger. As a result, initial costs tend to be higher. In comparison, Brother Industries' SPEEDIO is attractive because it's a compact BT30 machine that also provides high rigidity. Given its performance, I feel that the price represents a very reasonable investment.

And so, I believe that, compared to machines with similar performance levels, implementing Brother Industries' SPEEDIO with our company's barrel tools can greatly improve operational efficiency while keeping costs down.

Implement Barrel Tools to Boost Speed and Set Your Business Apart

Barrel tools have a relatively short history compared to other tools, and not many companies have adopted them so far. However, this is precisely why implementing barrel tools can help set your business apart from other competitors and provide a competitive edge.

While several manufacturers produce barrel tools, EMUGE-FRANKEN's strength lies in its knowledge, experience, and extensive product lineup that only a development-driven company can offer. Even for businesses adopting barrel tools for the first time, you can be confident in making the most of this investment.

For companies thinking of implementing 5-axis machining centers and barrel tools, we encourage you to consider SPEEDIO and EMUGE-FRANKEN's barrel tools.

Author: Hiroko Shimokawa

Editor: EGGO CO., LTD.

Related Articles

What Is Cutting Speed? Calculation Formula and How to Determine Cutting Conditions