CNC-D00

Intuitive operation is possible with new support apps and vertical touch panel screen.

Wins iF DESIGN AWARD 2021

Features of CNC-D00

Home Screen

Data necessary for mass production is integrated as one.

Created a new home screen that serves as the start point of all operations. Data necessary for mass production is unified. Screens can be customized to be more user friendly.

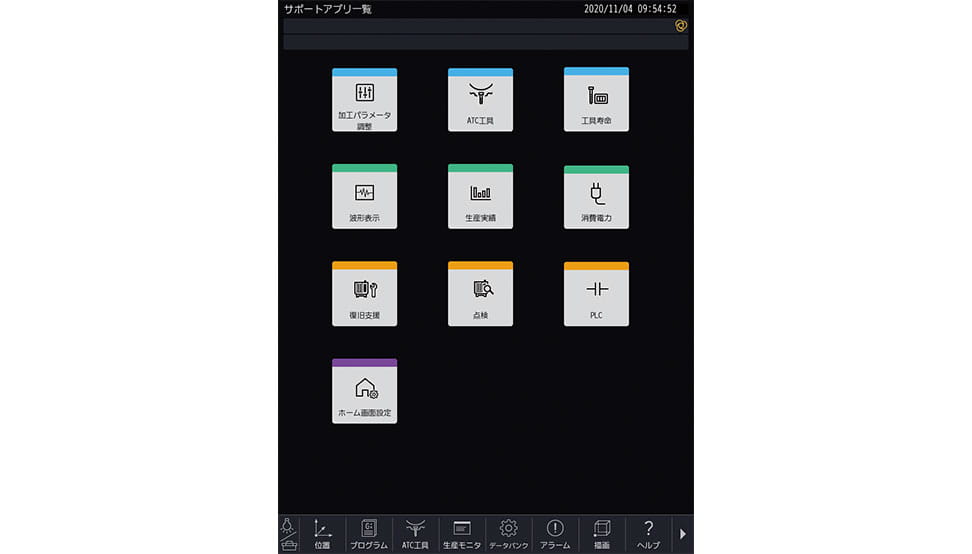

Support Apps

Easy-to use apps with no complicated operation.

Created new support apps with improved operability and visibility, such as an ATC tool app that enables all tool settings to be performed on one screen and a production result app that visualizes production results and operation state. Customers using the SPEEDIO for the first time do not have to learn complicated operations.

Conventional screens

Familiar conventional operation possible

Screens succeeding the configuration of the former model are available.

Even those familiar with the former model can use the new controller in the same way without learning new operation methods. Touch operation is also possible to suit all levels of onsite operators from new to experienced.

Four-support package solves problems at production sites

Setup Support

Efficient setup possible before machining Reduction in cumbersome setup procedure.

- ATC tool app

- Tool life app

- Menu programming

- QWERTY on-screen keyboard

- Running multiple blocks in MDI operation

- Expanded memory capacity

- Help key

- Memo pad / Calculator / File viewer

Adjustment Support

Reliable settings possible even by those with less experience Stable machining accuracy achieved by adjustment functions.

- Machining parameter adjustment app

- Machining mode setting

- Waveform display app

- Automatic heat expansion compensation

- Estimating loading weight

- Graphic display

- Tool length range setting

Production Support

SPEEDIO applicable to all types of production Production efficiency maximized to meet onsite needs

- Reduction in cycle time

- Machining load monitoring

- Power consumption app

- ATC monitoring

- Production result app

- Micro-segment processing capacity

- Enhanced network function

Recovery Support

Preventive maintenance prepared for possible future problems Reduction in downtime through reliable control

- Recovery support app

- Storing program alarm position

- Automatic backup

- Alarm log

- Overload prediction

- Maintenance notice

- Motor insulation resistance measurement

- Operation log

Specifications

-

NC Functions

Operation - Machine lock

- Restart

- Rapid traverse override

- Cutting feed override

- Background editing

- Screen shot

- Operation level

- External input signal key

- Spindle over

Programming - Absolute/ incremental

- Inch/ metric

- Coordinate system setting

- Corner C/ Corner R

- Rotational transformation

- Synchronized tap

- Subprogram

- Graphic display

Measurement - Automatic workpiece measurement *1

- Tool length measurement

High speed and high accuracy - Machining parameter adjustment

- High-accuracy mode A III

- High-accuracy mode B I (look-ahead 160 blocks)

- Backlash compensation

- High-accuracy mode B II, look-ahead 1,000 blocks, with smooth path offset

Monitoring - Machining load monitoring

- ATC monitoring

- Overload prediction

- Waveform display / waveform output to memory card

- Heat expansion compensation system II (X,Y,Z axes)

- Production performance

- Tool life / Spare tool

Maintenance - Tap return function

- Status log

- Alarm log

- Operation log

- Motor insulation resistance measurement

- Tool washing filter with filter clogging detection

Automation / Network - Computer remote

- OPC UA

- Auto notification

- Built-in PLC

- CC-link, master station

- CC-link, remote device station

- PROFIBUS DP, slave

- DeviceNet, slave

- PROFINET, slave

- EtherNet/IP, slave

Energy saving - Automatic power off

- Servomotor off standby mode

- Automatic coolant off

- Automatic work light off

- Chip shower off delay

Support Apps - Machining parameter adjustment

- ATC tool

- Tool life

- Waveform display

- Production performance

- Power consumption

- Recovery support

- Inspection

- PLC

Accessories - File viewer

- Memo pad

- Calculator

- Shortcut registration

- Display OFF

NC language mode only - Menu programming

- Local coordinate system

- Expanded workpiece coordinate system

- One-way positioning

- Inverse time feed

- Programmable data input

- Tool length compensation

- Cutter compensation

- Scaling

- Mirror image

- External sub program call

- Macro

- Operation in tape mode

- Multiple skip function

- Submicron command *2

- Interrupt type macro

- Rotary fixture offset

- Feature coordinate setting function *3

- Involute interpolation

Conversation language mode only - Operation program

- Schedule program

- Automatic tool selection

- Automatic cutting condition setting

- Automatic tool length compensation setting

- Automatic cutter compensation setting

- Automatic calculation of unknown number input

- Machining order control

*1: Measuring instrument needs to be prepared by users.

*2: When the submicron command is used, changing to the conversation program is disabled.

*3: There are restrictions on the models that can be equipped.

-

NC Unit Specifications

CNC model - CNC-D00

Control axes - 5 axes (X,Y,Z, two additional axes)

Simultaneously controlled axes Positioning - 5 axes (X,Y,Z, two additional axes)

Interpolation - Linear: 4 axes (X,Y,Z, one additional axes)

- Circular: 2 axes

- Helical/conical: 3 axes (X,Y,Z)

Least input increment - 0.001mm 0.0001inch 0.001°

Max.programmable dimension - ± 999999.999mm ±99999.9999inch

Display - 15-inch color LCD touch display

Memory capacity - 500 Mbytes (Total capacity of program and data bank)

External communication - USB memory interface, Ethernet, RS232C (optional)

No.of registrable programs - 4,000 (Total capacity of program and data bank)

Program format - NC language, conversation (changed by parameter), conversation from conversation program to NC language program available

- Number of "control axes" and/or "simultaneously controlled axes" are the maximum number of axes, which will differ depending on the destination country and the machine specifications.

- Ethernet is a trademark or registered trademark of XEROX in the United States.