SPEEDIO W1000Xd1

Wide Travel Compact Machining Center

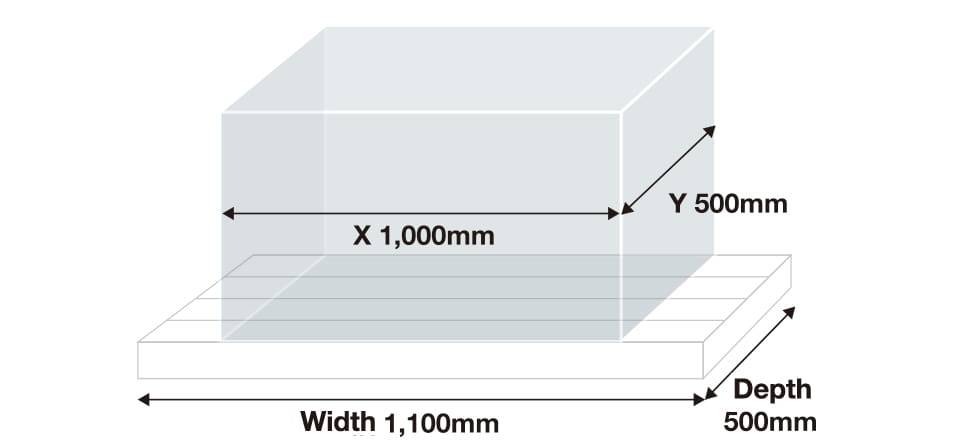

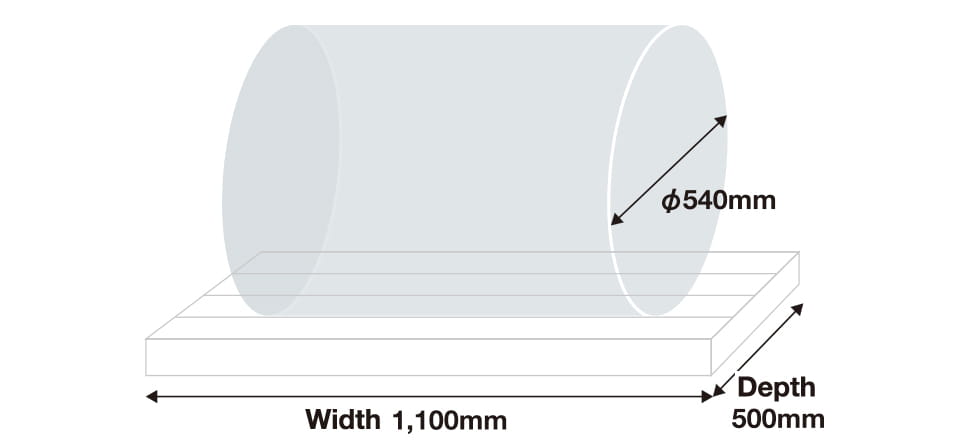

- Travels (mm): X: 1,000 Y: 500 Z: 300

- Max. spindle speed (min-1): 10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

- Tool storage capacity(pcs.): 14/ 21

"Machining larger workpieces using #30 machine" The release of the W1000Xd1 machining center sees an override in the conventional machining areas of #30 machines. Equipped with new NC controller

Information

Overview

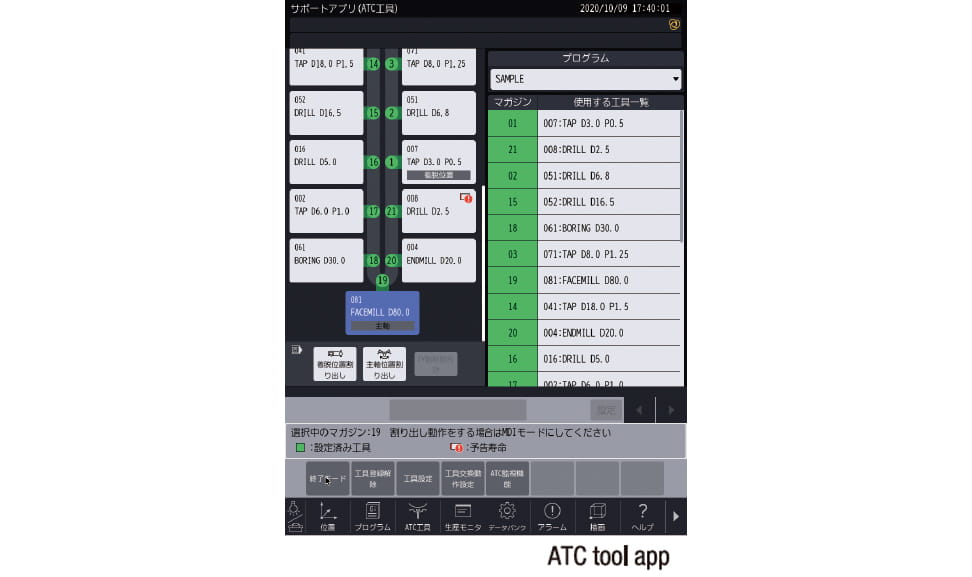

Intuitive operation is possible with new support apps and vertical touch panel screen.

Relevant functions are grouped according to purpose, such as setup and machining, leading to efficient operation.

Production and operation states are visualized, allowing faster understanding.

The new NC controller further improves work efficiency in pursuit of higher productivity.

Created a new home screen that serves as the start point of all operations.

Useful information like workpiece counter and tool life are displayed during mass production. New support app screens or conventional screens are opened from here.

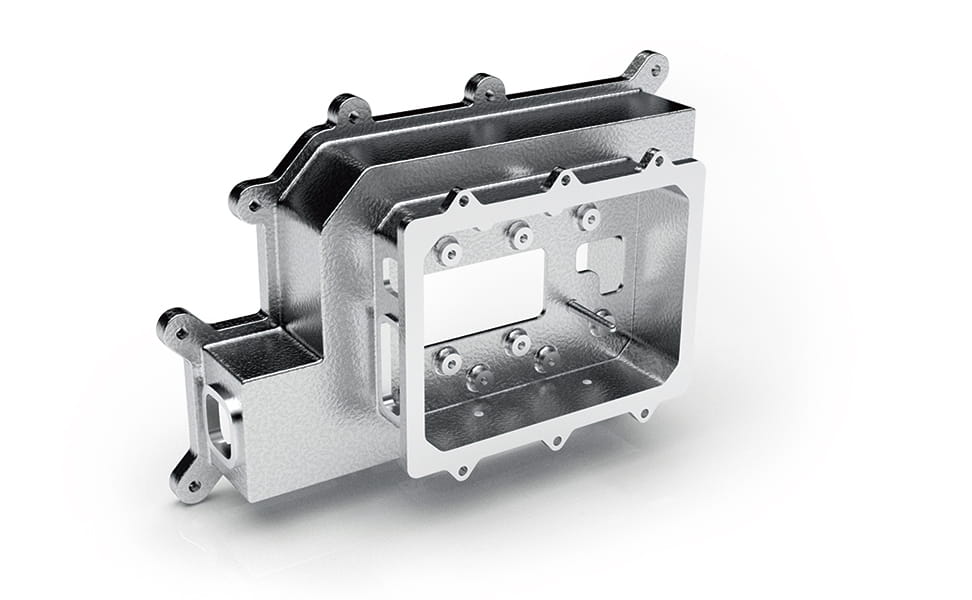

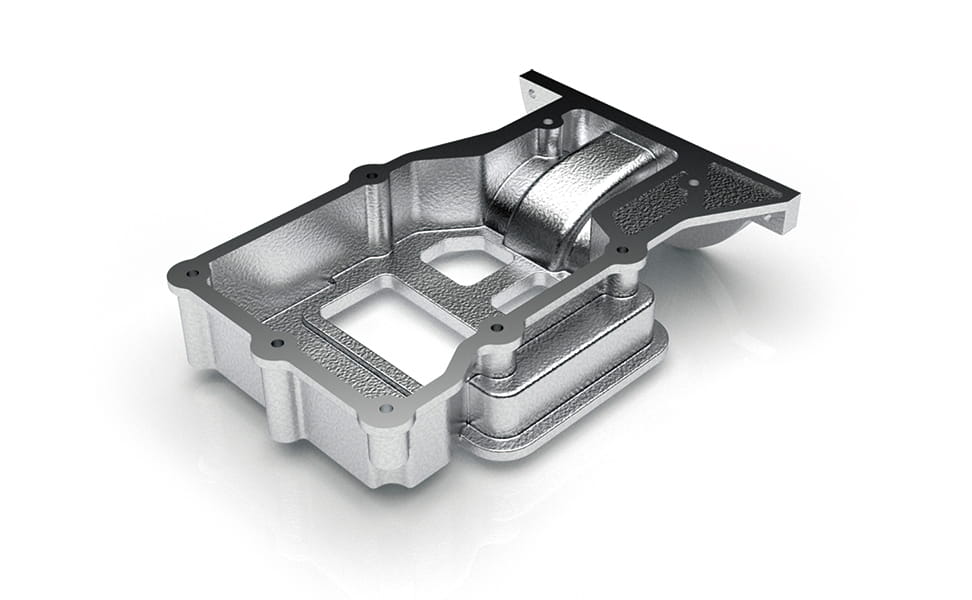

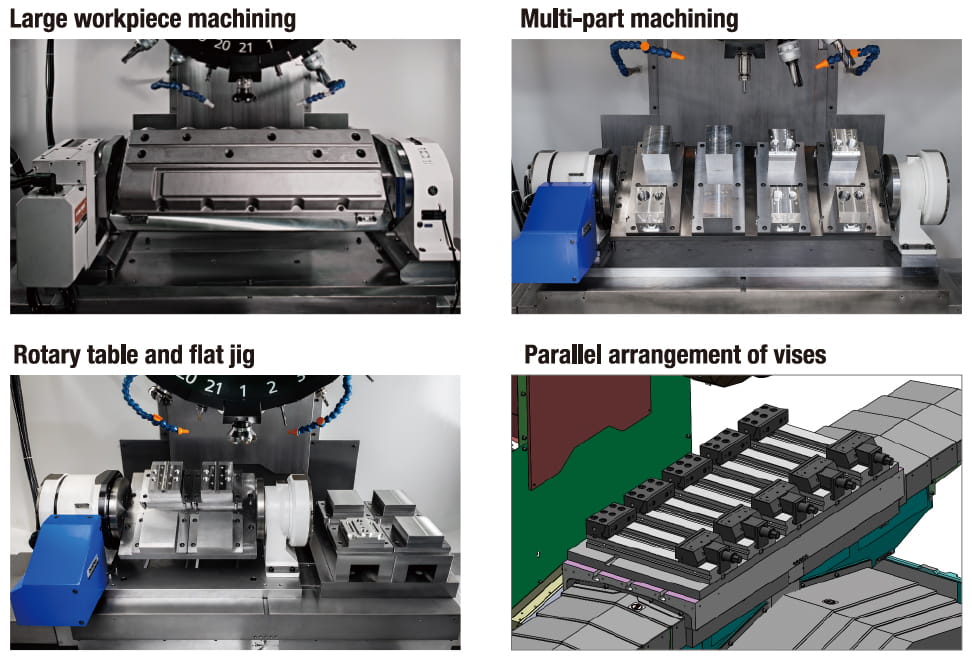

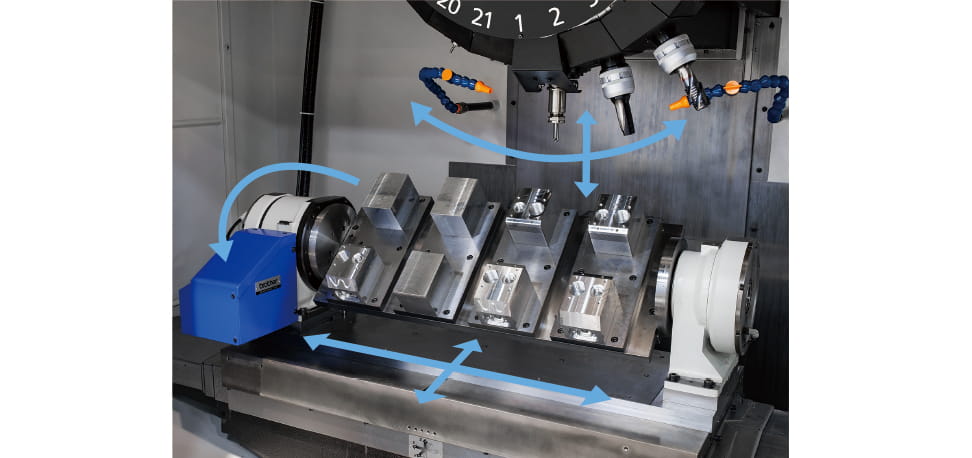

The wide machining area can accommodate constantly varying onsite needs, such as large workpiece machining, long-hour multi-part machining of small parts, multi-product small-volume production with various jigs placed side by side, which enhances the plantwide flexibility.

Ample X/Y-axes travels and sufficient loading capacity allow machining large workpieces and mounting a large jig, not available on conventional #30 machines.

Travels: X1,000 Y500

Work area size: X1,100 Y500

Max. loading capacity: 400 kg

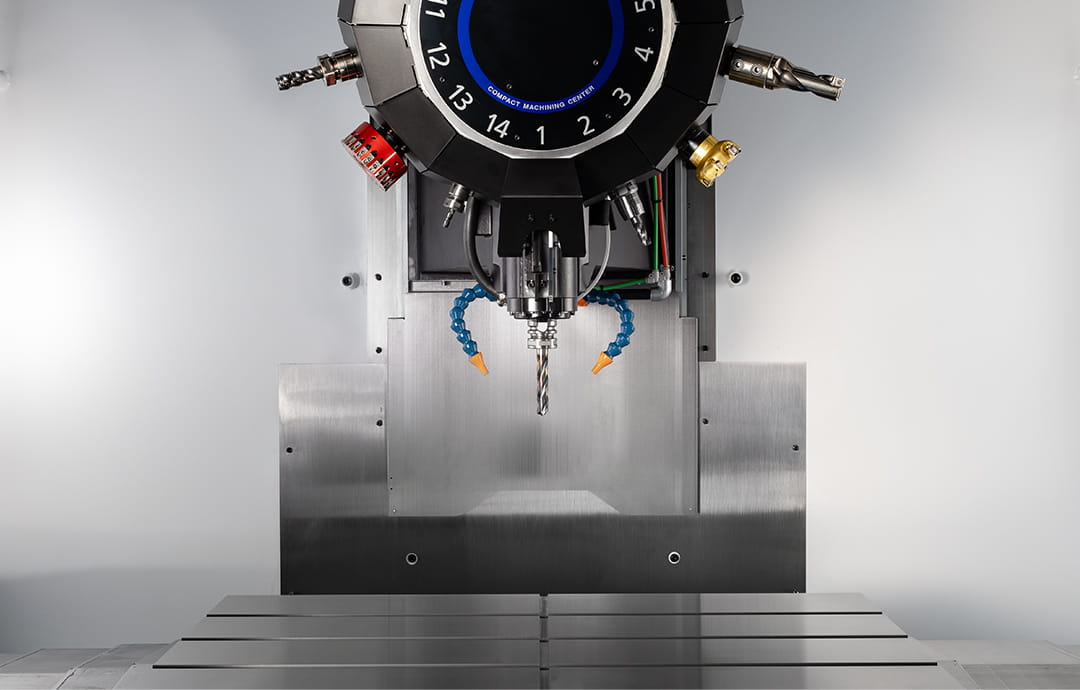

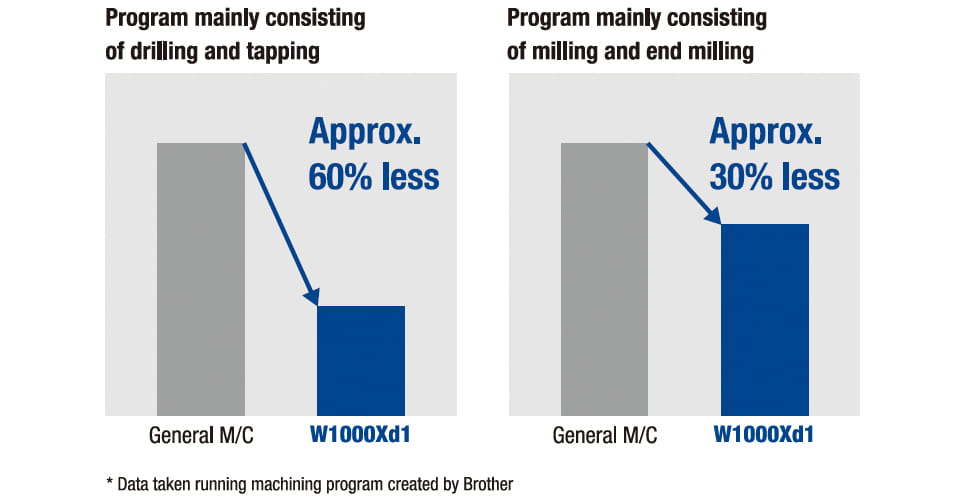

High speed, high acceleration, and high responsiveness have been the aim of machine/controller integrated development, and any wasted motion and time has been thoroughly eliminated to drive machine performance to the fullest and achieve high productivity.

Productivity has been further improved by optimally controlling operation with the new CNC-D00 controller and using a low inertial motor.

Improved by

3% or more (compared to previous model)

Tool change time has been reduced by increasing the speed of spindle start/stop, Z-axis up/down, and magazine operation.

Previous model → W1000Xd1

Chip - Chip: 1.4 S → 1.2 S

Previous model → W1000Xd1

Tool - Tool: 0.8S → 0.6 S

High rigidity based on a special design and use of a high-torque spindle motor achieve stable machining while demonstrating high machining capability.

Increased the weight of tools that can be mounted.

Combined with wide travels (X 1,000 mm, Y 500 mm), the machine is suitable for a wider variety of applications than ever.

*Changing parameter settings is required. (Tool indexing time is changed.)

The machine is compatible with 7 MPa high-pressure CTS in addition to 1.5 MPa CTS. Demonstrates its abilities in high-speed drilling or peck drilling.

* CTS: Coolant Through Spindle

A spindle motor with high torque in the medium- and high-speed range is used to achieve high-speed and highly efficient machining. The machine with high-torque spec. (optional) greatly improves the torque in the low-speed range, and demonstrates its abilities in heavy-duty steel machining.

High-torque spec. (optional)

Max. torque: 92Nm

Max. output: 26.2kW

Standard spec.

Max. torque: 40Nm

Max. output: 18.9kW

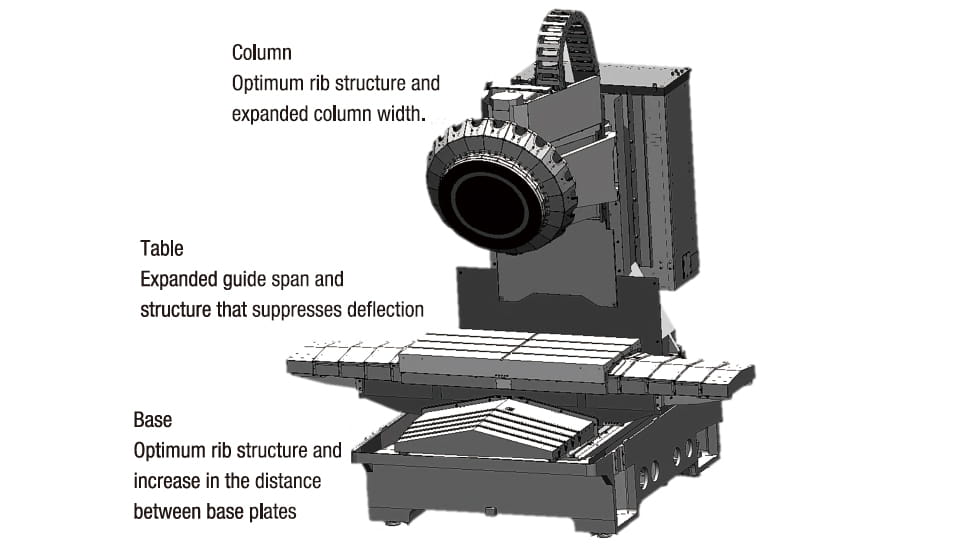

Backbone parts, such as the base, column, and table, have been specially designed through CAE analysis to secure high rigidity.

Specifications

Product Specification

W1000Xd1

Max. spindle speed [min⁻¹]

10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

Travels [mm (inch)]

X: 1,000 Y: 500 Z: 300

Tool storage capacity [pcs.]

14/ 21

Rapid traverse rate (XYZ axes) [m/min (inch/min)]

50 x 50 x 56

Required floor space [mm (inch)]

2,410 x 2,443

BT dual contact spindle(BIG-PLUS)

Optional

Coolant Through Spindle(CTS)

Optional

| item | W1000Xd1 / W1000Xd1 RD*9 | ||

|---|---|---|---|

| CNC unit | CNC-D00 | ||

| Travels | X axis [mm (inch)] | 1,000 (39.4) | |

| Y axis [mm (inch)] | 500 (19.7) | ||

| Z axis [mm (inch)] | 300 (11.8) | ||

| Distance between table top and spindle nose end [mm (inch)] | 180~480 (7.1~18.9) | ||

| Table | Work area size [mm (inch)] | 1,100 x 500 (43.3 x 19.7) | |

| Max.loading capacity (uniform load) [kg (lbs)] | 300[400] (661.3[881.8])*1 | ||

| Spindle | Spindle speed [min-1] | 10,000min-1 specifications : 1 - 10,000 10,000min-1 high-torque specifications(Optional) : 1 - 10,000 16,000min-1 specifications(Optional) : 1 - 16,000 |

|

| Speed during tapping [min-1] | MAX. 6,000 | ||

| Tapered hole | 7/24 tapered No.30 | ||

| BT dual contact system (BIG-PLUS) | Optional | ||

| Coolant Through Spindle (CTS) | 1.5 / 7.0 MPa Optional | ||

| Feed rate | Rapid traverse rate (XYZ-area) [m/min (inch/min)] | 50 x 50 x 56 (1,969 x 1,969 x 2,205) | |

| Cutting feed rate [mm/min (inch/min)] | X, Y, Z : 1 - 30,000 (0.04 - 1,181)*2 | ||

| ATC unit | Tool shank type | MAS-BT30 | |

| Pull stud type*3 | MAS-P30T-2 | ||

| Tool storage capacity [pcs.] | 14/21 | ||

| Max. tool length [mm (inch)] | 250 (9.8) | ||

| Max. tool diameter [mm (inch)] | ⌀110 (4.3) | ||

| Max. tool weight [kg (lbs)]*4 | 3.0(6.6) [4.0(8.8)] (Total tool weight : 25(55.1) for 14 tools, 35(77.2) for 21 tools) | ||

| Tool selection method | Random shortcut method | ||

| Tool change time*6 | Tool To Tool : 0.6sec. Chip To Chip : 1.2sec. |

||

| Electric motor | Main spindle motor (10 min/continuous) [kW]*7 | 10,000min-1 specifications : 10.1/7.0 10,000min-1 high-torque specifications(Optional) : 12.8/9.2 16,000min-1 specifications(Optional) : 7.4/5.1 |

|

| Axis feed motor [kW] | X,Y : 1.0 Z : 2.0 | ||

| Power source | Power supply | AC 200 to 230 V±10%, 3-phase, 50/60Hz±2% | |

| Power capacity (continuous) [kVA] | 10,000min-1 specifications : 9.5 10,000min-1 high-torque specifications(Optional) : 10.4 16,000min-1 specifications(Optional) : 9.5 |

||

| Air supply | Regular air pressure [MPa] | 0.4 - 0.6 (recommended value : 0.5MPa)*8 | |

| Required flow [L/min] | 45 | ||

| Machine dimensions | Height [mm (inch)] | 2,553 (100.5) | |

| Required floor space (with control unit door open) [mm (inch)] | 2,410 x 2,443[3,072] (94.9 x 96.2[121.0]) | ||

| Weight (including control unit, machine cover) [kg (lbs)] | 3,350 (7,386) | ||

| Accuracy*9 | Accuracy of bidirectional axis positioning (ISO230-2:1988) [mm (inch)] | 0.006 - 0.020 (0.00024 - 0.00079) | |

| Repeatability of bidirectional axis positioning (ISO230-2:2014) [mm (inch)] | Less than 0.004 (0.00016) | ||

- *1 Acceleration must be adjusted for X and Y axes.

- *2 When using high accuracy mode B.

- *3 Brother specifications apply to the pull studs for CTS.

- *4 Actual tool weight differs depending on the configuration and center of gravity. The figures shown here are for reference only.

- *5 Parameter settings must be changed. (Tool magazine indexing time will change.)

- *6 Measured in compliance with JIS B6336-9 and MAS011-1987.

- *7 Spindle motor output differs depemding on the spindle speed.

- *8 Regular air pressure varies depending on the machine specifications, machining program details, or use of peripheral equipment. Set the pressure higher than the recommended value.

- *9 Measured in compliance with ISO standards and Brother standards. Please contact your local distributor for details.

- *10 The machine needs to be equipped with a relocation detection device depending on the destination. Machines equipped with a relocation detection device come with “RD” at the end of the model name.

| CNC model | CNC-D00 | |

|---|---|---|

| Control axes | 5axes ( X, Y, Z, additional axes) | |

| Simultaneously controlled axes | Positioning | 5 axes (X, Y, Z, A, B) |

| Interpolation |

|

|

| Least input increment | 0.001 mm, 0.0001 inch, 0.001 deg. | |

| Max.programmable dimension | 9999.999mm, 999.9999inch | |

| Display | 15-inch color LCD touch display | |

| Memory capacity | 500 Mbytes (Total capacity of program and data bank) | |

| External communication | USB interface, Ethernet, RS232C(optional) | |

| No.of registrable programs | 4,000 (Total capacity of program and data bank) | |

| Program format | NC language, conversation (changed by parameter), conversion from conversation program to NC language program available |

|

| Standard NC functions |

|

|

| Optional NC functions |

|

|

- *1 Measuring instrument needs to be prepared by users.

- *2 When the submicron command is used, changing to the conversation program is disabled.

- * "Control axes" and "Simultaneously controlled axes" indicate the maximum number of axes. These are different depending on the destination or specifications.

- * Ethernet is a trademark or registered trademark of XEROX in the United States.

- * Functions listed under (NC) and (Conversation) are available only for NC programs and conversation programs respectively.

For options, please contact us.

Example