SPEEDIO R450Xd1

Pallet Changing Compact Machining Center

- Travels (mm): X: 450 Y: 320 Z: 305

- Max. spindle speed (min-1): 10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

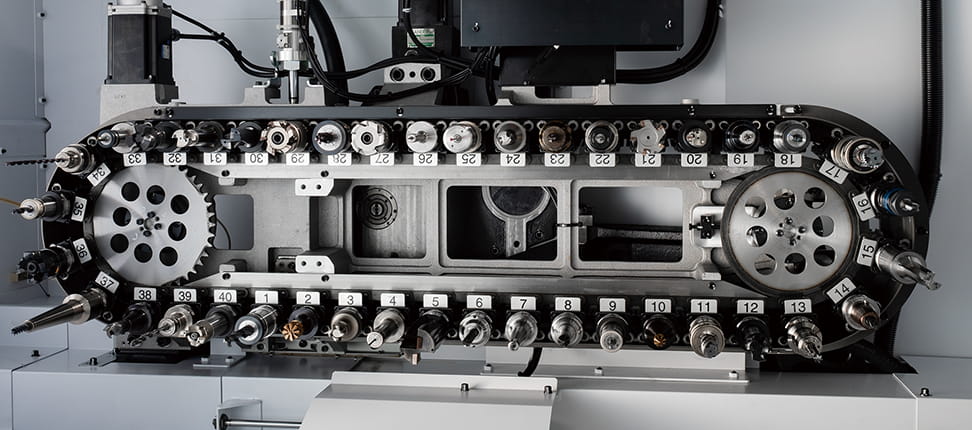

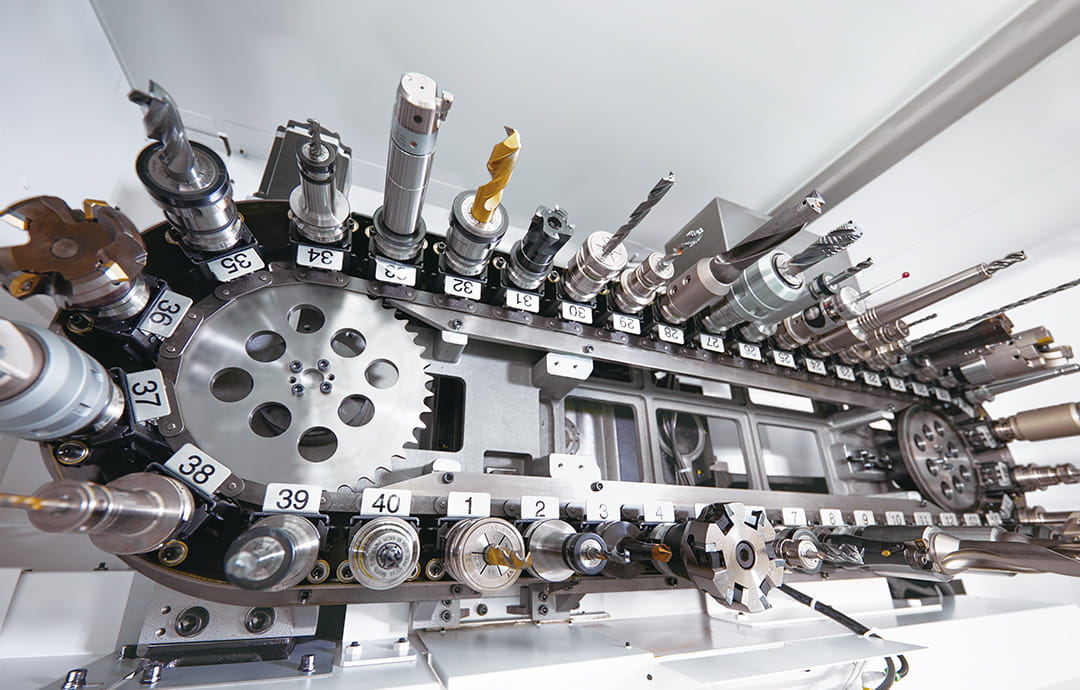

- Tool storage capacity(pcs.): 14/ 22/ 28

Select variant: R650Xd1 40tools

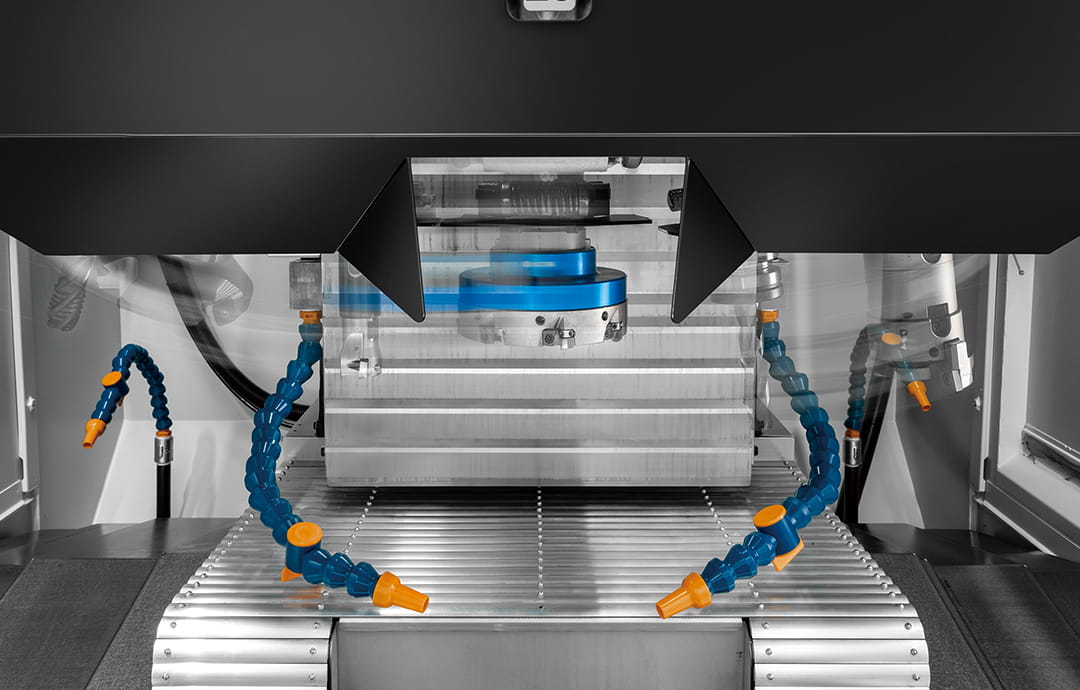

Equipped with a "QT table", Brother's original pallet changer that avoids lift-up motion, new CNC capacity to improve productivity at every production site.

Information

Overview

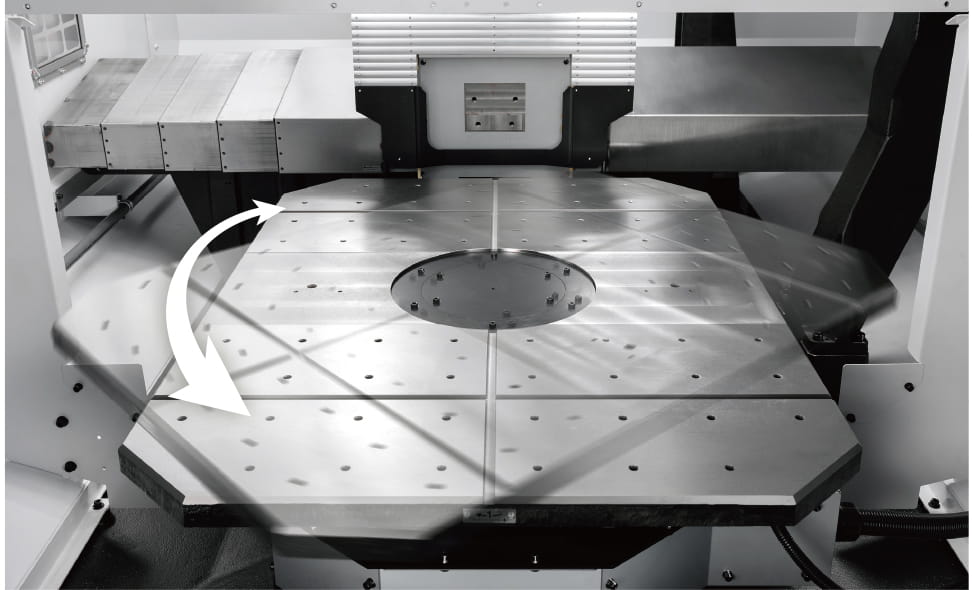

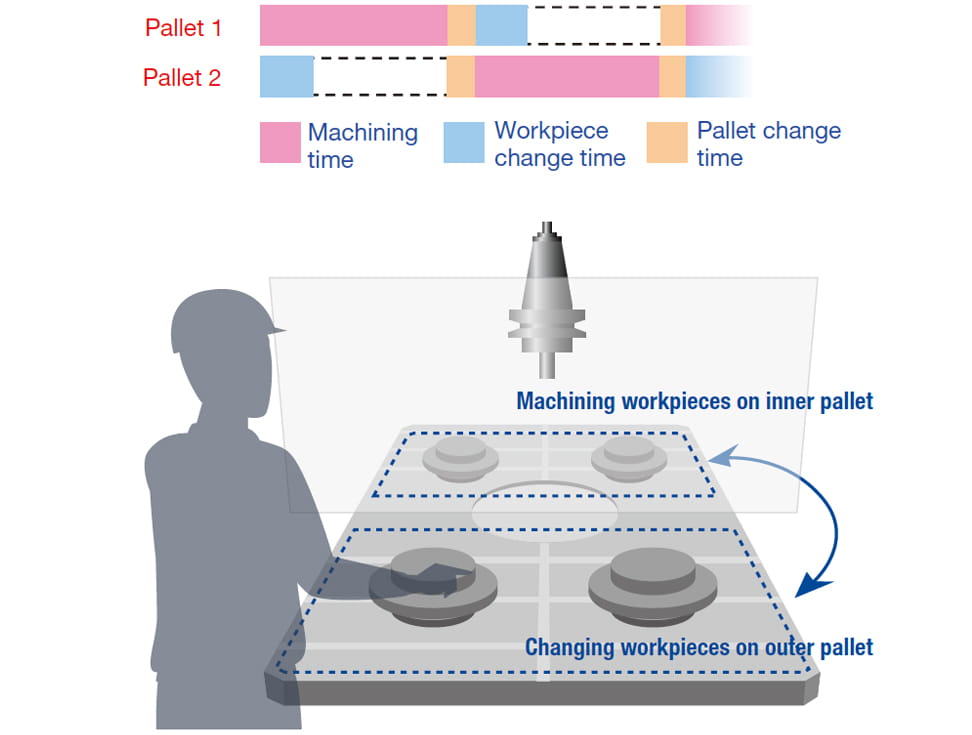

With a wide jig area and a high degree of reliability, the QT table enables non-stop machining to achieve high productivity.

Optimized acceleration/deceleration control achieves much faster pallet change.

Pallet change time

R450Xd1: 2.9 s → 2.7 s

R650Xd1: 3.4 s → 3.1 s

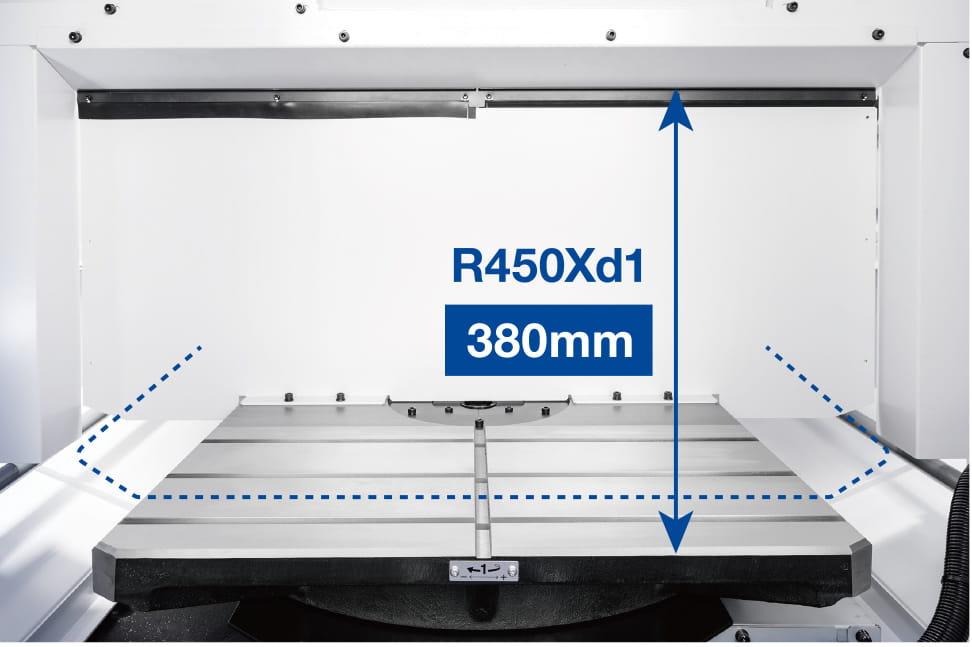

Max. jig height

R450Xd1: 350 → 380

R650Xd1: 420 → 450

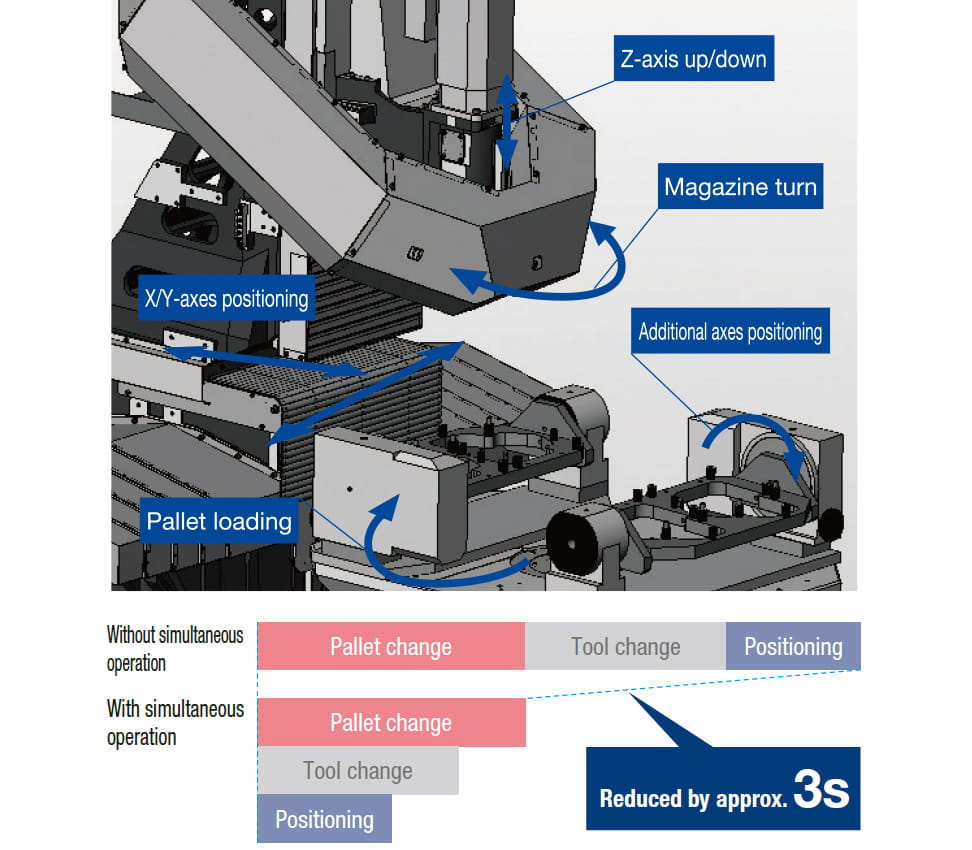

Overwhelming high productivity is achieved by utilizing advantages of machine/controller integrated development, including optimized and faster simultaneous operation and tool change operation.

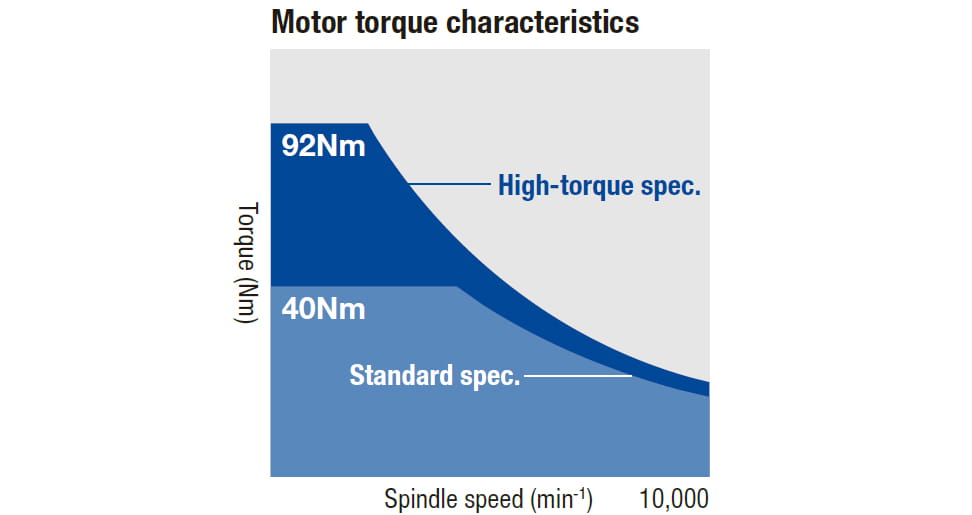

High-torque spec. (optional)

Max. torque : 92Nm

Max. output : 26.2kW

Standard spec.

Max. torque : 40Nm

Max. output : 18.9kW

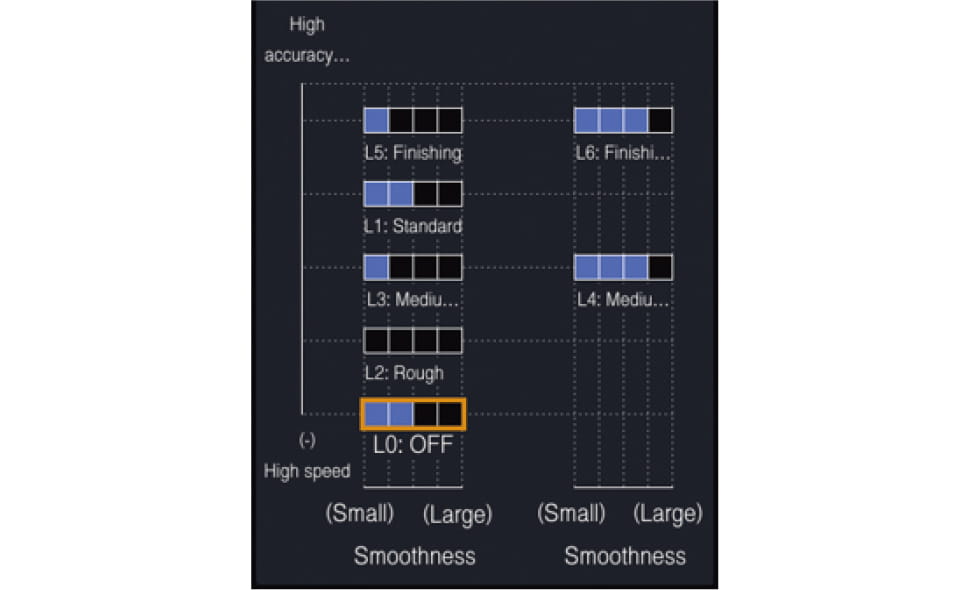

Simple setting for high accuracy mode

Machining accuracy/surface quality parameters can be adjusted by simple operation. This helps achieve high-quality machining easily.

High accuracy mode BI : Look-ahead 160 blocks

High accuracy mode BII (optional) : Look-ahead 1000 blocks

Specifications

Product Specification

R450Xd1

Max. spindle speed

10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

Travels

X: 450 Y: 320 Z: 305

Tool storage capacity

14/ 21/ 28

Rapid traverse rate (XYZ-area)

50 x 50 x 50

Required Floor Space

1,400 x 2,609

BT dual contact spindle(BIG-PLUS)

Optional

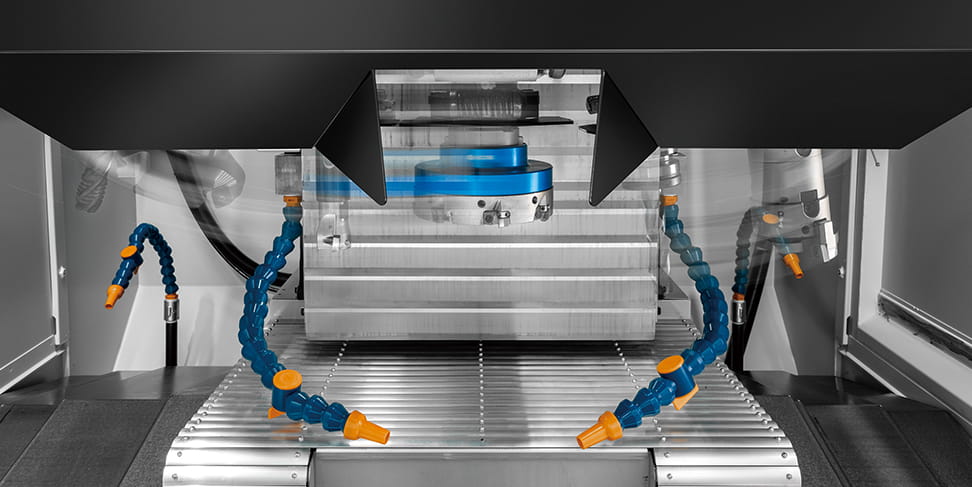

Coolant Through Spindle(CTS)

Optional

Low floor table

Optional

| item | R450Xd1 / R450Xd1 RD *12 | R650Xd1 / R650Xd1 RD *12 14/22/28 tool magazine |

R650Xd1 / R650Xd1 RD *12 40-tool magazine |

||

|---|---|---|---|---|---|

| CNC unit | CNC-D00 | ||||

| Travels | X axis [mm (inch)] | 450 (17.7) | 650 (25.6) | ||

| Y axis [mm (inch)] | 320 (12.6) *7 | 400 (15.7) | |||

| Z axis [mm (inch)] | 305 (12.0) | 305 (12.0) | 435 (17.1) | ||

| Distance between table top and spindle nose end [mm (inch)] | 200-505 (7.9-19.9) [280-585 (11.0-23.0) *8 |

250-555 (9.8-21.8) [350-655 (13.8-25.8) *8] |

250-685 (9.8-27.0) [350-785 (13.8-30.9) *8] |

||

| Table | Work area size [mm (inch)] | One face 600 x 300 (23.6 x 11.8) |

One face 800 x 400 (31.5 x 15.7) | ||

| Max.loading capacity (uniform load) [kg (lbs)] |

One face 120 (265) [200 (441) *6] |

One face 200 (441) [300 (661) *6] |

|||

| Position time [sec.] | 2.7 *11 | 3.1 *11 | |||

| Spindle | Spindle speed [min-1] |

10,000min-1 specifications : 1 - 10,000 16,000min-1 specifications(Optional) : 1 - 16,000 10,000min-1 high-torque specifications(Optional) : 1 - 10,000 |

|||

| Speed during tapping [min-1] | MAX. 6,000 | ||||

| Tapered hole | 7/24 tapered No.30 | ||||

| BT dual contact system (BIG-PLUS) |

Optional | ||||

| Coolant Through Spindle (CTS) | Optional | ||||

| Feed rate | Rapid traverse rate (XYZ-area) [m/min (inch/min)] |

50 x 50 x 50 (1,969 x 1,969 x 1,969) | |||

| Cutting feed rate [mm/min (inch/min)] |

X, Y, Z axis: 1 - 30,000 (0.04 - 1,181) *9 | ||||

| ATC unit | Tool shank type | MAS-BT30 | |||

| Pull stud type *4 | MAS-P30T-2 | ||||

| Tool storage capacity [pcs.] | 14/22/28 | 14/22/28 | 40 | ||

| Max.tool length [mm (inch)] | 200 (7.9) | 200 (7.9) | 250 (9.8) | ||

| Max.tool diameter [mm (inch)] | 80 (3.1) | 80 (3.1) | 55 (2.1) / 125 (4.9) No adjacent tool |

||

| Max.tool weight [kg (lbs)] *1 | 3.0 (6.6) |

3.0 (6.6) |

4.0 (8.8) |

||

| Tool selection method | Random short cut method | Random short cut method | Double arm method (random closet path) |

||

| Tool change time *5 | Tool To Tool [sec.] | 0.6 / 0.7 (14-tool / 22 or 28 tool) |

0.6 / 0.8 (14-tool / 22 or 28 tool) |

0.9 | |

| Chip To Chip [sec.] | 1.3 / 1.5 (14-tool / 22 or 28 tool) |

1.4 / 1.5 (14-tool / 22 or 28 tool) |

2.5 | ||

| Electric motor | Main spindle motor (10 min/continuous)[kW] *2 |

10,000min-1 specifications : 10.1/7.0 16,000min-1 specifications(Optional) : 7.4/5.1 10,000min-1 high-torque specifications(Optional) : 12.8/9.2 |

|||

| Axis feed motor [kW] | X, Y axis : 1.0 , Z axis : 1.8 | ||||

| Power source | Power supply | AC 200 to 230 V±10%, 3-phase, 50/60Hz±2% | |||

| Power capacity (continuous) [kVA] | 10,000min-1 specifications : 9.5 16,000min-1 specifications(Optional) : 9.5 10,000min-1 high-torque specifications(Optional) : 10.4 | ||||

| Air supply | Regular air pressure [MPa] | 0.4 - 0.6 (recommended value: 0.5MPa *10) | |||

| Required flow [L/min] | 45 | 45 | 100 | ||

| Machine dimensions | Height [mm (inch)] | 2,584 (101.7) | 2,704 (106.5) | ||

| Required floor space *13 [with control unit door open] [mm (inch)] |

1,400 x 2,609 [3,448] (55.1 x 102.7 [135.7] ) |

1,830 x 3,029 [3,868] (72.0 x 119.3 [152.3] ) |

2,145 x 3,029 [3,868] (84.4 x 119.3 [152.3] ) |

||

| Weight (including control unit, machine cover) [kg (lbs)] | 2,750 (6,063) | 3,550 (7,826) | 4,150 (9,149) | ||

| Accuracy*3 | Accuracy of bidirectional axis positioning (ISO230-2:1988) [mm (inch)] | 0.006 - 0.020 (0.00024 - 0.00079) | |||

| Repeatability of bidirectional axis positioning (ISO230-2:2014) [mm (inch)] | Less than 0.004 (0.00016) | ||||

| Front door | 2doors | ||||

| Standard accessories | Instruction Manual (DVD 1 set), leveling bolts (4 pcs.) [R650Xd1: 5 pcs.], leveling plate (4 pcs.) [R650Xd1: 5 pcs.] |

||||

- *1 Actual tool weight differs depending on the configuration and center of gravity. The figures shown here are for reference only.

- *2 Spindle motor output differs depending on the spindle speed.

- *3 Measured in compliance with ISO standards and Brother standards. Please contact your local distributor for details.

- *4 Brother specifications apply to the pull studs for CTS.

- *5 Measured in compliance with JIS B6336-9 and MAS011-1987.

- *6 Can be increased up to R450Xd1: 200kg, R650Xd1: 300kg (one face) by changing the parameter. Please consult us separately.

- *7 When using the hydraulic rotary joint, the Y-axis travel becomes 290 mm.

- *8 Values when the low-floor table is selected.

- *9 When using high accuracy mode B.

- *10 Regular air pressure varies depending on the machine specifications, machining program details, or use of peripheral equipment. Set the pressure higher than the recommend value.

- *11 When table loading on one face is R450Xd1: 120kg, R650Xd1: 200kg.

- *12 The machine needs to be equipped with a relocation detection device depending on the destination. Machines equipped with a relocation detection device come with "RD" at the end of the model name.

- *13 The value does not include the coolant tank or chip conveyor.

- *14 When the turning diameter enlargement option is selected.

| Item | R450Xd1 | R650Xd1 |

|---|---|---|

| Type | 0 deg./180 deg. turntable system | 0 deg./180 deg. turntable system |

| Table dimension [mm (inch)] | One face 600 x 420 (23.6 x 16.5) | One face 800 x 535 (31.5 x 21.1) |

| Max. turning diameter [mm (inch)] | D1,020 (40.2) [D1,100 (43.3)] *14 | D1,250 (49.2) [D1,300 (51.2)] *14 |

| Max. jig height [mm (inch)] | 300 (11.8) [380 (15.0)] *8 | 350 (13.8) [450 (17.7)] *8 |

| Table work area size [mm (inch)] | One face 600 x 300 (23.6 x 11.8) | One face 800 x 400 (31.5 x 15.7) |

| Max. loading capacity [kg (lds)] | One face 120 (265) [200 (441)] *6 | One face 200 (441) [300 (661)] *6 |

| Rated table load inertia for turning axis [kg·m2] | One face 14.2 [23.5] *6 | One face 35.8 [53.7] *6 |

| Table turning system | AC servo motor(1kW) Worm gear (total speed reduction ratio:1/50) |

AC servo motor(0.82kW) Worm gear (total speed reduction ratio:1/60) |

| Table position time | 2.7 *11 | 3.1 *11 |

| Table change repeatability [mm (inch)] |

0.005 (0.0002) (in the X,Y, and Z axes directions 270(10.6) from the center of rotation) |

0.005 (0.0002) (in the X,Y, and Z axes directions 335(13.2) from the center of rotation) |

- * Quick Turn table is a turntable type 2-face pallet changer.

| CNC model | CNC-D00 | |

|---|---|---|

| Control axes | 7 axes (X, Y, Z, four additional axes) | |

| Simultaneously controlled axes | Positioning | 5 axes (X, Y, Z, A, B) |

| Interpolation | Linear : 4 axes (X, Y, Z, one additional axis) Circular : 2 axes Helical/Conical : 3 axes (X, Y, Z) |

|

| Least input increment | 0.001mm、0.0001inch、0.001 deg. | |

| Max.programmable dimension | ±999999.999mm、±99999.9999inch | |

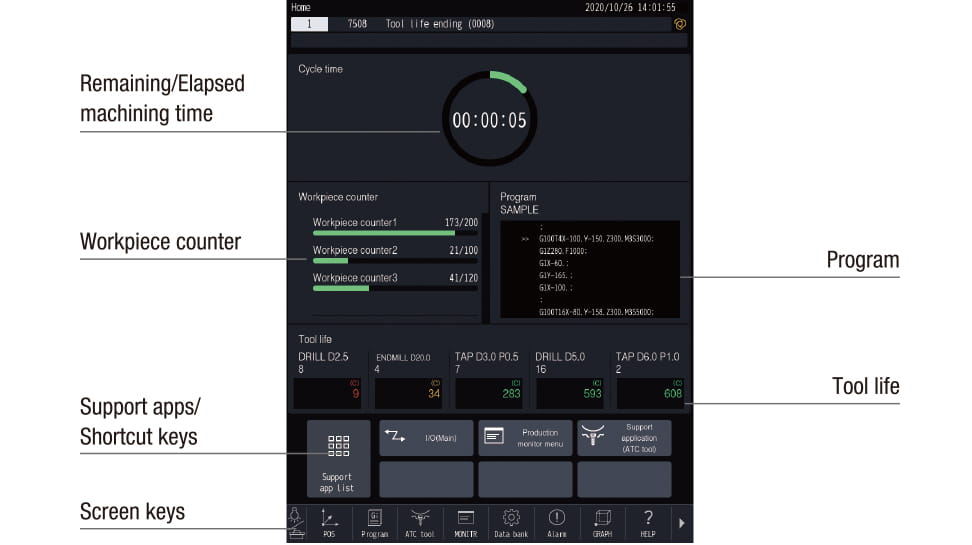

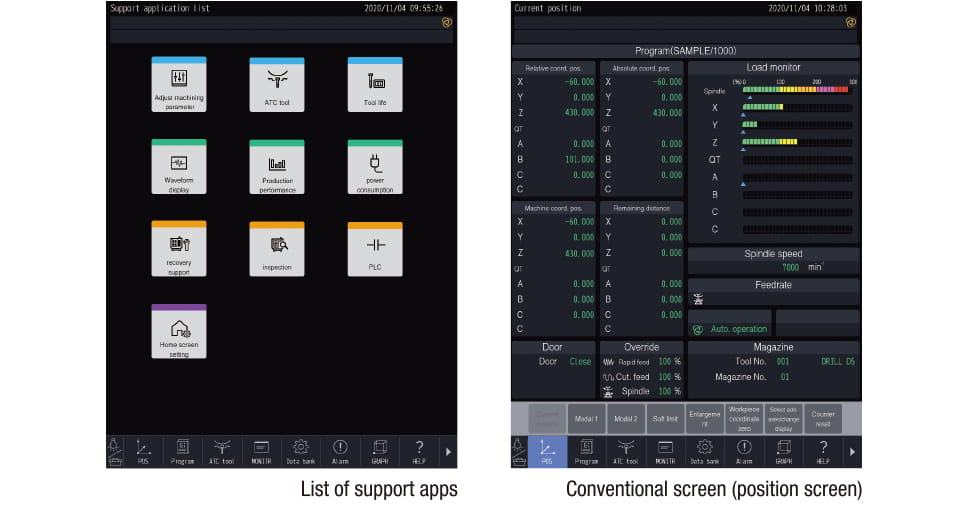

| Display | 15-inch color LCD touch display | |

| Memory capacity | 500 Mbytes, 3 Gbytes (optional) (Total capacity of program and data bank) | |

| External communication | USB memory interface, Ethernet, RS232C (optional) | |

| No.of registrable programs | 4,000 (Total capacity of program and data bank) | |

| Program format | NC language, conversation (changed by parameter) Conversation from conversation program to NC language program available |

|

- * Number of "control axes" and/or "simultaneously controlled axes" are the maximum number of axes, which will differ depending on the destination country and the machine specifications.

- * Ethernet is a trademark or registered trademark of XEROX in the United States.

| Operation | Dry run Machine lock Program restart Rapid traverse override Cutting feed override Background editing Screen shot Operation level External input signal key

|

|---|---|

| Programming | Absolute / Incremental Inch / Metric Coordinate system setting Corner C / Corner R Rotational transformation Synchronized tap Subprogram Graphic display |

| Measurement | Automatic workpiece measurement *1 Tool length measurement |

| High speed and high accuracy | Machining parameter adjustment High-accuracy mode AIII High-accuracy mode BI (look-ahead 160 blocks) Backlash compensation

|

| Monitoring | Machining load monitoring ATC monitoring Overload prediction Waveform display / Waveform output to memory card Heat expansion compensation system ll (X, Y, and Z axes) Production performance display Tool life / Spare tool |

| Maintenance | Tap return function Status log Alarm log Operation log Motor insulation resistance measurement Tool washing filter with filter clogging detection Breake load test |

| Automatic / Network | Computer remote OPC UA Auto notification Built-in PLC (LD/ST/FBD)

|

| Energy saving | Automatic power off Standby mode Automatic coolant off Automatic work light off Chip shower off delay |

| Support apps | Adjust machine parameters ATC tool Tool life Waveform display Production performance Power consumption Recovery support Inspection PLC |

| Accessories | File viewer Notebook Calculator Register shortcut Display off |

| Functions limited to NC language | Menu programming Local coordinate system Expanded workpiece coordinate system One-way positioning Inverse time feed Programmable data input Tool length compensation Cutter compensation Scaling Mirror image External sub program call Macro Operation in tape mode Multiple skip function

|

| Functions limited to conversation | Operation program Schedule program Automatic tool selection Automatic cutting condition setting Automatic tool length compensation setting Automatic cutter compensation setting Automatic calculation of unknown number input Machining order control |

- *1 Measuring instrument needs to be prepared by users.

- *2 When the submicron command is used, changing to the conversation program is disabled.

- *3 There are restrictions on the axis configuration.

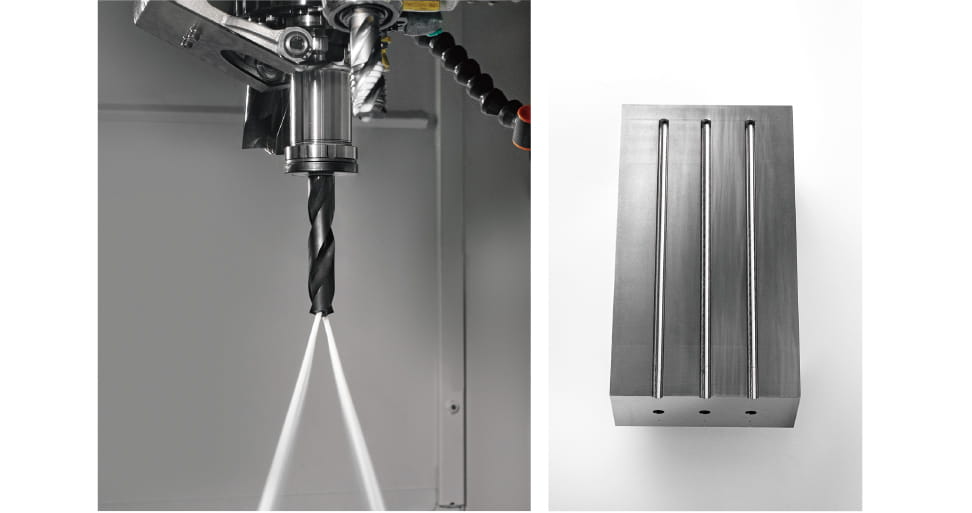

Example

Brass

Stainless steel

Stainless steel

Brass

Aluminum alloy

Aluminum alloy

Cast iron

![[New indow]](-/media/2BBAEB19B7CF43A5A42B2C3A137A3E81.ashx)