SPEEDIO R650X2

Pallet Changing Compact Machining Center

- Travels (mm): X: 650 Y: 400 Z: 305

- Max. spindle speed (min-1): 10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

- Tool storage capacity(pcs.): 14/ 22

Select variant: R650X2 40tools

Equipped with SPEEDIO's Largest Tool Magazine! Large Jig Mountable Pallet Changer Machine

Information

Overview

QT table

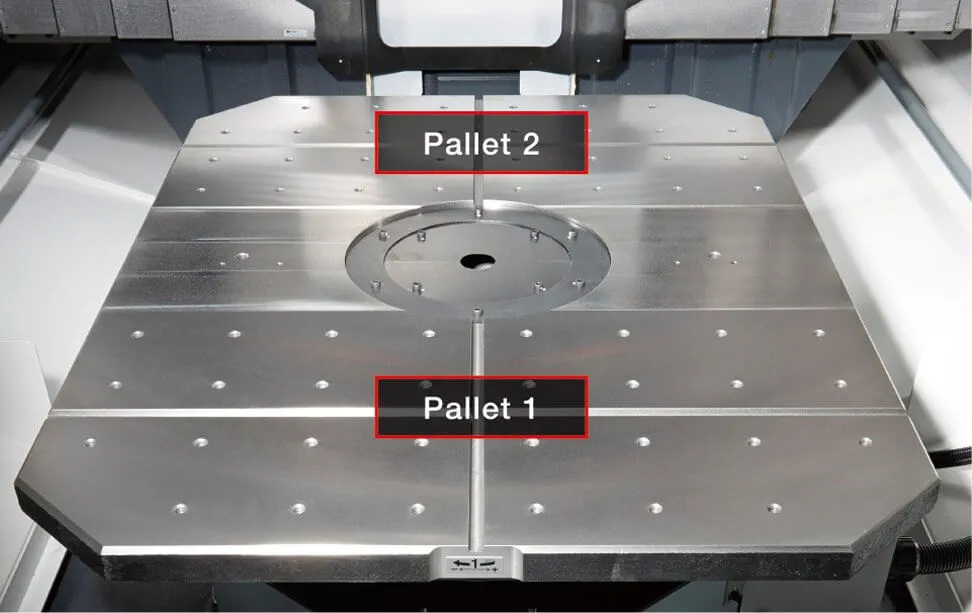

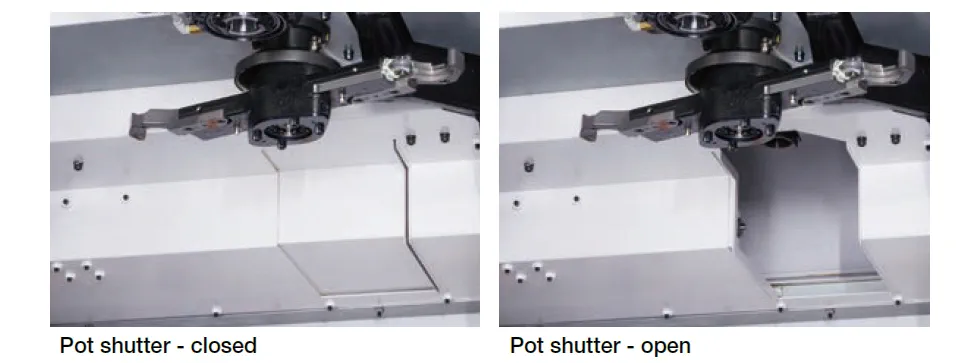

The QT (Quick Turn) table is Brother's original turn table type high-speed 2-face pallet changer. High-speed pallet change is enabled by avoiding lift-up operation while achieving high reliability through a sealed structure. Workpieces on one pallet can be changed while machining workpieces on the other pallet. Therefore, waste in workpiece change time is eliminated, enabling nonstop machining.

Pallet change time

3.4s

Machining area

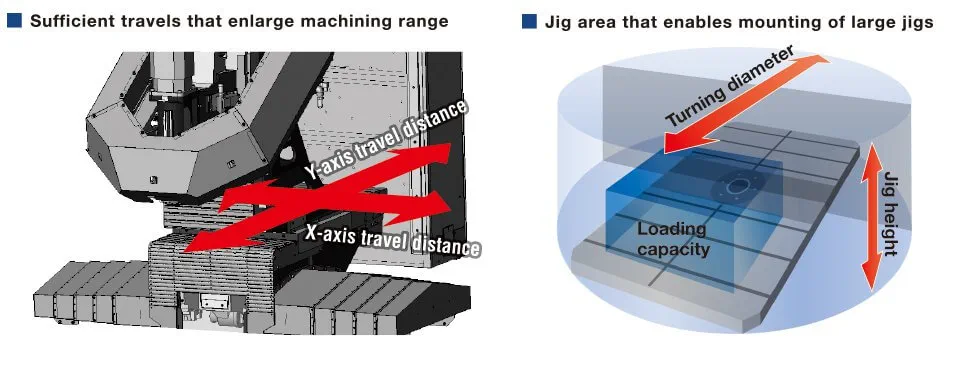

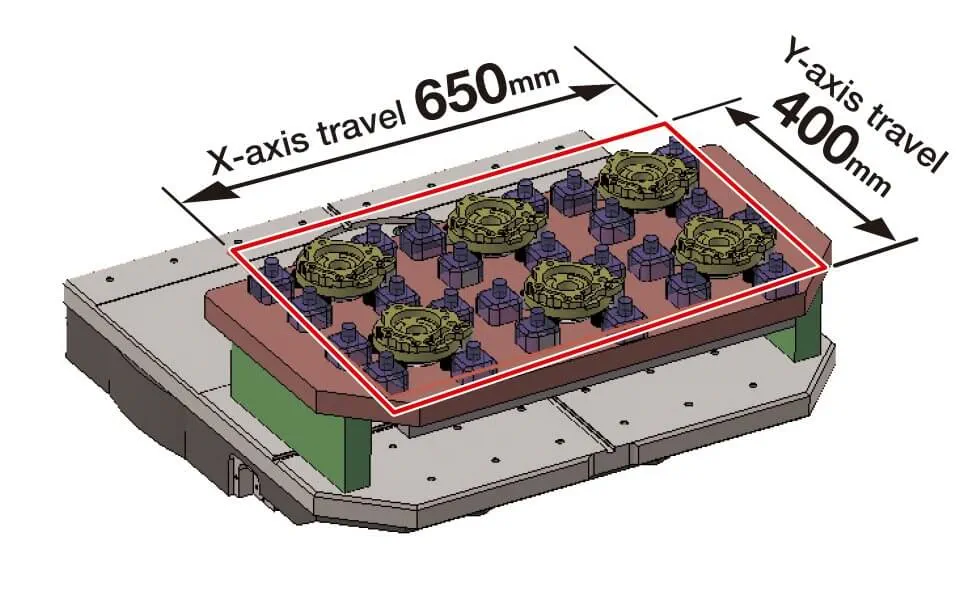

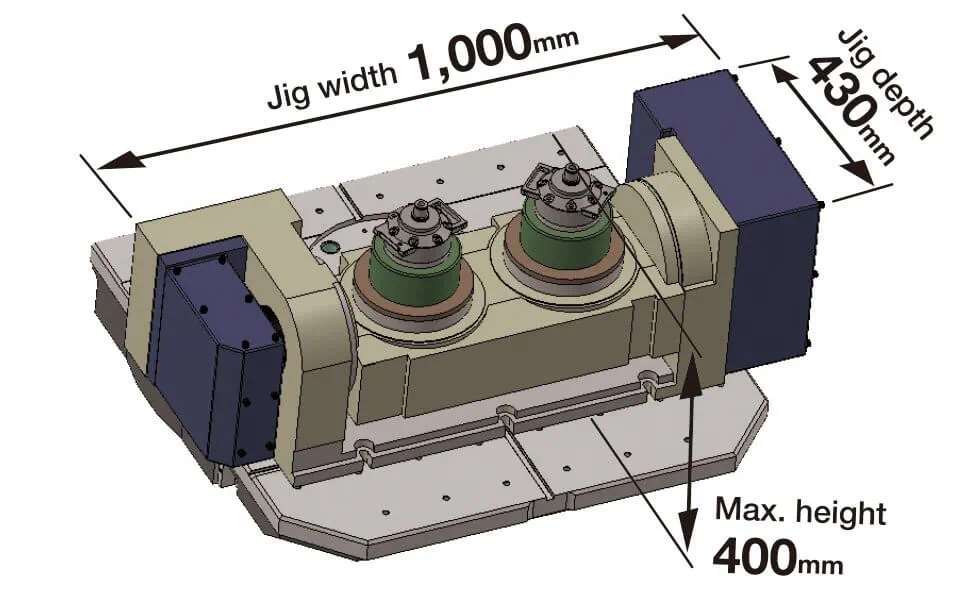

Making use of Brother’s original pallet changer technologies, the machine provides sufficient travels and a large jig area, which are not available on conventional #30 machines standard equipped with a pallet changer.

X-axis travel distance : 650mm

Y-axis travel distance : 400mm

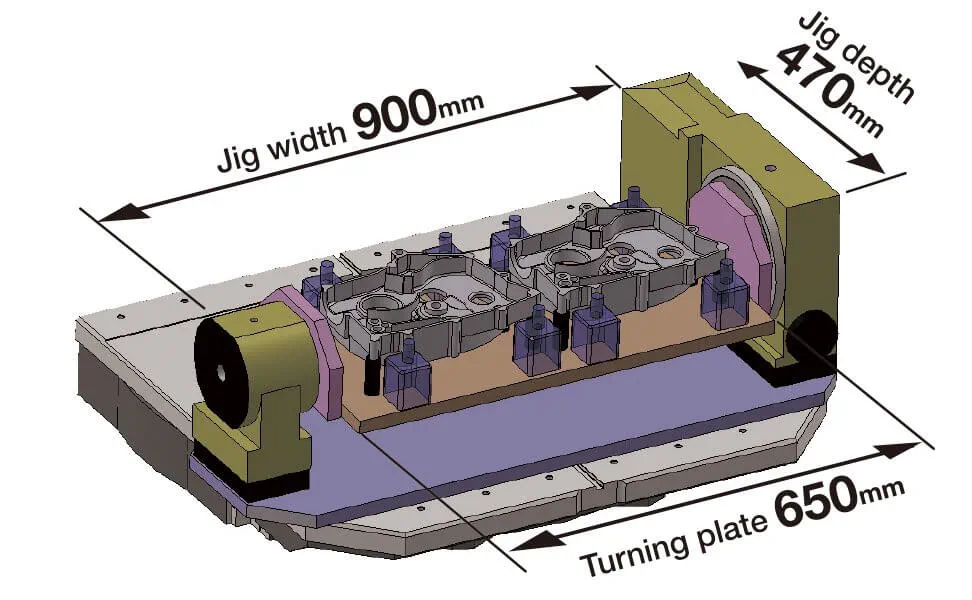

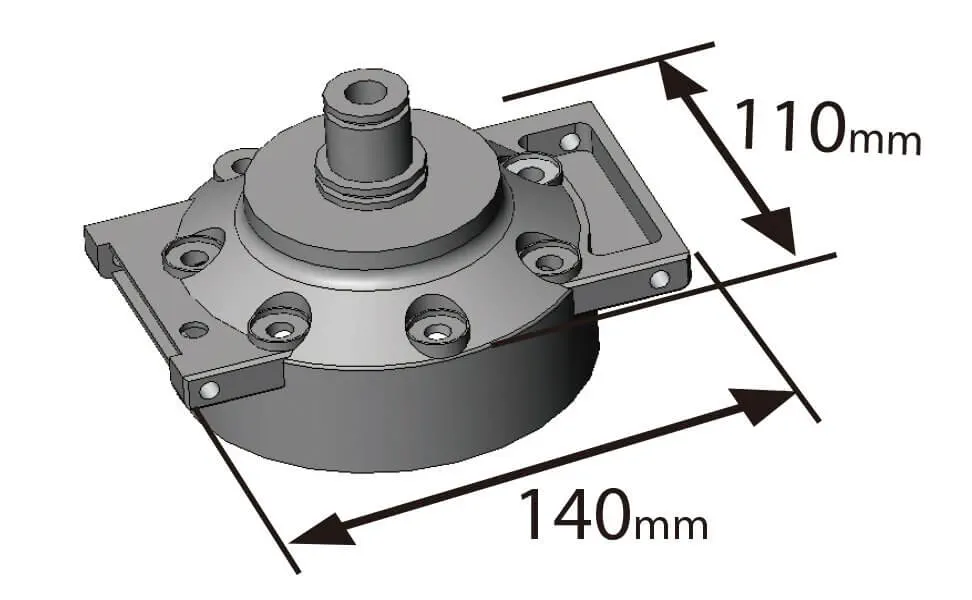

The turning diameter and the table size have been increased, enabling the mounting of large jigs. In particular, this makes mounting a trunnion jig using a rotary table easier.

Turning diameter : 1,250mm (max. 1,300 mm)

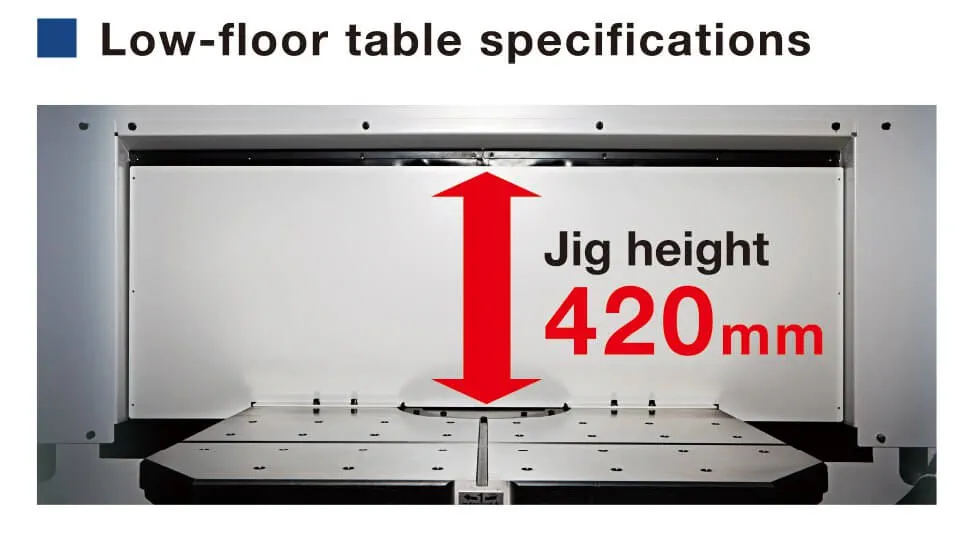

Jig height : 350mm (low table: 420 mm)

Leading capacity(one face) : 200kg (max. 300 kg)

Work area size(one face) : 800x400mm

Expandability

To enable the mounting of much larger jigs, two options are available: a low-floor table option that increases the jig height and a turning diameter enlargement option that increases the turning diameter to 1,300 mm. The loading capacity can also be increased to 300 kg (one face).

*: The parameter must be changed.

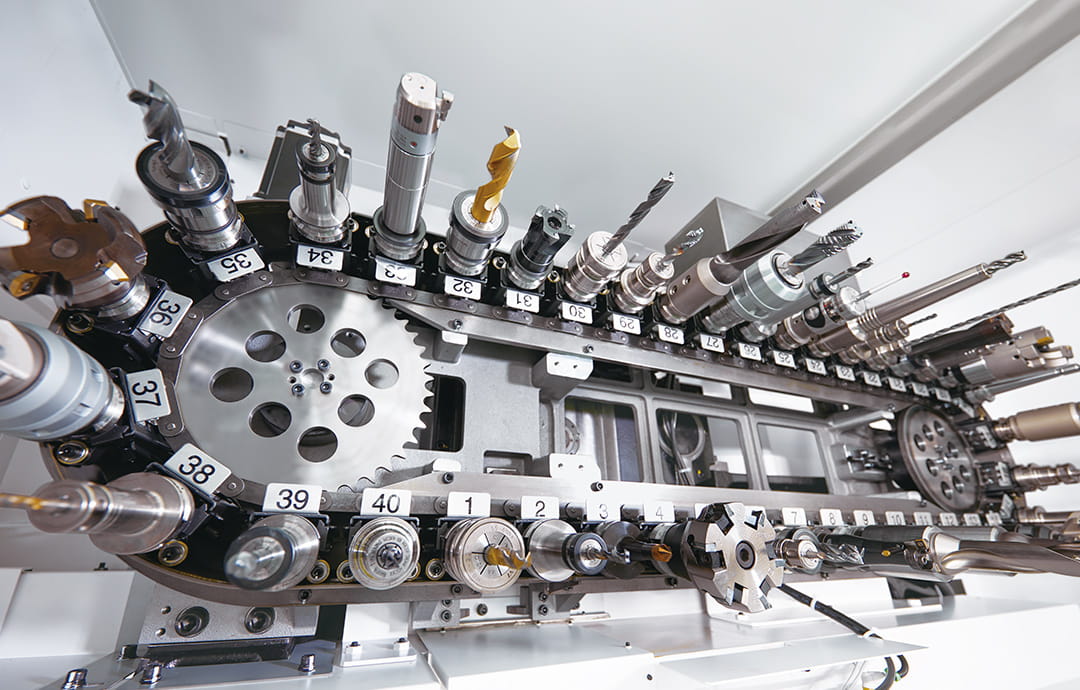

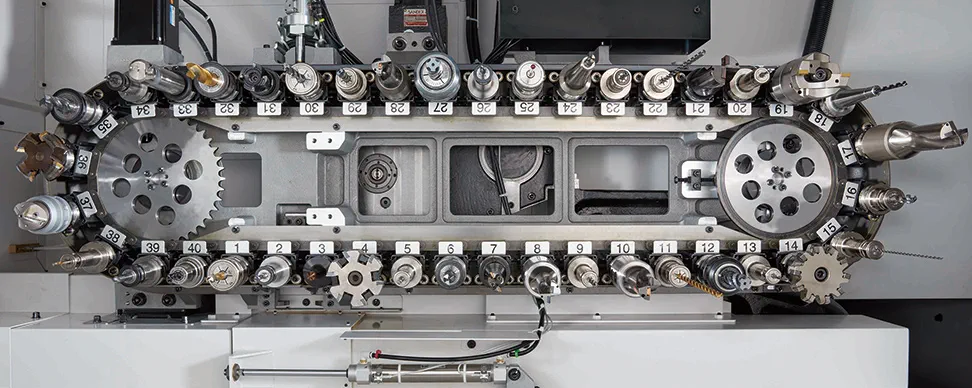

40-tool storage capacity

R650X2 can select tool storage capacity 14 pcs, 22 pcs and 40 pcs. This model is suitable to improve the productivity by process integration with a pallet changer.

Productivity

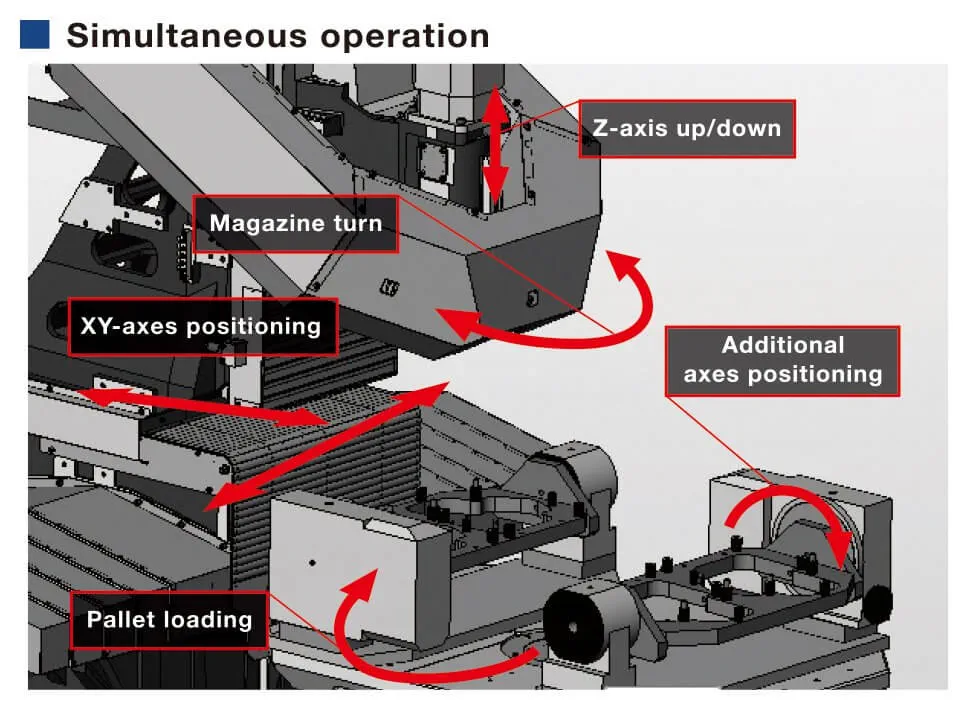

Enhanced speed and acceleration, and optimal control with any waste operation and time eliminated, drive machine performance to the fullest, demonstrating high productivity.

Spindle start/stop time

0.15s

High-speed tool change is achieved by increasing the speed of, and optimizing the control for, spindle start/stop, Z-axis up/down, and magazine operation.

Tool change time

40-tool / 22-tool / 14-tool

Tool - Tool : 0.9s / 0.8s / 0.7s

Chip - Chip : 2.6s / 1.6s / 1.4s

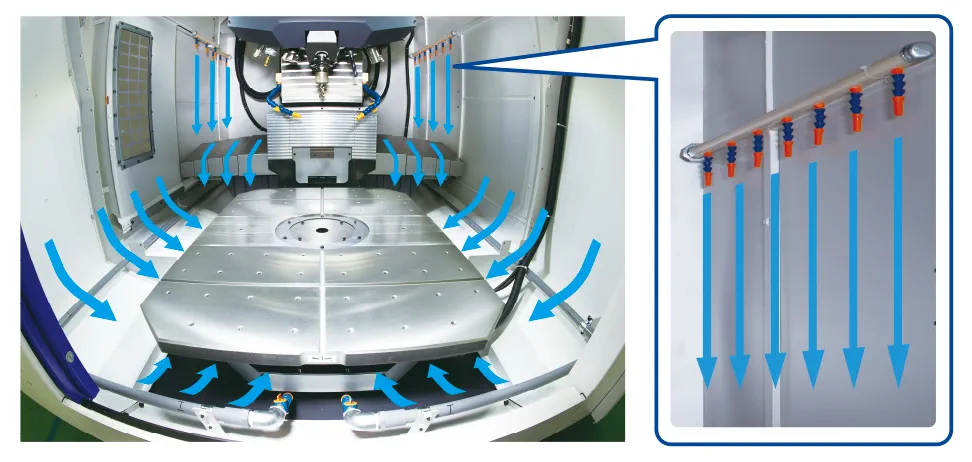

Reliability

High reliability is achieved by improving chip discharge performance and enhancing maintenance functions, contributing to the improvement of the machine's operating rate.

Specifications

Product Specification

R650X2

Max. spindle speed

10,000/ (Optional) 16,000/ (Optional) 10,000 high-torque

Travels

X: 650 Y: 400 Z: 305

Tool storage capacity

14/ 22

Rapid traverse rate (XYZ-area)

50 x 50 x 50

Required Floor Space

1,897 x 3,448

BT dual contact spindle(BIG-PLUS)

Optional

Coolant Through Spindle(CTS)

Optional

Low floor table

Optional

| R650X2*10 | 14/22 tool | 40-tool | ||

|---|---|---|---|---|

| CNC Unit | CNC-C00 | |||

| Travels | X axis [mm (inch)] | 650 (25.6) | ||

| Y axis [mm (inch)] | 400 (15.7) | |||

| Z axis [mm (inch)] | 305 (12.0) | 435 (17.1) | ||

| Distance between table top and spindle nose end [mm (inch)] | 250 - 555 (9.8 - 21.8) [320 - 625 (12.6 - 24.6)]*7 | 250 - 685 (9.8 - 27.0) [320 - 755 (12.6 - 29.7)]*7 | ||

| Table | Work area size [mm (inch)] | One face 800 x 400 (31.5 x 15.7) | ||

| Max.loading capacity (uniform load) [kg (lbs)] | One face 200 (441) [300 (661)]*6 | |||

| Spindle | Spindle speed [min--1] | 10,000min-1specifications:10 - 10,000

16,000min-1specifications:16 - 16,000 10,000min-1high-torque specifications(optional):10 - 10,000 |

||

| Speed during tapping [min--1] | MAX. 6,000 | |||

| Tapered hole | 7/24 tapered No.30 | |||

| BT dual contact system (BIG-PLUS) | Optional | |||

| Coolant Through Spindle (CTS) | Optional | |||

| Feed rate | Rapid traverse rate (XYZ-area)

[m/min (inch/min)] |

50 x 50 x 50 (1,969 x 1,969 x 1,969) | ||

| Cutting feed rate [mm/min (inch/min)] | X,Y,Z axis : 1 - 30,000(0.04 - 1,181)*8 | |||

| ATC unit | Tool shank type | MAS-BT30 | ||

| Pull stud type*4 | MAS.P30T-2 | |||

| Tool storage capacity [pcs.] | 14 / 22 | 40 | ||

| Max. tool length [mm (inch)] | 200 (7.9) | 250 (9.8) | ||

| Max. tool diameter [mm (inch)] | 80 (3.1) | 55 (2.1) / 125 (4.9) No adjacent tool | ||

| Max. tool weight *1 [kg (lbs)] | 3.0(6.6) [total tool weight : 25(55.1) for 14 tools, 40(88.2) for 22 tools] | 4.0(8.8) [total tool weight : 80(176.3)] | ||

| Tool selection method | Random shortcut method | Double arm method (random closest path) | ||

| Tool change time*5 | Tool To Tool [sec.] | 0.7/0.8 (14 tool/22 tool) | 0.9 | |

| Chip To Chip [sec.] | 1.4/1.6 (14 tool/22 tool) | 2.6 | ||

| Electric motor | Main spindle motor (10 min/continuous) *2 [kW] |

10,000min-1specifications:10.1/7.0 16,000min-1specifications:7.4/5.1 10,000min-1high-torque specifications:12.8/9.2 |

||

| Axis feed motor [kW] | 1.0 (X,Y), 1.8 (Z) | |||

| Power source | Power supply | AC200V ±10%, 50/60Hz ±1Hz | ||

| Power capacity (continuous) [kVA] | 10,000min-1 specifications : 9.5 16,000min-1 specifications : 9.5 10,000min-1 high-torque specifications : 10.4 |

|||

| Air supply | Regular air pressure [MPa] | 0.4 - 0.6 (recommended value : 0.5MPa) *9 | ||

| Required flow [L/min] | 50 | 100 | ||

| Machine dimensions | 機Height [mm (inch)] | 2,696 (106.1) | ||

| Required floor space (with control unit door open) [mm (inch)] | 1,897 x 3,448 [3,868] (74.7 x 135.7 [152.3]) | 2,145 x 3,248 [3,868] (84.4 x 127.9 [152.3]) | ||

| Weight [kg (lbs)] | 3,500 (7,716) | 4,000 (8,818) | ||

| Accuracy*3 | Accuracy of bidirectional axis positioning (ISO230-2:2006) [mm (inch)] | 0.006 - 0.020 (0.00024 - 0.00079) | ||

| Repeatability of bidirectional axis positioning (ISO230-2:2006) [mm (inch)] | Less than 0.004 (0.00016) | |||

| Standard accessories | Instructin manual (1 set), Anchor bolts (5 pcs.), Leveling bolts (5 pcs.) | |||

- *1 Maximum tool weight differs depending on the configuration and center of gravity. The figures shown here are for reference only.

- *2 Spindle motor output differs depending on the spindle speed.

- *3 Measured in compliance with ISO standards and Brother standards. Please contact Brother for details.

- *4 Brother specifications apply to the pull studs for CTS.

- *5 Measured in compliance with JIS B6336-9 and MAS011-1987.

- *6 Can be increased up to 300kg (one face) by changing the parameter. Please consult us separately.

- *7 Values when the low-floor table is selected.

- *8 When using high accuracy mode B. When not using high accuracy mode B, 1 to 10,000 mm/min for X/Y-axes and 1 to 20,000 mm/min for Z-axis.

- *9 Regular air pressure varies depending on the machine specifications, machining program details, or use of peripheral equipment. Set the pressure higher than the recommended value.

- *10 The machine needs yo be equipped with a relocation detectiondepending on the destination.Machine equipped with a relocation detection device come with “RD”at the end the model name.

| Type | 0 deg./180 deg. turntable system |

|---|---|

| Table dimension [mm (inch)] | 800 x 535 (31.5 x 21.1) (one face) |

| Max. turning diameter [mm (inch)] | D1,250 (49.2) [D1,300 (51.2)]*1 |

| Max. jig height [mm (inch)] | 350 (13.8) [420 (16.5)]*2 |

| Table work area size [mm (inch)] | 800 x 400 (31.5 x 15.7 ) (one face) |

| Max. loading capacity [kg (lds)] | 200 (441) [300 (661)] (one face)*3 |

| Rated table load inertia for turning axis [kg·m2] | 35.8 [53.7](one face)*3 |

| Table turning system | AC servo motor (0.82kW) Worm gear (total speed reduction ratio:1/60) |

| Table position time | 3.4s*4 |

| Table change repeatability [mm (inch)] | 0.01 (0.0004) (in the X,Y, and Z axes directions 335 (13.2) from the center of rotation) |

- *1 When the turning diameter enlargement option is selected.

- *2 Values when the low-floor table is selected.

- *3 Can be increased up to 200kg (one face) by changing the parameter. Please consult us separately.

- *4 When the loading capacity is 200 kg (one face)

- ※ Quick turn table is a turntable type 2-face pallet changer

| CNC model | CNC-C00 | |

|---|---|---|

| Control axes | 7 axes (X,Y,Z,4 additional axes) | |

| Simultaneously controlled axes | Positioning | 5 axes (X, Y, Z, A, B) |

| Interpolation |

|

|

| Least input increment | 0.001mm, 0.0001inch, 0.001 deg. | |

| Max.programmable dimension | ±9999.999mm ±999.9999inch | |

| Display | 12.1-inch color LCD | |

| Memory capacity | Approx.100 Mbytes (Total capacity of program and data bank) | |

| External communication | USB memory interface, Ethernet, RS232C | |

| No.of registrable programs | 4,000 (Total capacity of program and data bank) | |

| Program format | NC language, conversation (changed by parameter) conversion from conversation program to NC language program available |

|

| NC function |

|

|

| Optional NC functions |

|

|

- *1 Measuring instrument needs to be prepared by users.

- *2 When the submicron command is used, changing to the conversation program is disabled.

- *3 Minute block processing time can be changed.

- *: Number of "control axes" and/or "simultaneously controlled axes" are the maximum number of axes, which will differ depending on the destination country and the machine specifications.

- *: Ethernet is a trademark or registered trademark of XEROX in the United States.

- *: Functions listed under (NC) and (Conversation) are available only for NC programs and conversation programs respectively.

For options, please contact us.

Example

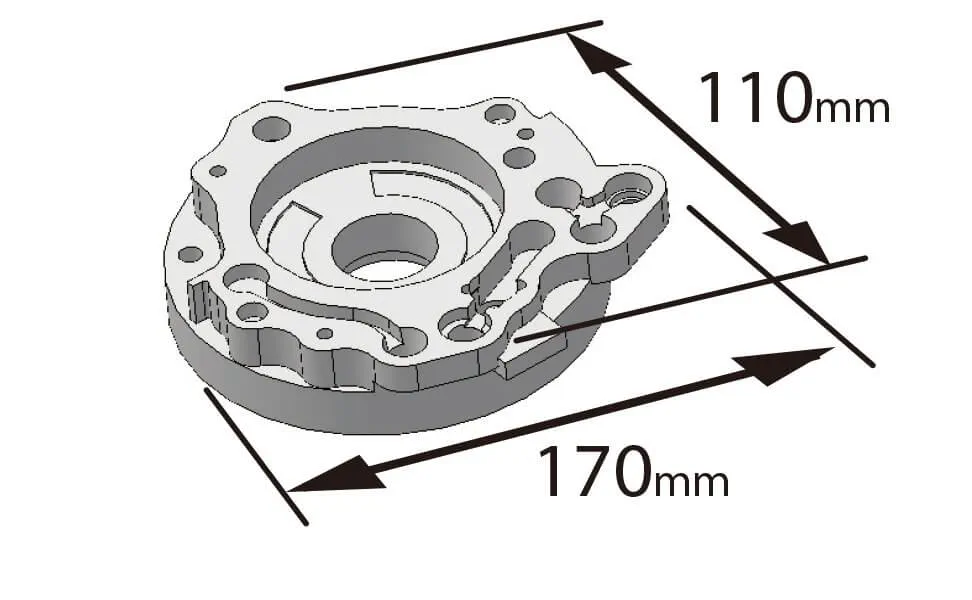

Example1 Multiple parts machining

Workpiece nameOil pump body (automobile)

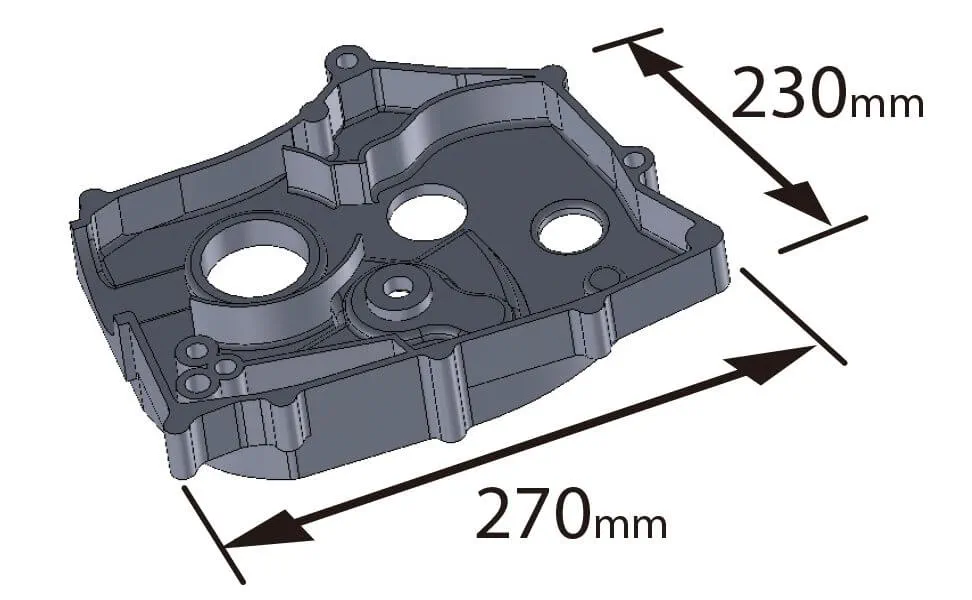

Example2 Trunnion jig

Workpiece nameCrank case (motorbike)

Example3 Tilting two-spindle rotary table

Workpiece nameCompressor housing (automobile)

Support

Reviews

Suitable with

Machine Tools Lineup

Compact machining center SPEEDIO

Horizontal Compact Machining Center

Multi-Tasking Machine SPEEDIO