Semiconductor Production Epuipment Parts Machining Solutions

Japanese manufacturers account for more than 30% of the global market for semiconductor production equipment used to manufacture semiconductors, and demand is also expanding in Taiwan, South Korea, and China.

SPEEDIO is a #30 machining center suitable for aluminum processing of semiconductor production equipment parts, multi-tasking machine, and process integration.

・Energy saving performance achieved by optimal design

・Compactness, space saving, and superior cost effectiveness

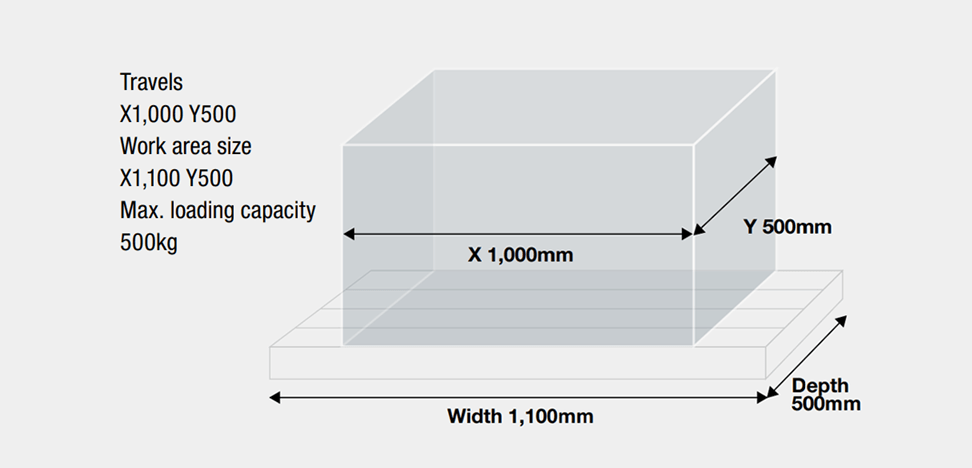

Ample travels and table size (W1000Xd2)

The travel of 1000 x 500 mm and the maximum loading capacity of 400kg allows large workpieces or multiple jigs to be mounted, which was not available on the conventional #30 machining center.

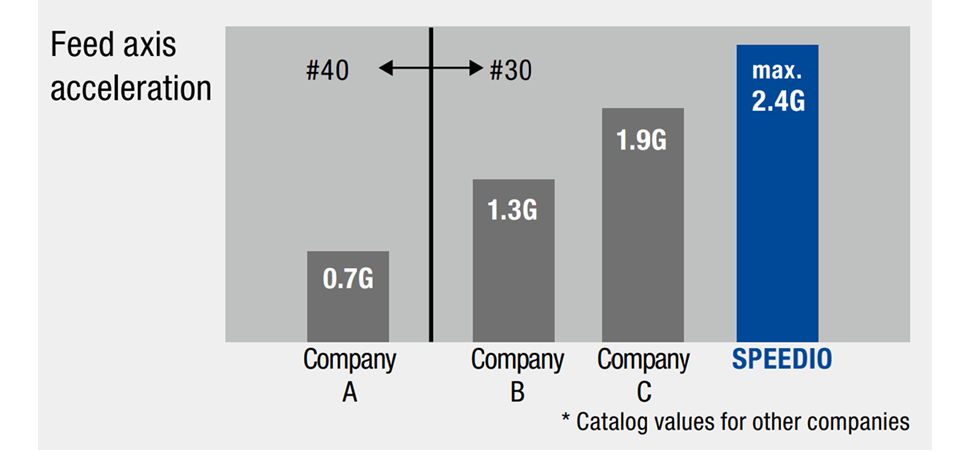

Max. 2.4G Z-axis acceleration (W1000Xd2)

With a highly efficient motor and optimized motor control, the machine demonstrates top-class high-speed performance in peck-drilling small holes..

*Peck drilling is a machining method that forcibly divides chips while feeding in steps. The non-cutting time is long due to many steps during machining. W1000Xd1 can reduces the cycle time by Z-axis higher acceleration.

Semiconductor Production Epuipment Parts and Features of SPEEDIO

Parts |

SCompact Machining Center

|

W Wide Travel Compact Machining Center

|

U Universal Compact Machining Center

|

R Pallet Changing Compact Machining Center

|

F High Rigidity

|

M Compact Multi-tasking Machining

|

||||

|---|---|---|---|---|---|---|---|---|---|---|

| S300Xd1 | S500Xd1 | S700Xd1 | W1000Xd2 | U500Xd1 | R450Xd1 | R650Xd1 | F600X1 | M200Xd1 | M300Xd1 | |

Large-diameter plateAluminum alloy |

||||||||||

Aluminum caseAluminum alloy |

||||||||||

Transfer equipment partsAluminum alloy |

||||||||||

Transfer equipment partsAluminum alloy |

||||||||||

Transfer equipment partsAluminum alloy |

||||||||||

L-shaped bracketSUS316L |

||||||||||

PlateSUS316L |

||||||||||

Support BracketSUS316L |

||||||||||

Feeder FrameAluminum alloy |

||||||||||

IC test socketsAluminum alloy |

||||||||||

Parts

Machining Center

Large-diameter plate

Aluminum alloy

⌀600 x 30

Feeder Frame

Aluminum alloy

600 x 250 x 12

IC test sockets

Aluminum alloy

65 x 65 x 6