- Products

- Support & Download

- Solutions

- Contacts

- About Brother

Sawada Light Metal LTD

Using SPEEDIO's cost advantages to rapidly expand production capacity

Sawada Light Metal Co., Ltd. (Headquarters: Kasugai City, Aichi Prefecture)

Sawada Light Metal Co., Ltd. established in 1967

Mr. Ko Sawada, President and Representative Director

Sawada Light Metal Co., Ltd. (Hereafter the company) was established in 1967 and has been handling aluminum for three generations of the company. The company's business started with surface treatment (anodizing) of aluminum. To date, the company has expanded the scope of its business to include machining. The company's feature is its ability to perform integrated production from material procurement to high-accuracy machining and anodizing. Their main products are parts for semiconductor production line equipment, and they also produce parts for industrial air conditioning and housing equipment.

Over the past few years, the company has seen a significant increase in sales. President Sawada says, "One reason for this is the growth of our customers’ industries, but the installation of the SPEEDIO is definitely another good reason."

Continuous installation made possible by the SPEEDIO

Looking at the background of installation, President Sawada says, "We anticipated an increase in orders and felt the need to invest in equipment to enhance the production capacity." When considering machines, the SPEEDIO was in his sights early on from a cost viewpoint. However, he also says, "I was a little concerned about the machining capabilities." So, he visited the Brother booth at the exhibition, and consulted with the staff from Brother, describing their products and machining procedures. "As a result, I decided to install one to see how it went," he said, describing how he came to the decision of installation.

The first SPEEDIO was installed at their factory in November 2017. Since then, SPEEDIO machines have been added at a rate of almost two per year through to 2023.

"If the cost of one machine is too large, continuous installation is difficult. Minimizing the initial cost of installation is very significant for small and medium-sized companies like us. Thanks to the reasonable price of the SPEEDIO, we have been able to install machines smoothly, and our production capacity has increased dramatically."

SPEEDIO machines lined up in the factory

Over 10 SPEEDIO machines installed in 6 years

Ease of handling without causing stress is an advantage

As an additional advantage to the cost, President Sawada mentioned "ease of handling." Tools themselves are compact and everything is lightweight, including vises, so handling workpieces has become easier.

He says, "When you open the door, tools are right in front of you, so you can adjust and check them quickly. This means workers feel less stress. In the work process, to be hassle-free is more important than to be always conscious of speed. I believe that ease of handling makes workers more positive and proactive in their approach to their work." He also says, “As the workload has been reduced, working hours have been reduced accordingly."

In addition, he confirmed that there were no problems with the machining capabilities, which he had been concerned about. "Our work involves a lot of plate work, and it is based on general machining, such as drilling and tapping. There are not so many operations that require deep drilling or long hours of cutting. From this point of view, I think that the SPEEDIO is very well suited for our company."

Working scene using the SPEEDIO

Working scene using the SPEEDIO

The SPEEDIO plays an active role as powerful force, overcoming preconceptions

President Sawada says he had strong preconceptions about machines. “During the period of the previous president, we were handling many large workpieces, so we had preconceptions that only BT40 machines could cut large workpieces or BT50 machines would be the best for large workpieces. It is true that I was not confident about the capabilities of BT30 machines." Therefore, he was surprised at the difference from the image he had when he actually used the SPEEDIO.

He says he is also satisfied with Brother’s attentive support. “It might be Brother’s corporate culture, but people in charge are frank and easy to consult with. For example, even if I ask for something unreasonable, they are able to work out a mutually beneficial solution through discussions. I really appreciate that."

In addition, he comments that SPEEDIO's color and design are "cool," which also served as an additional deciding factor.

"There are many choices, but it is not good to spend large budgets that may result in overperformance, and vice versa. I think a good balance of cost, performance, and quality is important. The SPEEDIO is a perfect match for our company."

Looking to the future, President Sawada says, "As various things are subdivided and competition is becoming increasingly intense, we want to make the most of our strengths and move forward steadily."

As a partner, Brother will continue to provide positive support for their business from an equipment standpoint.

Interview scene

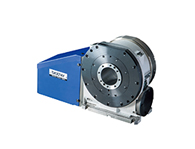

Products introduced

S700X2 / S500X2 / S300X2

The SPEEDIO maximizes productive efficiency improvement of mass-production parts such as automobile, motorcycle and information technology.

W1000Xd1

"Machining larger workpieces using #30 machine" The release of the W1000Xd1 machining center sees an override in the conventional machining areas of #30 machines.

Equipped with new NC controller

Customer considering purchase

-

Catalog download

Guide of Compact machining center SPEEDIO catalog download.

-

Contacts-ProductInformation (Asia & Oceania)

Contact for product information, development, or usage, and regional sales offices.

-

Contacts-ProductInformation (Europe Distributors)

Contact for product information, development, or usage.