High-Quality, High-Efficiency, and Short-Delivery-Time Production of High-Mix, Small-Lot Products

Upon entering the Taiyo factories, you will see an impressive row of Brother tapping centers and machining centers. The main factory currently operates 53 machines, and the Kumamoto Factory operates 23, providing support for high-speed machining operations.

The company first adopted the Brother "TC-211" tapping center in July 1985. This was the first commercially produced machine in this series.

Chairman Ryoji Miyaji explained that the company attended an exhibition for distributors held at the Brother Mizuho Factory along with machinery tool trading company Sanga Corporation, based in Hamamatsu and led by President Sugiura. The chairman decided to adopt the TC-211 on the spot. At a time when workers at the Taiyo factories machined using lathes, milling machines, drill presses, and other equipment, the chairman was captivated by the high-speed drilling and tapping capabilities of the Brother tapping center. As the company's workpieces were mainly aluminum castings, it was decided to adopt the Brother machine because it provided an ideal means for light cutting and high-speed machining.

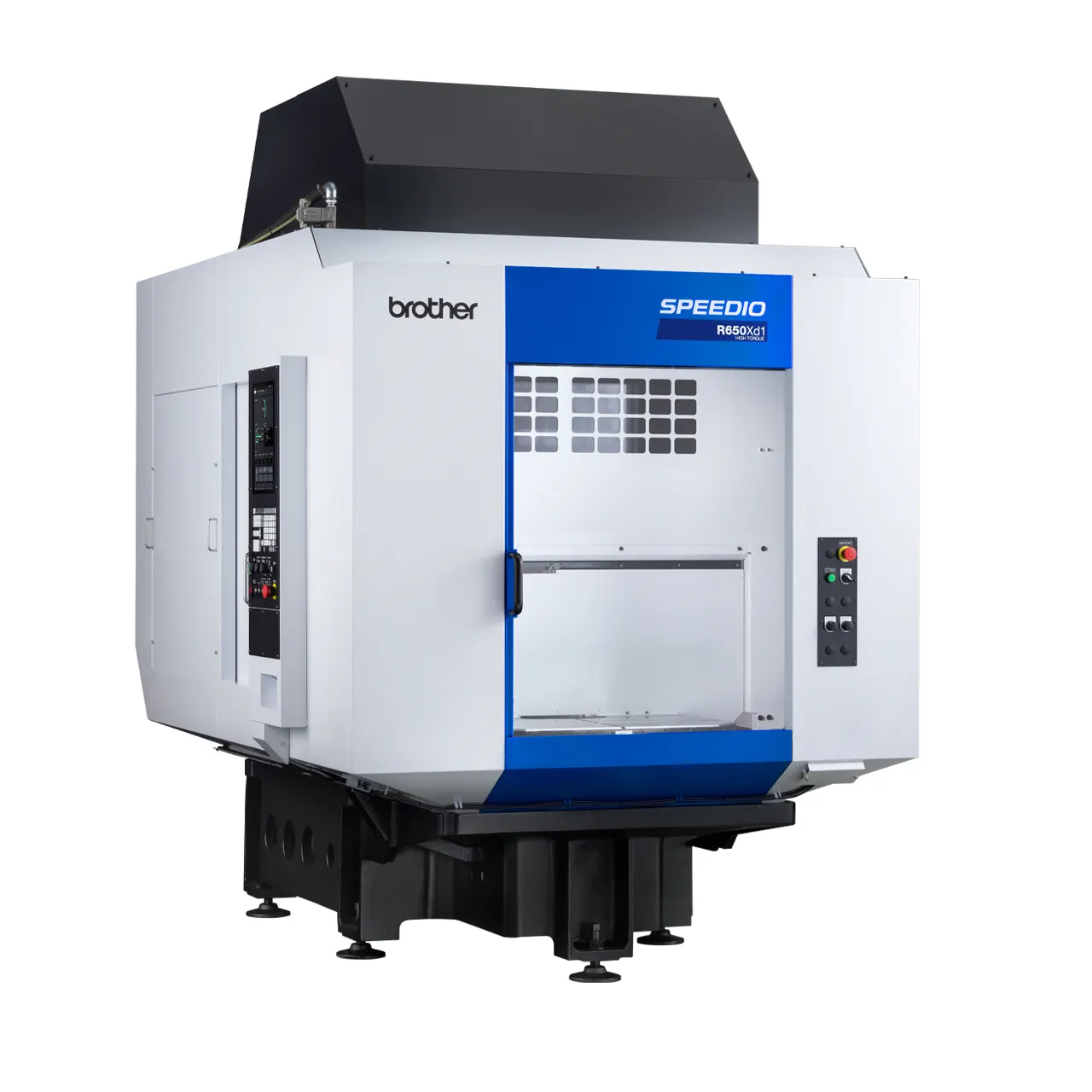

Later, the company also installed an NC machine and BT40 machining center, improving productivity, and in an effort to appeal to end users by mastering the BT30, speeding up machining, and reducing costs, the company continued its switch to Brother machines. Today, the main factory operates 53 units. President Nobuharu Miyaji recalled that when he first started working at Taiyo 12 years ago, there were eight BT40 machines, which were gradually replaced with BT30 units, with the last BT40 being swapped out for a BT30 (Brother SPEEDIO) just the other day.

This year, Taiyo introduced a system that connects two NC lathes and a machining center with an autonomous robot to realize unmanned machining.

President Nobuharu Miyaji enthusiastically described the new system. "We have received more orders for automotive parts over the past 10 years. For large orders, we have taken on the challenge of efficiently machining these using a system that combines a robot, multifunction machine, and machining center. Our company operates on a single-shift system, but with the adoption of the robot system, we have achieved the equivalent of 1.5 shifts. We look forward to expanding this system in the future."

Featured Products

S700X1

These machines contribute to maximizing the production efficiency for the machining of a wide range of mass-produced parts, including for automobile, motorcycles, and IT-related equipment.