[Machine Tool Basics] What Is NC Machining? The Advantages and Disadvantages of NC Machine Tools

![[Machine Tool Basics] What Is NC Machining? The Advantages and Disadvantages of NC Machine Tools](https://machinetool.global.brother/-/media/ap2/mt/speedio-navi/img/articles/a0038-01.jpg?h=534&iar=0&w=1600&rev=c405273798df4002b448978121cd0841)

In recent years, machining methods using numerical control (NC) have become indispensable in manufacturing sites. NC machining improves productivity and quality, with the types and performance of NC machine tools continuing to evolve day by day.

This article introduces “Basic Knowledge of NC Machining” for all those involved in the manufacturing industry. We will also cover the advantages of NC machines, points to note when introducing them, and the future prospects of NC machining.

What Is NC Machining?

NC machining is a machining method in which the machine tool is controlled with a computer to perform cutting, and a machine tool capable of NC machining is called an NC machine tool. NC stands for “numerical control.” The program used for NC machining is called an NC machining program. These programs provide instructions for the machine tool movement and cutting conditions and execute workpiece machining. Being program-based, the major advantage of NC machining is the ability to machine parts with complex geometry and designs consistently with high accuracy.

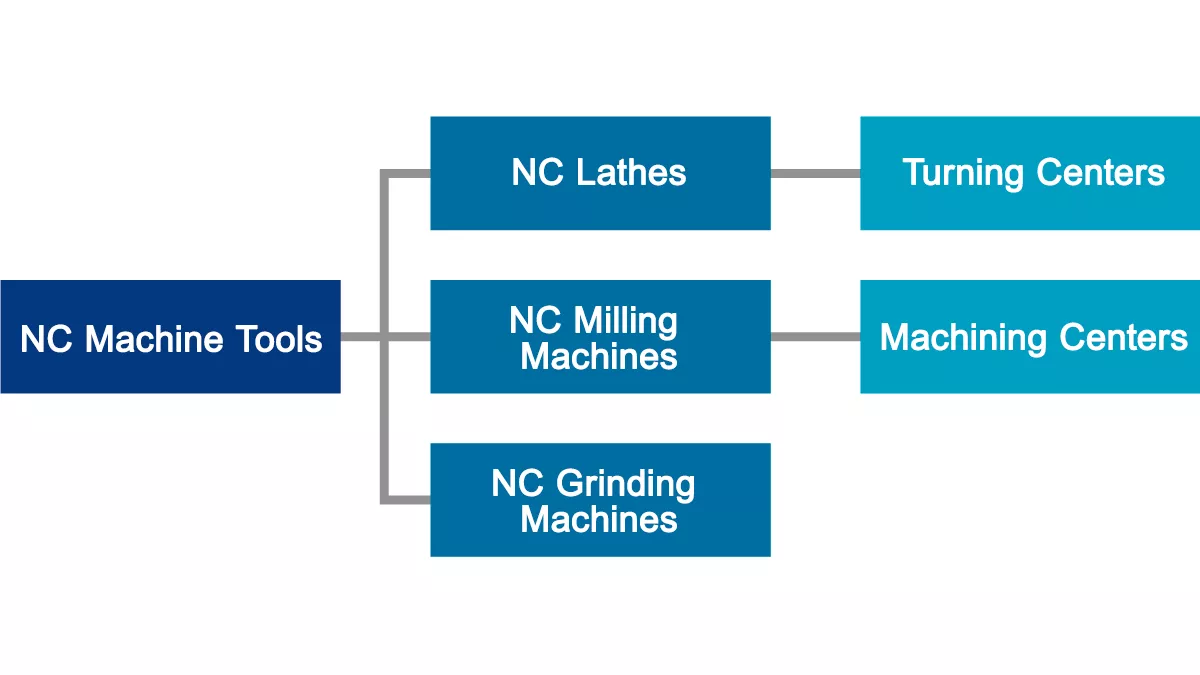

“NC machine tool” is a collective term for any machine tool that performs computer-controlled machining. There are several types of NC machine tools, including NC lathes, NC milling machines, and machining centers.

What Are NC Machine Tools?

There are various types of NC machine tools. Let's take a look at the different types of NC machine tools and their characteristics.

CNC Machine Tools vs. NC Machine Tools

Bottom line, it is safe to assume that the term computer numerical control (CNC) machine tool is nearly synonymous with NC machine tool. While originally referring to different machine tools, as machine tool technology has developed, they have come to be regarded as the same.

Early NC machine tools used to read programs recorded on punch tapes to control the machine. As the technology advanced, punch tapes were displaced by computers, and machine tools with an onboard computer came to be called CNC machine tools. The advent of CNC technology made more advanced and flexible machining possible, eventually evolving into the machining centers and multi-tasking machines so widely used today.

With computer control now so commonplace, both NC machines and CNC machine tools use computers, and it is no longer necessary to distinguish between the two.

NC Machine Tools vs. Machining Centers

A machining center (MC) is an advanced machine that is classified as a type of NC machine tool. Machining centers come equipped with an automatic tool changer, or ATC. Machining centers have multiple tools built in, enabling the machine tool itself to change through the cutting tools automatically while progressing through multiple machining processes.

As the machining center is essentially a more advanced milling machine, it performs cutting by pressing a rotating tool into the workpiece. A computer-controlled milling machine is called an NC milling machine, with the difference between that and a machining center being whether the machine has an ATC as described above.

For more on machining centers, see this article:

"What Is a Machining Center? The Basics on Structure, Types, Benefits, etc."

Types of NC Machine Tools

NC machine tool is a collective term for machine tools that operate using numerical control technology. This technology makes it possible to produce parts of complex geometry consistency and with high accuracy. The main types of NC machine tools and their characteristics are introduced below.

NC Lathes

A lathe is a machine tool used for a process called turning, in which a workpiece is mounted to the machine and rotated at high speed, with a tool pressed onto it. In the past, with universal lathes (normal lathes), the machinist would manually turn the handle to machine the workpiece. Now, NC lathes come with NC machining functionality.

NC Milling Machines

Unlike a lathe, cutting with a milling machine is performed by rotating the tool itself at high speed and bringing it in contact with the workpiece. Similar to the lathe, however, a universal milling machine given NC machining functionality is called an NC milling machine. An NC lathe works by rotating the workpiece, so it is used like a potter’s wheel, whittling pieces down into cylindrical or circular shapes. Meanwhile, in an NC milling machine, the tool is what is rotated. In this machine, the tool is pressed into the area to be cut, like carving a sculpture, allowing for machining to any shape.

Machining Centers

A machining center is an NC machine tool made by equipping an NC milling machine with an automatic tool changer (ATC). It is more multi-functional than an NC milling lathe, which greatly reduces the time spent handling and setting up the part. There are also machining centers capable of 5-axis machining, in which the tool spindle and table can be rotated and revolved.

Turning Centers

A turning center is a machine tool that can perform a wide variety of machining operations in addition to its basic function of turning, such as milling and drilling, on a single machine. In general, the turning center combines an NC lathe and a machining center. Sometimes, these are called multi-tasking machines. As they can perform multiple machining processes in a single pass on one machine, turning centers improve production efficiency and accuracy, and they allow for the flexibility to handle high-mix, low-volume production.

For more information, see this article:

"What Is a Multi-Tasking Machine? Advantages of Multi-Tasking Machines and How They Differ from Machining Centers Explained"

NC Grinding Machines

The NC grinding machine is a grinding machine operated with numerical control, and they are used primarily for grinding. While other machine tools listed above are also capable of grinding, NC grinding machines are particularly suited to machining parts requiring a high-accuracy finish. Using a grinding wheel, the workpiece surface is shaved down to perform detailed finishing or machine dimensions with high accuracy. There are various types of grinding machines depending on the purpose, such as surface grinding machines, cylindrical grinding machines, and internal grinding machines.

Advantages of Deployment

NC machine tools are already used in many factories and workshops. Here, we will explain in detail the specific advantages of deploying NC machine tools.

Enables High-Accuracy Machining

One of the greatest advantages of NC machine tools is their high machining accuracy. When the machining of particularly complex geometry, curves, and detailed sections is required, manual universal machine tools inevitably have their limitations. In this regard, NC machine tools use a computer to specify tool coordinates and rotational speed, allowing for even difficult machining to be performed to high accuracy.

Improves Work Efficiency and Productivity

With NC machine tools, once a machining program is created, the tool will perform the machining automatically. NC machine tools equipped with an ATC, such as a machining center or turning center, can reduce the time required to set up workpieces and cutting tools. More recently, there are now NC machine tools equipped with auto pallet changers capable of automatically removing workpieces. They shorten the time required to remove and change workpieces, enabling non-stop machining.

Stable Quality

Since NC machine tools follow their programming to operate, once the machining steps are configured, they perform the same motions with the same accuracy, every time. This reduces batch-by-batch variability and human error, allowing products to be produced at a stable quality.

Reduces Hazardous Work for Improved Safety

Conventional manual machining requires the operator to work in close proximity to the machine, always carrying the risk of accidents. With NC machine tools, once the program is set, the operator has no need to be in the immediate vicinity of the machine. This reduces the risk of injury or accident from the operator coming in contact with the machine, making for a safer workplace environment.

Disadvantages of Deployment

While deploying NC machine tools does have several advantages, there are also some issues and caveats to consider. Next up are some key points and issues for deployment to consider.

Deployment Costs

One drawback of NC machine tools is the high initial investment. Especially when it comes to high-performance models and large models, it is not uncommon for the capital investment to reach the tens of millions of yen. However, despite the initial costs involved, automating tasks will reduce labor costs and, if selecting an energy-saving model, it can be expected to reduce electricity costs as well. Therefore, when introducing NC machine tools, it is important to think out your management strategy and budget carefully, and to formulate a recovery plan from a long-term perspective.

Changes to Work Procedures

The introduction of NC machine tools will require different work procedures and thinking than manual machining. In particular, it will require NC programs to be created and the machines to be setup, and CAD and/or CAM software will be required for any complex programs. Therefore, it is essential to work to build an environment where employees can deepen their understanding of NC machine tools through training and study sessions.

What Operations are More Suited to Universal Machine Tools?

NC machine tools are generally better at machining products with at least a certain production volume, or machining of complex shapes. They are not suited to production of prototypes that are machined by trial and error. In addition, there are cases, such as for minor modifications to finished products or individual part machining, where it is faster to use universal machine tools. When considering the introduction of NC machine tools, it is important to take into account your application and production volume to make the right choice.

Key Points in Selecting an NC Machine Tool

To this point, we have covered the advantages to introducing NC machine tools and points to note, but simply acquiring NC machine tools will not be enough to extract the full effects of introduction. Here are the key points to keep in mind during an introduction.

Consider Deployment Costs and Running Costs

The introduction of NC machine tools is a capital investment. And when companies make a capital investment, they do so expecting profits that are commensurate with the capital investment. It is necessary to use calculations of things such as return on investment and payback period to predict the costs that will be incurred after introduction. At this time, in addition to the costs for introduction, also calculate the running costs, and compare them with the expected profit and profit margin when NC machine tools are deployed.

Judge the overall cost performance, considering factors such as the reduction in electricity costs from any energy savings and reduction in labor costs from automation.

Select Machine Tools That Match Machining Objectives

No matter how good an NC machine tool is, there is no one-size-fits-all machine suitable for all machining objectives. Each machine tool has its own specific machining features and performance. When considering the introduction of new machine tools, selecting the best machine tool for your machining objectives is essential to improving production efficiency and producing high-quality products.

For example, if the goal is mass production, it is better to choose a machine capable of high-speed, continuous machining. On the other hand, if expecting to manufacture parts with complex geometry, choose a machine that is good at precision machining or a 5-axis machining center.

Brother offers a wide variation of machine tools. Find out which ones have the right performance for your goals.

Brother Industries, Ltd. Machine Tools Products List

Developing an Employee Education Program

When introducing NC machine tools, employee education is essential. Operation and programming require specialized knowledge and skills, making it essential to properly educate employees and strive to draw the utmost out of the machine. Other than holding study sessions and in-house training, the educational programs provided by machine tool manufacturers can also be effective.

The Future and Evolution of Machine Tool Technology

NC machine tools have already become the prevailing trend in the manufacturing industry. The technology is developing daily and is sure to become a means to solve the worsening issues of succession and declining workforce. Lastly, let’s have a look at the future direction of NC machine tools.

Technological Breakthroughs

In recent years, NC machine tools that can machine at multiple points with a single chucking have penetrated the market. These are shortening work processes and improving production efficiency, and automating even those tasks such as workpiece mounting and removal, which were previously performed manually.

In addition, efforts are underway to link machine tools and industrial robots. By incorporating the latest technologies in IoT, AI, and 5G, a future in which all machines work in conjunction with each other and which requires almost no manual input is now within reach for manufacturing. While currently still in the demonstration phase, “smart factories” based on the concepts of automation, manpower reduction and unmanned operations will surely become mainstream in the future.

Machining Support Software Is Evolving

Alongside the physical evolution of machine tools and factories, machining support software is also developing rapidly. A typical example is simultaneous 5-axis machining, in which multiple axes are controlled simultaneously while machining. Advances in 3D modeling and simulation technology have made possible verification in a virtual environment before actual machining is performed.

In addition, systems are being developed to acquire various information, such as the detailed tool path and the amount of tool wear, and have it reflected in the machining program. If machine learning is built into these systems, big data such as for formerly made products and manufacturing processes may be utilized to create machining software that optimizes the program itself.

Quantify and Pass on Company Technology

When highly experienced employees with proprietary technology leave the company, their know-how will be a big loss for the company. However, the smart factories and machining support software introduced above will allow for technologies and know-how that were previously held by individuals to be quantified and store them as a database.

This will both increase production efficiency and also help to educate and train new employees based on that information. NC machining and various other technologies are key to passing on the valuable know-how of a company to the next generation.

If your company is considering an introduction or is currently experiencing issues, contact us for a consultation.

Brother Machine Tool Inquiries

Author: Yuki Kobayashi

Editor: EGGO CO., LTD.

Related Articles

Basics of Non-Ferrous Metals Used in Machining! Difference From Iron and Steel, and Features of Each Material Explained