Learn the Rules for Metal Material Codes! The Meaning and Reading of JIS Codes Explained

In the manufacturing industry, correctly understanding JIS-designated material codes is essential when choosing machining materials. At first glance, these material codes may appear complex, but once you understand the system, they allow you to efficiently assess a material's type, application, and properties.

This article explains the meaning and reading of codes for iron and steel and non-ferrous metals using concrete examples. Be sure to check it out, as correctly understanding material codes will help you choose suitable materials and improve work efficiency.

Metal Materials Are Divided Into Two Types: "Iron and Steel" and "Non-Ferrous Metals"

Used as industrial materials, metal materials can be broadly classified into two categories: "iron and steel" and "non-ferrous metals." Iron and steel is one of the most commonly used materials, accounting for the majority of all metal materials. Iron and steel are abundant resources and are relatively inexpensive. They are characterized by their excellent strength and workability. Their properties can also be adjusted through heat treatment.

Non-ferrous metal materials, on the other hand, are used to take advantage of properties that iron and steel materials do not have, such as light weight (aluminum, magnesium), electrical conductivity (copper), and corrosion resistance (titanium).

Meaning of JIS Material Codes

JIS material codes specify the following key properties of metal materials.

- Material

- Material shape or type

- Application

- Tensile strength

- Manufacturing method

Specifically, JIS material codes can be divided into the following three elements.

| Code indicating material | Indicates the basic material type, such as S (steel), F (iron), A (aluminum), or C (copper). In many cases, the code is based on the alphabet or chemical symbol. |

|---|---|

| Code indicating product name or application | Indicates the product type or application based on shape, such as US (Use Stainless), P (Plate), or W (Wire). |

| Number indicating material property | Indicates tensile strength (e.g., the "400" in SS400 is 400 N/mm2), number showing material type (e.g., the "304" in SUS304), or carbon content (e.g., the "45" in S45C is 0.45%). |

Why Are Material Codes Established?

One of the reasons for establishing JIS material codes is to efficiently express the properties and applications of materials, helping prevent confusion in manufacturing and transactions. Material codes make it possible to quickly assess a material's basic properties (strength, corrosion resistance, etc.) and intended use, and are useful for choosing appropriate materials and setting machining conditions.

Standardized codes also facilitate clearer communication in international trade.

What are the JIS standards?

The Japanese Industrial Standards (JIS) are national standards that define specifications and measurement methods for industrial products in Japan. Originally developed as standards for industrial products, JIS now plays a central role in standardizing a wide range of fields, including information processing and services. Its goals include ensuring compatibility across products and services, guaranteeing quality and safety, and improving production efficiency.

Material Code Rules for Iron and Steel

As discussed above, the codes for iron and steel materials mainly consist of three elements: material, product name, and number.

For example, for the structural steel material "SS400," the first "S" stands for steel, the second "S" stands for structure, and the "400" indicates a minimum tensile strength of 400 N/mm². Similarly, in the case of carbon steels for machine structural use "S45C," the "S" stands for steel, and the "45C" indicates a carbon steel with a carbon content of 0.45%.

List of Iron and Steel Material Codes

Examples of types and codes for iron and steel materials are given below.

Structural steels

- SS: Rolled steel for general structure

- SM: Rolled steels for welded structure

- SMA: Hot-rolled atmospheric corrosion resisting steels for welded structure

- SGD: Rolled carbon steel for cold-finished steel bars

- SSC: Light gauge steel sections for general structure

- SWH: Welded light gauge steel H sections for general structure

Machine structural steels

- S-C: Carbon steels for machine structural use (the "-" indicates the carbon content)

- SCM: Chromium molybdenum steel

- SCr: Chromium steel

- SNC: Nickel chromium steel

- SNB: Alloy steel bars for special application bolting materials

Tool steels

- SK: Carbon tool steel

- SKC: Hollow steel

- SKS (SKD, SKT): Alloy tool steel

- SKH: High speed tool steel

Material Code Rules for Non-Ferrous Metal

Similar to iron and steel, the codes for non-ferrous metal materials are systematically defined. Aluminum begins with "A" and copper with "C," followed by a code indicating the alloy type and shape.

As a general rule, the designation for aluminum consists of an A followed by "a four-digit number indicating the alloy type" and "a letter indicating the shape." The same applies to copper, where C is followed by "a four-digit number indicating the alloy type" and "a letter indicating the shape."

The final letter in the code, which indicates the shape, includes "P" (plate), "B" (rod), "T" (tube), and "W" (wire).

List of Non-Ferrous Metal Material Codes

Examples of types and codes for non-ferrous metal materials are given below.

Aluminum

- A1000 series: Pure aluminum

- A2000 series: Aluminum-copper alloy (duralumin)

- A5000 series: Aluminum-magnesium alloy

- A6000 series: Aluminum-magnesium-silicon alloy

- AC: Aluminum alloy ingots for casting

- ADC: Aluminum alloy ingots for die casting

Copper

- C1100: Tough pitch copper

- C2600: Brass

- C3604: Free-cutting brass

- C5111: Phosphor bronze

- C1720: Beryllium copper

- C1990: Titanium copper

Others

- N: Nickel ingots

- MI: Magnesium ingots

- MD: Magnesium alloy die castings

- ZDC: Zinc alloy die castings

- WJ: White metal

JIS Material Codes Are Essential Information on the Manufacturing Floor

JIS material codes are essential information for efficiently selecting materials and conducting transactions. They begin with "F" or "S" for iron and steel materials, and "A" (aluminum) or "C" (copper) for non-ferrous metals. These codes are designed to convey material type, application, and properties at a glance. Understanding this symbol system improves work efficiency on the manufacturing floor, particularly in material selection and quality control. However, material codes only indicate basic properties. Actual use of materials must also consider factors such as heat treatment conditions, machining methods, and the usage environment. Furthermore, as technological advances continue to drive the development of new materials and machining methods, it's essential to stay informed and up to date with the latest information.

Author: Yuki Kobayashi

Editor: EGGO CO., LTD.

Related Articles

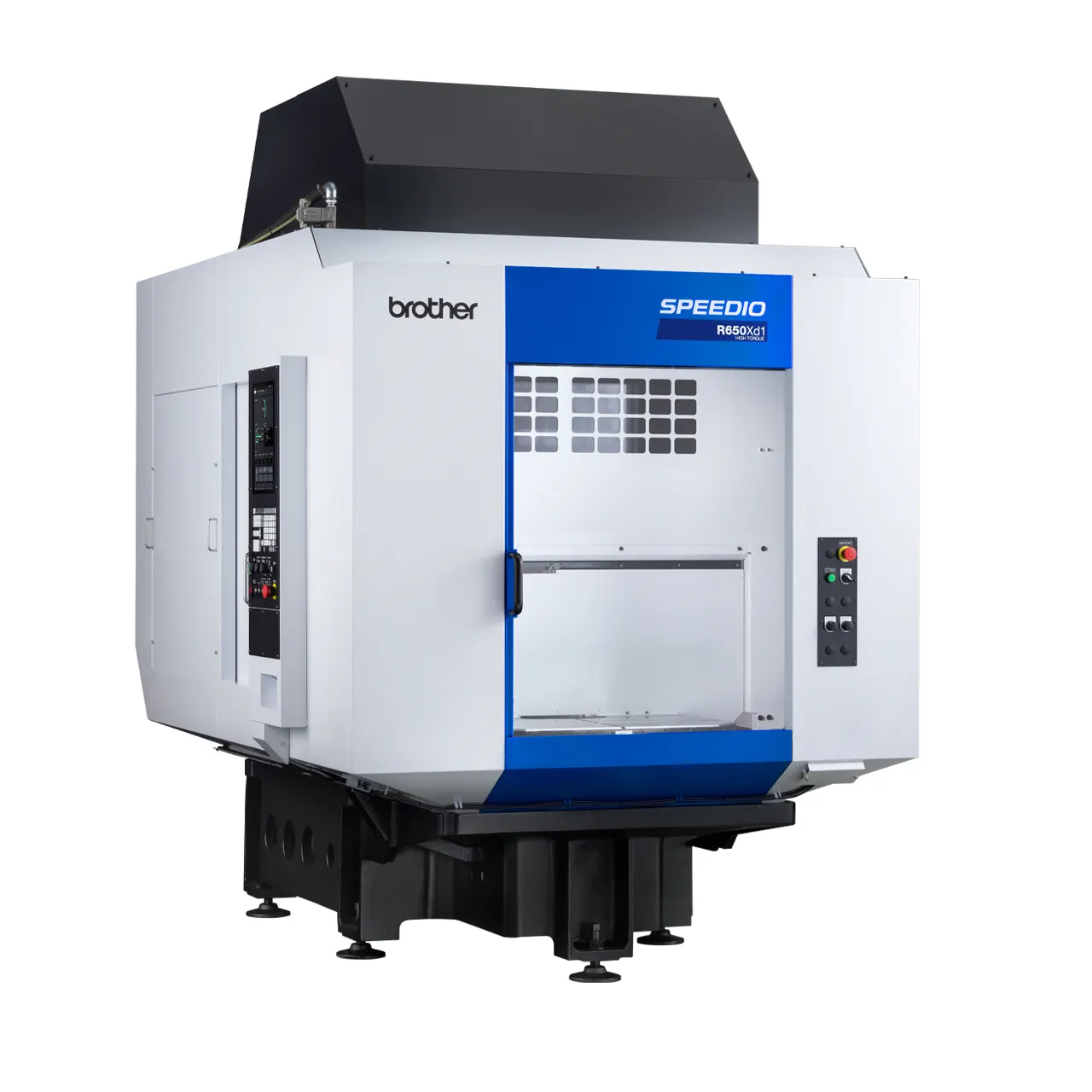

Reduce Wasted Space With SPEEDIO Blue Technology