The Process of Making Die-Cast Parts Explained! What to Watch Out For

Die-casting is a casting technique used to manufacture parts for various products that are indispensable to our daily lives. How is die-casting done? This article explains the process for creating die-cast parts and points to keep in mind when manufacturing them.

Die-Cast Parts Are Used in a Wide Range of Products

Die-casting technology, which involves melting and molding non-ferrous metals such as aluminum and zinc in dies, enables the mass production of parts with complex three-dimensional shapes. As a result, die-cast parts are used in a wide range of products.

Die-cast parts are especially prevalent in the automotive industry, where they are used in various components such as cylinder blocks, oil pans, and transmission cases. They are also used in both business and household products, including headsets, smartwatches, televisions, tablets, printers, washing machines, and refrigerators.

Die-Cast Part Manufacturing Process

How are die-cast parts—used as parts in a wide range of products—made? To create die-cast parts, a mold is required. After receiving an order, the mold is first designed and produced, and then finished.

In the actual manufacturing of the die-cast part, the process involves sourcing raw materials, melting them, casting them in a die casting machine, trimming, deburring, and inspection, followed by post-machining to create the finished die-cast product.

Trimming refers to the removal of non-product sections from the casting. This can be done using a machine such as a trimming press or by hand. Deburring is the process of removing "casting burrs" that form on the parting lines with the mold. It is performed to remove unwanted bumps and finish the product surface.

The material removed during trimming is treated as return material and reused as raw material. The die-cast part manufacturing process is explained in more detail in the next section.

1. Molding Process

The molding process refers to the process of producing molds. Molds consist of at least two parts, allowing the die-cast part to be removed after casting. These two parts are called the fixed mold and the movable mold. The fixed mold is attached to the fixed platen, while the movable mold is attached to the movable platen of the die casting machine.

2. Melting Process

The melting process refers to the process of melting the metal used to make parts into a liquid state. The liquid metal is called "molten metal." The metal used for melting and pouring may consist not only of ingots but also of scrap and return material used and returned from previous castings.

Melting is carried out in an electric furnace, during which impurities are also removed. Purity increases as the impurities that rise to the surface with increasing temperature are removed. After melting, controlling the temperature of the molten metal is essential. Temperature control is performed to ensure that the metal remains in a liquid state and prevent it from cooling down and solidifying.

3. Casting Process

*The above diagram is an illustration and may differ from the actual product.

The casting process involves pouring molten metal into a mold. To create products with highly accurate dimensions, the speed and temperature at which the molten metal is fed must be controlled. If the casting operation is not performed properly, the cast metal may be deficient. For example, "poor metal flow" occurs when the molten metal fails to fill the mold completely, resulting in a short shot.

4. Post-Processing

Post-processing refers to the steps performed after casting is complete and the product is removed from the mold. The removed cast metal includes unwanted sections and burrs, which require trimming and deburring. Burrs form in die-cast parts due to a mold mismatch or galling as the product is released from the mold.

It is also important to note that products may be prone to forming burrs depending on the structure of the part being manufactured. For products with relatively simple shapes, deburring may be performed during the trimming process. However, products with complex shapes often require multiple steps with deburring.

The unwanted section generated at this stage is reused in product manufacturing.

5. Post-Machining Process

In this process, drilling and thread cutting may be performed after casting. Additionally, machining may be performed using lathes, milling machines, or grinding machines to improve dimensional accuracy and surface roughness.

Deburring Methods for Die-Cast Parts

As mentioned above, deburring is essential in manufacturing die-cast parts.

Impact of Burrs

Burrs that remain on die-cast parts can interfere with adjacent parts or reduce performance. They may also pose risks by falling off or causing injury to workers.

Therefore, die-cast parts are deburred mainly by using hand tools, presses, or machines.

Deburring Using Hand Tools

In manual processing, burrs are removed using a pneumatic tool called an air file. Because the work is done by hand, the quality may vary depending on the worker's skill level. Manual deburring is commonly used for small-lot products.

Deburring Using a Press

This method uses a press and press die to perform trimming and deburring simultaneously. However, it requires the production of a custom press die tailored to the specific die-cast part, which adds cost.

Deburring Using a Machine

Mechanical deburring removes burrs simultaneously while machining, which is often performed to enhance product precision.

What to Watch Out for When Manufacturing Die-Cast Parts

There are several points to watch out for when manufacturing die-cast parts.

Check if the Material Is as Intended

Quality control is essential when manufacturing die-cast parts. To ensure the material has the required mechanical properties to produce the desired part, microstructural observation is performed to confirm that the material meets specifications. Microstructural observation is performed by cutting a sample, polishing the surface, and inspecting it visually or with a microscope.

The proportion of raw materials and additives, casting conditions, and other variables are adjusted to produce material that meets specifications.

Check for Porosity

It is also important to check for voids (porosity) caused by trapped gas or air during casting. Porosity can reduce strength and airtightness. Cut a sample, clean and finish the surface, and check for porosity.

Check for Cracks

Cracks may occur in die-cast parts even after delivery. Cracks are caused by residual internal stress due to shrinkage during casting. Because cracks can develop over time after casting, checks are required not only immediately after casting but also during shipping inspection.

Check for Poor Metal Flow

In addition, check for poor metal flow—when the molten material fails to completely fill the mold, resulting in incomplete filling or thin walls. Aside from visually checking the flow of metal around thin-walled areas and corners, cut the part after casting and check for wrinkles.

Check for Size or Shape Defects

Although die casting generally produces parts with high dimensional accuracy, care must be taken as defects in shape or size can still occur. Molds are designed and produced with shrinkage and deformation in mind. However, accuracy may be compromised due to incorrect estimates or wrong mold dimensions.

Check if the Specified Strength Is Met

Cooling speed and uneven cooling of the molten material until solidification can alter the microstructure, leading to reduced strength. Porosity and poor metal flow can also cause a decrease in strength. It is important to confirm that the specified strength is met by taking several samples and performing tensile tests.

Because these quality control procedures require the cast parts to be completely destroyed, extra parts must be produced in advance as samples.

Post-Machining Is Required to Complete Die-Cast Parts

The use of die-casting technology enables the creation of parts in a wide variety of shapes. Before die-cast parts can be shipped, post-machining is required to improve precision and remove burrs. Parts with complex shapes may undergo numerous processes from the time they are ordered until shipment.

Furthermore, manufacturing die-cast parts requires quality control across several areas, including checks for porosity, cracks, and strength. Businesses considering contracting for the manufacturing or deburring of die-cast parts must take into account the points to watch out for when manufacturing die-cast parts and establish inspection and control systems.

Author: Miyuki Takahashi

Editor: EGGO CO., LTD.

Related Articles

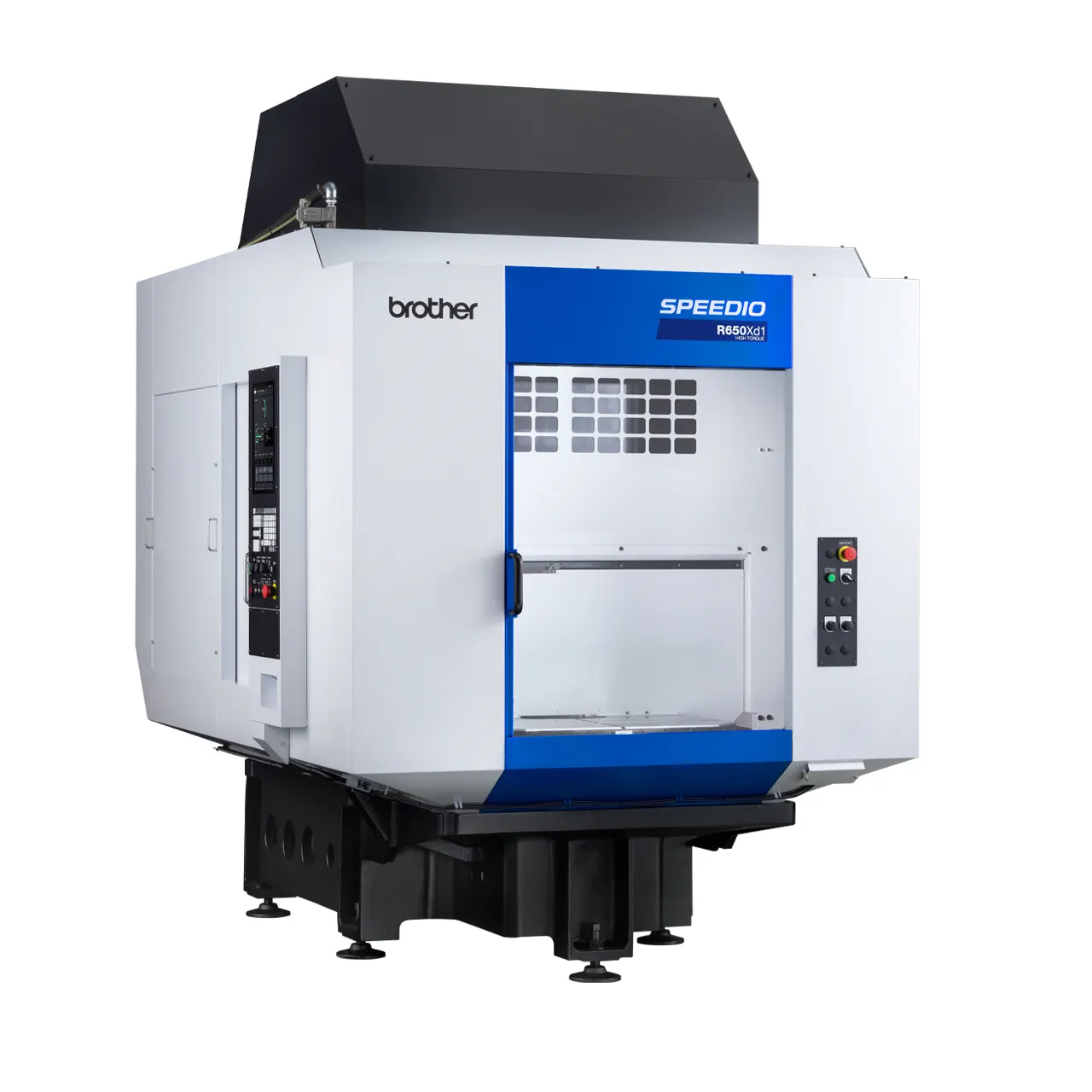

Reduce Wasted Space With SPEEDIO Blue Technology