What Is an End Mill? Learn the Characteristics, and Pick the Right One From an Abundance of Options

End mills are a typical cutting tool used in milling machines, machining centers, and other machine tools. The various types include square end mills, ball end mills, and roughing end mills, all classified into multiple types according to thickness, length, and material.

This makes end mills a highly complex subject, and selecting the right tool for a given task is no simple matter. To ensure proper end milling with an understanding of the types and characteristics, this article provides a comprehensive overview of the types, characteristics, and selection of end mills.

What Is an End Mill?

End milling is one of the most basic milling techniques. This section will provide basic knowledge on end mills that you may be afraid to ask.

End Mills Are Cutting Tools Used in Milling

End mills are cutting tools which are mounted to milling machines and machining centers. A tool attached to the spindle of a milling machine is called a milling tool. Among these, a tool with blades (known as flutes), not only on its sides but also on its bottom, is called an end mill.

With end mills, the workpiece is cut by the flutes as they rotate. End mills can be used in a wide range of machining methods, including side cutting, groove machining, and finishing, and are used in various fields such as mechanical parts, molds, aerospace, electronic components, and medical equipment.

What Is End Milling?

As the name suggests, end milling refers to a series of cutting operations performed using end mills. Specifically, it includes the following machining techniques:

- Groove Machining

- Side cutting

- Taper Machining

- Copy milling

- Pocket milling

End milling can be performed on universal milling machines, machining centers, multi-tasking machines, and other machine tools. End milling is usually performed manually when done with a universal milling machine, but with NC, a work process design can be programmed for high accuracy and efficiency in machining.

End Mill Is Highly Versatile and Capable of Various Types of Machining

End mills typically have 1-10 flutes, with different flute counts used for different purposes. They are further categorized by variables such as structure, material, geometry, and flute count, each of which has a suitable application. Whereas other machine tools, such as drills and reamers, are job-specific tools, end mills are not. With flutes on both the sides and bottom, end mills can perform various machining depending on how they are moved.

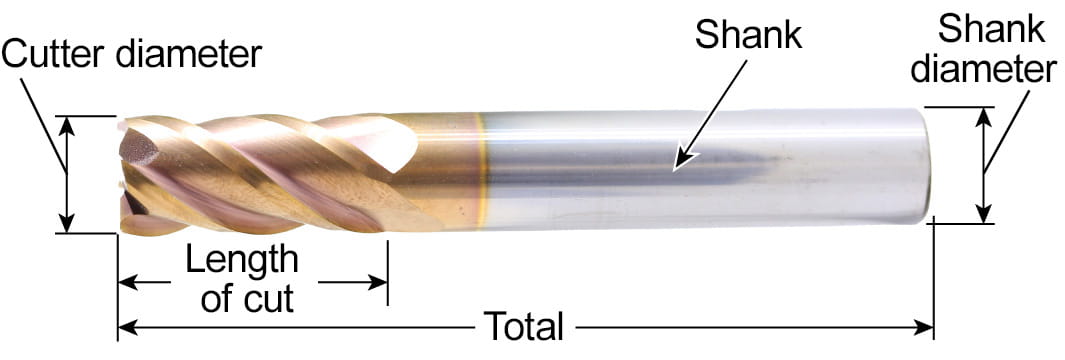

End Mill Part Terminology

End mills are comprised of parts named as shown in the figure above. Each has the following roles and meanings:

- Length of cut (tip): Length of the flutes at the tip

- Cutter diameter: Diameter at the flutes

- Shank: The body part of the end mill

- Shank diameter: Diameter at the shank

Two Structural Types

End mills are subdivided based on structural differences into two types: Solid and throwaway. Solid end mills have the flutes and shank ground from a single piece, and when the flutes wear down, the cutting edge can be resharpened and reused. Meanwhile, throwaway end mills have replaceable heads or inserts. With these, cutting performance can be restored by replacing worn flute tips with new ones.

Differences From Drills, Taps, and Reamers

End mills are versatile tools that can perform various modes of machining. How do they differ from other cutting tools in drills, taps, and reamers? Here are the differences between end mills and these other tools.

End Mills vs. Drills

Drills, as a cutting tools used for milling, specialize in drilling. The tool tip has flutes that evacuate the chips via grooves engraved into the sides of the tool. Although similar in appearance to an end mill, drills have a sharp, pointed tip and are not designed for side cutting.

End Mills vs. Taps

A tap is a cutting tool for cutting a helical thread for screws inside a hole in the workpiece. Unlike end mills, taps specialize in cutting out the precise shape of a screw. They are used for thread cutting and nothing else. Taps are subdivided into two types: Cutting taps and roll taps.

Cutting tap: Cuts the root of the threaded hole to create the grooves

Roll tap: Applies pressure to the threaded hole to push out the thread grooves

End Mills vs. Reamers

In contrast to taps, which create a thread inside a hole, a reamer is a tool that smooths the internal surface of a hole. While the main point of end milling is to machine the workpiece, reaming is performed to fine-tune the inner diameter of an existing hole.

Difference and Usage by End Mill Peripheral Cutting Edge Geometry

Next, we will explain the types of end mills as classified by the difference in the peripheral cutting edge.

Square End Mill

A square end mill has a square profile to the cutting edge. The cutting edge has 90-degree sharp edges and a flat bottom. These are suitable for machining right-angle corners and planes, and they are used in a wide range of scenarios for their versatility.

Ball End Mill

A ball end mill is a cutting tool with a hemispherical cutting edge. This tool can perform various modes of machining, but it is particularly suited to cutting curved surfaces and three-dimensional shapes. However, since the cutting edge is rounded, the finished surface after machining tends to be rough and may require finishing.

Radius End Mill

Radius end mills have rounded edges on the bottom corners. It has a smooth curve instead of a dish angle, so it is suitable for adding corner radius to a workpiece. These features make the cutting edge less prone to breaking, and as such, they are used for workpieces of high hardness and other heavy cutting.

Roughing End Mill

As the name suggests, roughing end mills are suitable for rough machining. The bottom surface is flat, and the side cutting edges are serrated with fine grooves. When cutting, chips enter the grooves and are rendered into small pieces as the tool rotates. This makes for better chip evacuation and limits the decrease in machining accuracy.

Tapered End Mill

On a tapered end mill, the tool progressively narrows toward the cutting edge. These are often used to add a slope or inclination to the workpiece, and can also be used to machine holes and grooves with a tapered angle.

Differences by End Mill Size (Diameter and Length)

Next, we'll look at end mill size and diameter. Differences in terms of thickness or length will give different characteristics, so these differences will be explored in detail.

Size is Shown in mm or φ

Cutter diameters for end mills are indicated in mm or φ (Phi), ranging from fine cutting edges of a few mm to ones exceeding 10 cm in diameter for heavy cutting. End mill size is selected according to the size of the workpiece to be machined and the required accuracy. For example, a 6 mm (6 φ) end mill is used when groove machining to 6 mm.

Is Longer Better?

End mills with a longer length of cut can machine a wider area at once, increasing the cutting efficiency. However, while longer end mills are suitable for machining deep holes and grooves, they are also more prone to bending. When precision machining is required, it is necessary to relax the cutting conditions and devise ways to suppress vibration.

Differences and Features by End Mill Flute Count

Flute count also greatly impacts end mill performance. What are the differences between end mills with more or fewer flutes, or even and odd flute counts? A review of the characteristics of each follows.

Chip Evacuation Performance

Generally speaking, the lower the flute count, the wider the chip pocket (gap between flutes) and the more chip evacuation there is. As the flute count increases, however, core diameter and rigidity increase, reducing chip evacuation. For applications where chip evacuation is not required, such as side cutting, end mills with a higher flute count are used.

Rigidity

End mill rigidity is also related to flute count. When cutting the workpiece, resistance is generated in the opposite direction of end mill travel. In general, the higher the flute count the thicker the core is, and the less deflection there is during machining. However, increasing the flute count also increases the cutting resistance, so it is important to set cutting conditions to balance the rigidity and cutting resistance.

Vibration Resistance

Vibration tends to occur when cutting hard materials, so end milling requires sufficient rigidity. As vibration impacts machining accuracy, end mills with at least four flutes are generally selected when cutting hard workpieces. Another method used for cutting hard materials is to use an end mill made of cemented carbide.

Advantages of 3, 5 and Odd Numbers of Flutes

There are odd and even flute count end mills, with even flute count end mills probably seeing more usage in actual manufacturing sites. However, odd count end mills have the advantage of being less prone to vibration. With an odd count end mill, such as a 3-flute or 5-flute end mill, vibration during machining can be suppressed somewhat as the flutes are not diametrically opposed. However, an odd number of flutes makes it harder to measure end mill diameter, so cutter diameter must be measured using a special measuring instrument when using odd flute count end mills.

Machining Examples and Flute Count Estimates

End mill flute counts vary from one to ten. As already explained, there is a trade-off between chip evacuation and rigidity, so it is important to select the right tool for the application. For example, for groove machining, end mills with a lower flute count, such as a 2-flute end mill, are used for their higher chip carrying capacity. Meanwhile, 4 to 6 flutes are more suited to surface machining, producing a smoother, more uniform surface finish than end mills with fewer flutes.

Classifying End Mills by Material

End mills can also be classified by material. It is important to select the end mill material according to the workpiece material to be machined. Doing so will improve machining quality and extend tool life.

HSS End Mill

High speed steel (HSS) end mills, also known as high-speed steel tools, are more commonly used than carbide end mills to be described below, and they are suitable for machining materials of low to medium hardness. HSS end mills are flexible and less prone to damage, making them more affordable than highly rigid carbide end mills.

Carbide (Tungsten) End Mill

Carbide end mills are made of a highly resistant material called cemented carbide. These are better for hard materials and high-speed cutting, and they are also highly resistant to cutting heat. Carbide end mills are able to withstand more than 10 times the cutting speed of an HSS end mill, which is why they are that much more expensive.

End Mill Life

The lifetime of an end mill will largely depend on frequency of use and machining conditions. Many end mills can be reused by sharpening the flutes. Sharpening the flute bottoms shortens the overall length of the end mill, while sharpening the peripheral cutting edges shortens the cutter diameter.

With the combination of factors that determine end mill life, such as the type of end mill, cutting conditions, and resharpening methods, it is important to use the end mill in line with its characteristics to make it last longer.

End Mill Selection and Calculation Formula for Cutting Conditions

We will close with some words on how to choose an end mill. The tool to choose will depend on the material to be machined, the cutting conditions, and the cutter diameter of the end mill.

Setting Cutting Conditions for End Milling

Many factors come into play when setting the cutting conditions for end milling, such as material of the workpiece and the material, outer diameter, and flute count of the end mill. Setting the right cutting conditions can help to avoid tool breakage and machining errors, and to maintain machining accuracy.

Formulas for Calculating Cutting Conditions

Cutting conditions are calculated using factors including rotational speed, cutting speed, feed rate, and feed rate per flute. These conditions are adjusted according to the workpiece material and tool characteristics. Some example calculation formulas are shown below. Note that some NC machining centers can automatically calculate these cutting conditions.

-

Formula for rotational speed: N = (1,000 × V) / (π × D)

- V: Cutting speed

- π: Pi

- D: Tool diameter

-

Formula for cutting speed: V = π × D × N / 1,000

- π: Pi

- D: Tool diameter

- N: Tool rotational speed per minute

-

Formula for chip evacuation: Q = ap × ae × F / 1000

- ap: Axial depth of cut

- ae: Cutting width

- F: Feed rate per minute

-

Formula for table feed rate: F = f × z × N

- f: Feed rate per flute

- z: Flute count

- N: Tool rotational speed per minute

Understanding End Mill Characteristics to Improve Work Quality and Efficiency

End mills are subdivided according to cutting edge structure and size, flute count, and other variables. Thus, in end milling, it is important to understand the differences of each type and choose the right tool. Incorrect settings can lead to chipping and machining errors, which in turn can affect production profits.

Brother's SPEEDIO series of machining centers comes equipped with an interactive program to assist in aligning tool selection with the workpiece material and cutting conditions. It also comes with an automatic tool changer loaded with multiple tools, minimizing the hassle of tool changes and selection. Come see one in action in our showrooms nationwide, or feel free to contact us.

Author: Yuki Kobayashi

Editor: EGGO CO., LTD.

Related Articles

What Is Cutting Speed? Calculation Formula and How to Determine Cutting Conditions