What Is the Power of the Evolving BT30? And a Comparison With the BT40

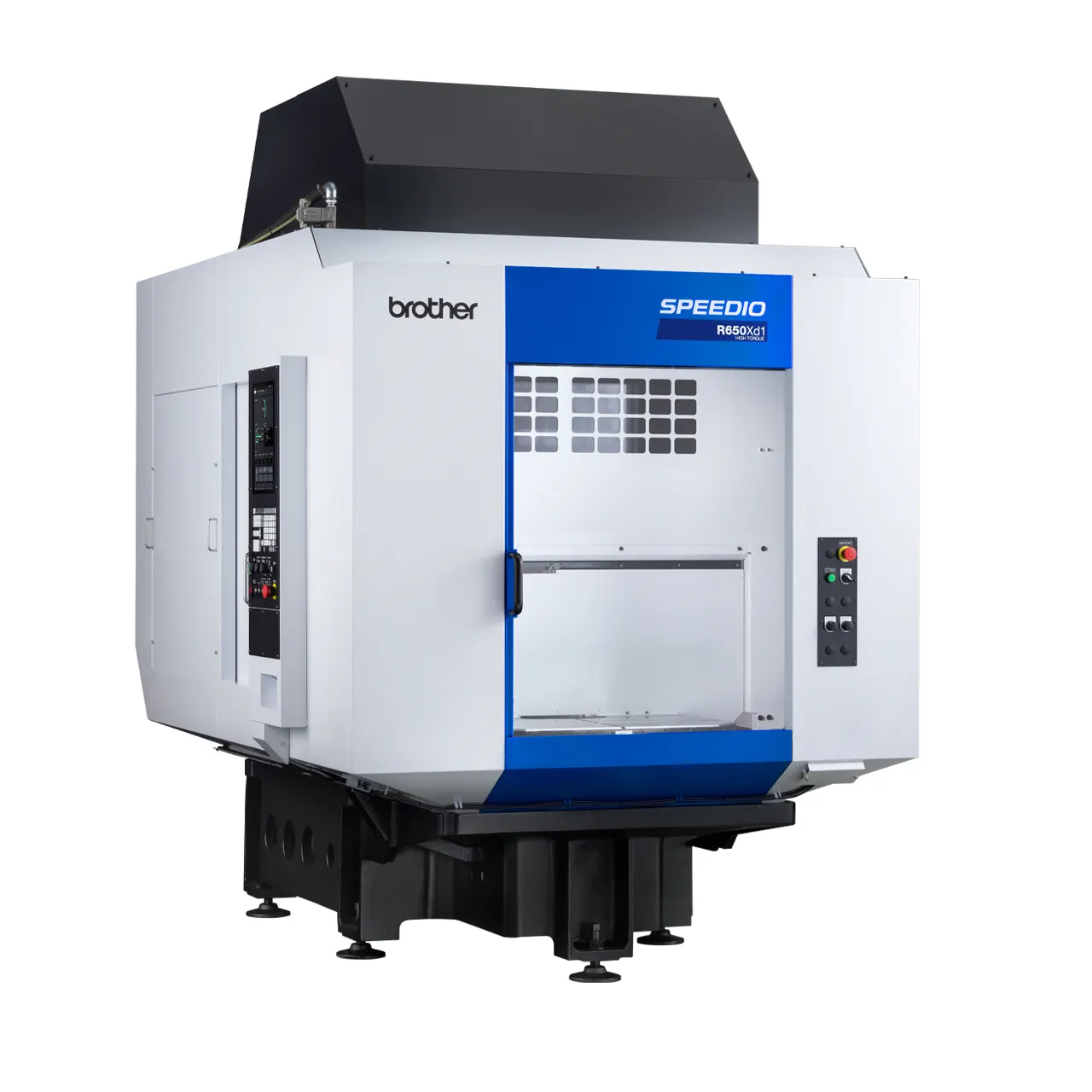

While compact machine tools have a reputation for occupying less space and consuming less power, they also have a reputation for not being able to machine large objects and for lacking rigidity. In this article, we will feature the SPEEDIO series developed for BT30, and how it differs from the conventional image of compact machine tools.

SPEEDIO Series Developed for BT30

SPEEDIO series is a series of compact machining centers launched by Brother in 2013. Brother originally made its machine tools for the in-house production of key parts for their sewing machines. In 1985, they launched their tool as a CNC tapping center for sale to the world. Since then, it has been highly regarded as a compact machine tool with high productivity and environmental performance.

In 2013, Brother rebranded its line into the SPEEDIO series. By adopting the BT30 spindle and equipping them with in-house developed NC, SPEEDIO tools feature high-speed operation and optimal control. When the SPEEDIO series was launched, demand for smartphones was exploding, both in Japan and overseas. As a result, the SPEEDIO series saw frequent use in machining smartphone housings, and sales volume increased steadily immediately after its release.

More recently, the whole world, not limited to the manufacturing industry, has striven to save more energy. With this push, demand has increased for light and durable aluminum parts, especially for automotive parts. Consequently, demand for machining of aluminum parts has also increased. Furthermore, since aluminum is much more recyclable than other metals, it is easier to procure materials domestically in Japan. This also boosts the demand for machined aluminum products.

The compact and nimble SPEEDIO series of machine tools pairs well with this future demand for aluminum and energy saving in factories. In addition, the new SPEEDIO series models have a revamped user interface designed to be easy for anyone to use.

BT30 Advantages

BT30 machine tools offer three advantages:

- High productivity

- Compactness

- Energy saving

BT30 spindles are lighter than BT40 for more agile operation. The lighter spindle can be moved quickly even at lower power consumption, and the reduced impact from the spindle moving and stopping make spindle operation more agile. To some extent, the machining speed of a machine tool is determined by the material quality and machining conditions. In essence, this means that non-machining time, such as tool changes and tool travel, must be shortened to increase productivity. With their agile operation, BT30 machine tools can shorten these times.

BT30 machine tools are generally smaller than BT40 tools. Thus, they don't take up space on the factory floor. This will also depend on workpiece materials, of course, but factories producing mostly relatively small workpieces and working a lot with soft materials like aluminum can potentially save floor space by deploying compact BT30 machine tools.

BT30 spindles are smaller and lighter than BT40 spindles. In addition, the tool attachments for the spindle are also more compact and lighter than their BT40 counterparts. Thus, it takes less power to move the spindle, and for the same machining, the machine tool can be moved with less power than with BT40. While true that larger tools can machine large and small products, using a large tool to machine small products will be a waste in terms of power consumption. A machine tool with a smaller, lighter BT30 spindle can be expected to reduce power consumption and save energy.

BT30 Disadvantages

BT30 machine tools also have their disadvantages. Impressions of BT30 tools include:

- Hard to machine large parts

- Due to inferior rigidity, difficult to machine hard materials

Compactness was listed above as an advantage of BT30 machine tools, but this does also give the impression that it has trouble machining large parts due to its limited table size and cutting tool range of motion. In addition, impressions are that the thinner spindles lack rigidity and have trouble machining hard materials.

However, the SPEEDIO series also includes models that can reverse these apparent disadvantages common to BT30 machine tools.

W1000Xd2 for Wide Cutting

When having trouble machining large parts, the W1000Xd2 is recommended for wide cutting.

The W1000Xd2 has a large machining area for its compact body. The W1000Xd2 machining area is 1000 mm (39.4 inch) wide and 500 mm (19.7 inch) deep.

The machining area of the typical BT30 machine tool is approximately 700 mm (27.6 inch) wide and 400 mm (15.7 inch) deep, whereas that of a typical BT40 machine tool is approximately 1050 mm (41.3 inch) wide and 530 mm (20.9 inch) deep. Thus, the W1000Xd2 machining area is almost equivalent to that of a BT40 tool.

A large machining area and table have more advantages than just the ability to machine larger products. This also allows for multiple jigs to be placed on the table. Using multiple jigs can reduce machining time by allowing for machining requiring two models or multiple processes to be machined at a time.

In addition, with the compact size and energy saving of a BT30 tool, the W1000Xd2 should help in greatly reducing running costs in your factory.

F600X1 for Increased Spindle Rigidity

For those who find hard materials difficult to machine with a BT30 machine tool, we recommend the F600X1.

Compared to our conventional SPEEDIO series tools, the F600X1 has greatly increased spindle rigidity thanks to improvements such as larger spindle bearings and a wider spindle support span. These changes result in a rigidity ratio approximately 1.5 times higher than that of previous SPEEDIO series tools. This enables the F600X1 to machine hard materials that have conventionally been difficult to machine with BT30 tools.

While still smaller than the W1000Xd2, the F600X1 machining area is on par with smaller BT40 tools. Therefore, it is quite close to BT40 tools in terms of both machine tool rigidity and the size of machinable parts. For those with reservations about the rigidity of standard BT30 tools that find a BT40 tool to be a little big to introduce, the F600X1 model is just right for machining somewhere in the middle.

* The information provided here is current as of the time of publication. For details on the latest models, please contact us.

Expanded BT30 Coverage

SPEEDIO is a series of compact machining centers launched by Brother in 2013. By adopting BT30 spindles, SPEEDIO tools are compact and consume less energy. In addition, the SPEEDIO lineup includes models that overcome the conventional disadvantages of BT30 tools, such as the smaller machining area and difficulty in machining hard materials. The series is the answer to our customers’ requests for waste-free machining capability.

Author: Reiko Ishikawa

Editor: EGGO CO., LTD.

Related Articles

Reduce Wasted Space With SPEEDIO Blue Technology