Changes in the Metalworking Industry With the Automotive Industry's Shift to EVs

The world is progressively shifting to electric vehicles (EVs) with the goal of decarbonizing our society. With automobiles accounting for such a large share of the machine tool market, how will the changing automotive needs affect the metalworking industry?

This article will take a closer look at trends in the automotive industry's shift to EVs, along with the impacts on the metalworking industry.

Trends in the Automotive Industry’s Shift to EVs

EV sales are accelerating globally, with America’s Tesla and China's BYD leading the market. The shift to electric vehicles from fossil fuel-based automobiles, including both gas-powered and diesel-powered automobiles, is also expected to pick up in Japan.

Based on trends in R&D and capital investments for equipment and infrastructure of Japanese domestic automakers, each automaker will likely focus their efforts on EVs.

Automotive parts comprise a large share of the machine tool market. As EVs gain in popularity, it is likely to greatly impact the manufacture of automotive parts such as engines and engine parts, electrical and electronic components, and steering equipment. Given the large share of automotive parts in the machine tool market, the related companies will have to respond to any change.

In particular, since engines and engine parts are almost completely unnecessary with complete BEVs, companies involved in the manufacturing of gasoline and diesel engines will be forced to transform their businesses.

Impacts of the EV Shift

Exactly what impact will the shift to EVs have on the metalworking industry?

In place of engines, EVs come with batteries and motors. While cutting features in the manufacturing process for engine parts on gas-powered automobiles, few elements in batteries and motors require machining. Given this, a change in capital investments for parts manufacturing is likely.

For example, compared to automotive and automotive parts manufacturing, a lower proportion of capital investments are devoted to metalworking machinery for industrial and other electrical machinery. In addition, the estimated price of machine tools used per automobile for gas-powered automobiles is roughly 15,000 yen. For EVs, this is expected to be nearly halved to roughly 8,000 yen.

In automotive manufacturing, the main components will shift from engines to batteries, motors, and inverters. In addition, in order to address the needs to extend the EV pain point of driving range and to increase quietness, the machine tool industry will need to align their measures with electrification, such as changing over to a course that will reduce vehicle weight.

Cut Parts Expected to Decrease Due to the EV Shift

Unlike gas-powered automobiles and their internal combustion engines, as the popularity of engineless EVs spreads, demand for key engine components can be expected to diminish greatly.

Cut parts will be heavily impacted by gigacasting. Gigacasting is a new technique for manufacturing a vehicle chassis, which is conventionally formed by joining numerous parts in many steps, as a single component with a single casting process. As it can be used to unify dozens of parts, some automakers have already introduced this process as a way to reduce costs.

Gigacasting is expected to dramatically reduce the workloads and iron used by press and mold manufacturers, as well as for in-house pressing, welding, and assembly processes. While gigacasting will help automakers improve their profitability, it will also make huge waves in production processes and supply chains.

Cut Parts Expected to Increase with the EV Shift

Meanwhile, some cut parts are expected to increase with the EV shift.

Increased Use of Semiconductors and Electronic Components for Autonomous Driving

Along with electrification, advances in IT technology in recent years have also made cars smarter. The number of electronic devices equipped on automobiles will continue to grow more as automobiles are equipped with advanced driver assistance systems (ADAS) with cameras and sensors to support driving, autonomous driving, infotainment features, telematics technologies, and more. The latest automobiles are loaded with more than 100 ECUs.

As any defects in these electronic devices could sway automobile safety, there is growing demand for parts manufacturing to have zero defects. Moving forward, companies working on electronic devices equipped on automobiles must also consider creating systems that fully prevent defects.

Motors and Batteries

While demand will decline for engine parts, demand is expected to increase for molding machine tools for motor manufacturing. This is because manufacturing motor core materials will require high-accuracy punching molds. In motor manufacturing, demand may increase for plastic working machines.

In terms of manufacturing for EV batteries, lithium-ion and otherwise, it is important to understand that more accurate micro machining is required for metal case presswork with a press and molding with machine tools. Demand should increase for machining centers, grinding machines, electrical discharge machines, and micro machining tools.

Reducers Going Mainstream

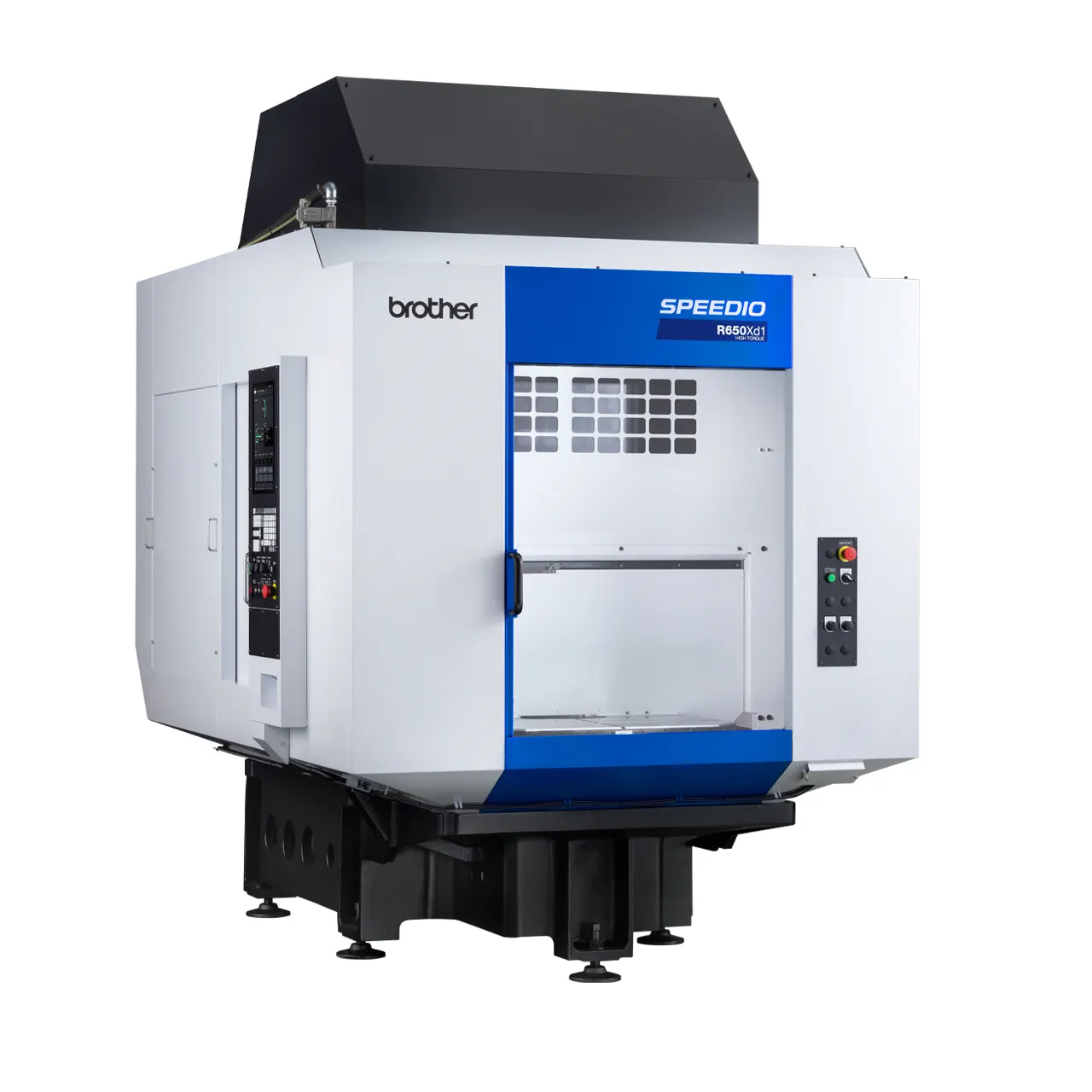

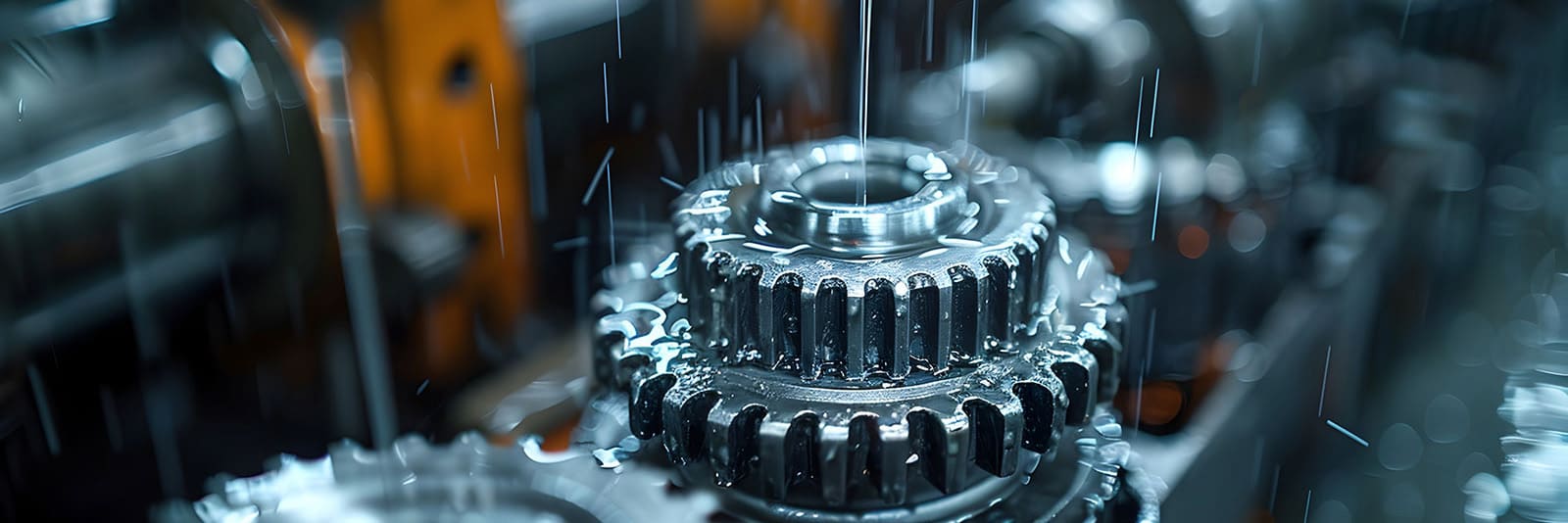

With the shift to EVs, reducers are expected to overtake conventional transmissions as the new norm. With their use of complex gearing and in efforts to reduce noise and vibration, manufacturing reducers takes high-accuracy gear machining.

More Light Metal Parts

One reason for the slow adoption of EVs is their short driving range compared to gas-powered automobiles. To extend EV driving range, it is important to reduce vehicle weight, such as by using aluminum or carbon fiber reinforced plastic (CFRP), a new lightweight, strong material.

Aluminum, which is lightweight and easy to process, is already widely used in automotive parts. Given the need to lighten vehicles, aluminum usage is likely to further expand in the future. Aluminum machining methods are also being re-examined, and more productive machine tools are expected to be developed.

In the Cutting Industry, Compete with Light Metal Parts

The global shift to EVs is certain to render some parts obsolete—chief among them, engines. In their place, new demand will emerge for motors, batteries, and reducers. In some cases, the number of components will even increase with electrical and electronic components.

In addition, with the need for weight reductions to increase driving range, demand for cutting aluminum alloys is expected to increase.

As automotive technology advances, automotive parts manufacturers will need to build systems that respond to new demands.

Author: Miyuki Takahashi

Editor: EGGO CO., LTD.

Related Articles

What Is Die Casting? And the Differences and the Relationship Between Die Casting and Cutting