What Is Simultaneous 5-Axis Machining? Overview and Advantages of Simultaneous 5-Axis Machining Explained

The evolution of machining technology in the manufacturing industry has been remarkable, and "simultaneous 5-axis machining" is one of the technologies that has become increasingly popular in recent years. It has features not found in 1- to 3-axis machining, and it offers advantages such as improved productivity and reduced manpower. So, how does simultaneous 5-axis machining differ from conventional machining methods, and exactly what manufacturing fields use it? This article will provide an overview of simultaneous 5-axis machining and explain its advantages, use cases, and points to note when considering introduction.

What Is Simultaneous 5-Axis Machining?

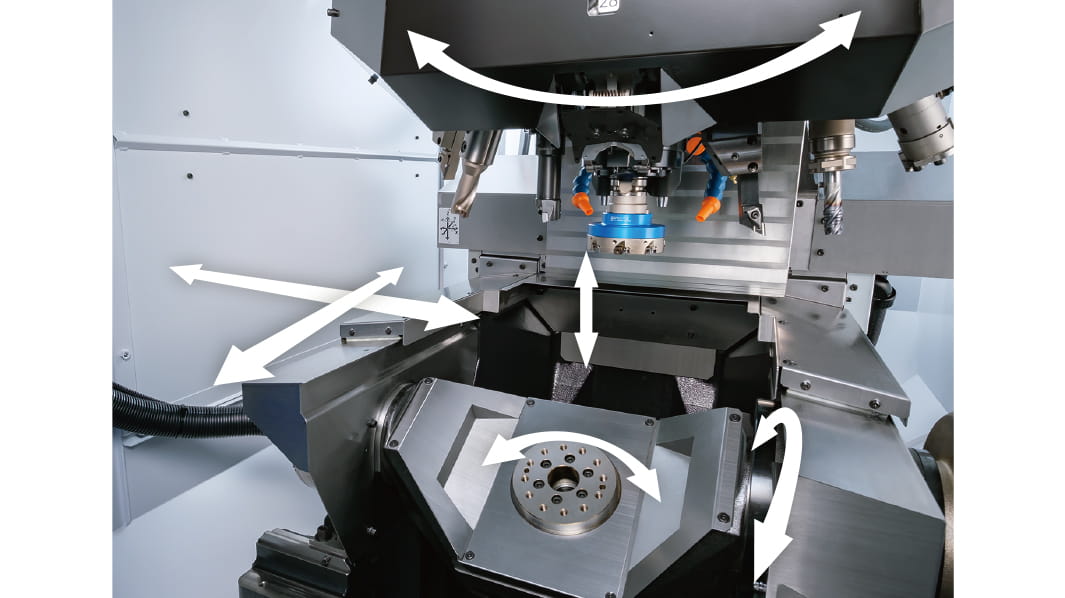

Simultaneous 5-axis machining is a technology in which the spindle and turret move along the X, Y, and Z axes while the rotation and tilt axes are controlled simultaneously. Operating these five axes simultaneously enables complex machining not possible with conventional 3-axis machining.

The image above shows the operational axes of a 5-axis machining center. Notice here that, in addition to the three axes for tool spindle movement, the workpiece mounting table also rotates and tilts. Simultaneous 5-axis machining involves cutting the workpiece as each axis moves simultaneously. Note that the rotation and tilt axes do not necessarily mean that the table moves. There are also 5-axis machining centers where the tool spindle turns and rotates (5-axis machining centers to be described later).

Simultaneous 5-Axis Machining vs. 3-Axis Machining and Indexing 5-Axis Machining

As the name suggests, 3-axis machining is machining performed based on three axes: Vertical, horizontal, and height. Whether the table moves or the tool moves will depend on the machine tool, but most any workpiece can be machined with 3-axis machining. However, in many cases, jigs and special tools must be used to adjust the tilt for complex products. In contrast, with 5-axis machining, the tool can be applied at the appropriate angle to the inclined surface, and undercuts can be performed without workpiece changeover.

Yet another machining method is called indexing 5-axis machining. Unlike simultaneous 5-axis machining, in this method a specific axis is fixed before machining begins. One or both of the rotation and tilt axes are fixed, and machining is performed by moving the three or four remaining axes simultaneously. Since the machining data is easier to create and cutting conditions easier to adjust than for simultaneous 5-axis machining, indexing 5-axis machining sees frequent use in the field.

Advantages of Simultaneous 5-Axis Machining

With its combination of precision and flexibility, simultaneous 5-axis machining offers companies many benefits. Here are the features and advantages of simultaneous 5-axis machining.

High Machining Flexibility

One of the greatest advantages of simultaneous 5-axis machining is its flexibility in machining. In addition to performing multi-face machining with a single setup, it is also suited to machining surfaces that curve in three dimensions, such as on propellers and fans. With their ability to make products of various shapes and sizes, another advantage of machine tools with simultaneous 5-axis machining capability is that they can be used for high-mix, small-lot production.

Improved Productivity

Simultaneous 5-axis machining can also be expected to improve productivity. Once a machining program is created, the tool will perform the machining automatically. As the tool can complete multiple processes for a single machining job, there is no need to reposition the workpiece for each and every step. This greatly reduces machining errors for high-quality, efficient production.

In addition, by cutting with an incline, machining can be performed at the optimal peripheral speed range, meaning that cycle times can be shortened by increasing cutting conditions.

Reduced Tool Wear

In 5-axis machining, the angle of contact between tool and workpiece can be adjusted appropriately by computer. For example, even in cases where the tool would have to be applied vertically in 3-axis machining, using 5-axis machining allows for the tool to be applied diagonally to the workpiece. This eliminates the zero point for peripheral speed and reduces tool wear. In addition, with simultaneous 5-axis control reducing the amount of tool protrusion, surface quality can also be improved.

Disadvantages of Simultaneous 5-Axis Machining

While simultaneous 5-axis machining does have numerous advantages, there are also disadvantages. For those considering deployment of a 5-axis machining center, it is important to understand both the good and the bad.

Costly to Deploy

The biggest bottleneck to deploying a simultaneous 5-axis machining center is the cost of deployment. Simultaneous 5-axis machining centers cost more than 3-axis machining centers, so the initial investment will inevitably be higher. Some companies that have never used a 5-axis machining center never take the plunge to deployment due to uncertainty over whether it will wind up being cost-effective.

Not Suitable for Roughing or Heavy-Duty Cutting

5-axis machining centers are especially suited to delicate work and advanced precision machining. Conversely, they are not well-suited to tasks such as roughing with great cutting depth or heavy-duty cutting using large tools. Thus, companies mainly engaged in such machining will need to consider 3-axis machining centers or other suitable machines.

Limited Workpiece Sizes

Given the relatively complex structure of 5-axis machining centers, the table tends to be smaller than those on 3-axis machining centers. As this can constrain machining of large parts and materials, it is important to consider what machine tools to deploy according to the size and type of product to be manufactured.

Example Simultaneous 5-Axis Machining Workpieces

Check out the videos below to see what can actually be made with simultaneous 5-axis machining.

M200Xd1-5AX 5-AXIS Machining (Youtube)

S500Xd1-5AX Impeller high speed machining (5-Axis machining) (Youtube)

M200Xd1-5AX 5-AXIS MACHINING Corner rest machining (Youtube)

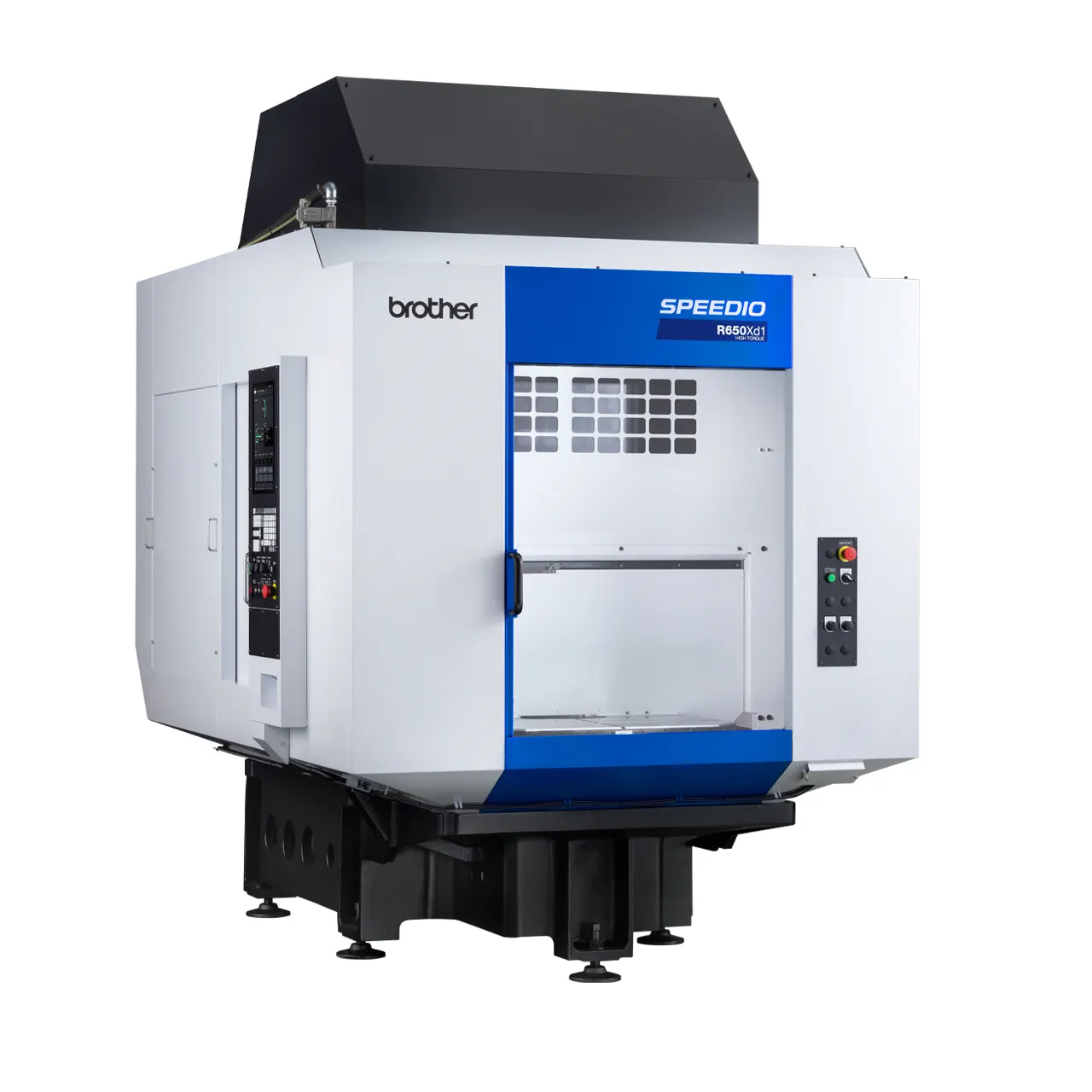

Types of Simultaneous 5-Axis Machining Centers and Key Points for Machine Tool Selection

Adopting a simultaneous 5-axis machining center will greatly increase the range of products that can be manufactured. But what kind of 5-axis machining center should you introduce? This section describes the main types of simultaneous 5-axis machining centers and key points to be aware of when introducing one.

To start with, simultaneous 5-axis machining centers can be broadly divided into the following three types. Each has its own characteristics, so choose the one that suits your company.

| Rotary tilting table (table rotates and tilts in addition to 3-axis movement) |

- Most models are smaller in size - The table moves significantly in the rotation and tilt axes |

|---|---|

| Rotary table and tilting head (table rotates and spindle tool tilts in addition to 3-axis movement) |

- Table does not tilt, allowing for stable machining even for heavier workpieces - Most models are horizontal machine tools - Good for deep cavity machining |

| Rotary tilting head (spindle tool rotates and tilts in addition to 3-axis movement) |

- Table does not have a rotation axis, allowing for machining of heavier workpieces - Most models have larger tables - Narrow range of motion for tilt and rotation axes |

When considering the introduction of simultaneous 5-axis machining centers, the first step is to have a clear image of what kind of product you will be making. From there, you can select a manufacturer and model, comparing the types and features of their 5-axis machining centers. If this will be your first 5-axis machining center, in addition to machine tool operability and programmability, also be sure to check that the manufacturer has a well-developed support system and after-sales service. Some machine tool manufacturers have showrooms, so it may be easier to imagine to actually pay them a visit. The manufacturers should also be able to directly provide detailed information on their 5-axis machining centers and advice on specific choices.

Inevitably, price will always be a bottleneck to 5-axis machining center deployment. It will be an investment of at least a few million yen, so plan your financing carefully. Various grants are also available for capital investments in new machine tools, so make the most of assistance available from the national and local governments.

Summary: Simultaneous 5-Axis Machining That Expands Manufacturing Possibilities

The greatest appeal of simultaneous 5-axis machining is its ability to machine even parts with complex shapes using fewer settings. The automation of work can be expected to shorten machining time, and fewer workpiece changeovers should improve accuracy. It will also greatly reduce human labor, which will lead to factory automation and manpower reduction.

In addition, with the ability to machine products not possible with 3-axis machining, introducing a 5-axis machining center should greatly expand your business potential. If you take full advantage of these benefits, you will be able to produce high-quality, efficient products and further increase your market competitiveness.

Author: Yuki Kobayashi

Editor: EGGO CO., LTD.

Related Articles

What Is Die Casting? And the Differences and the Relationship Between Die Casting and Cutting