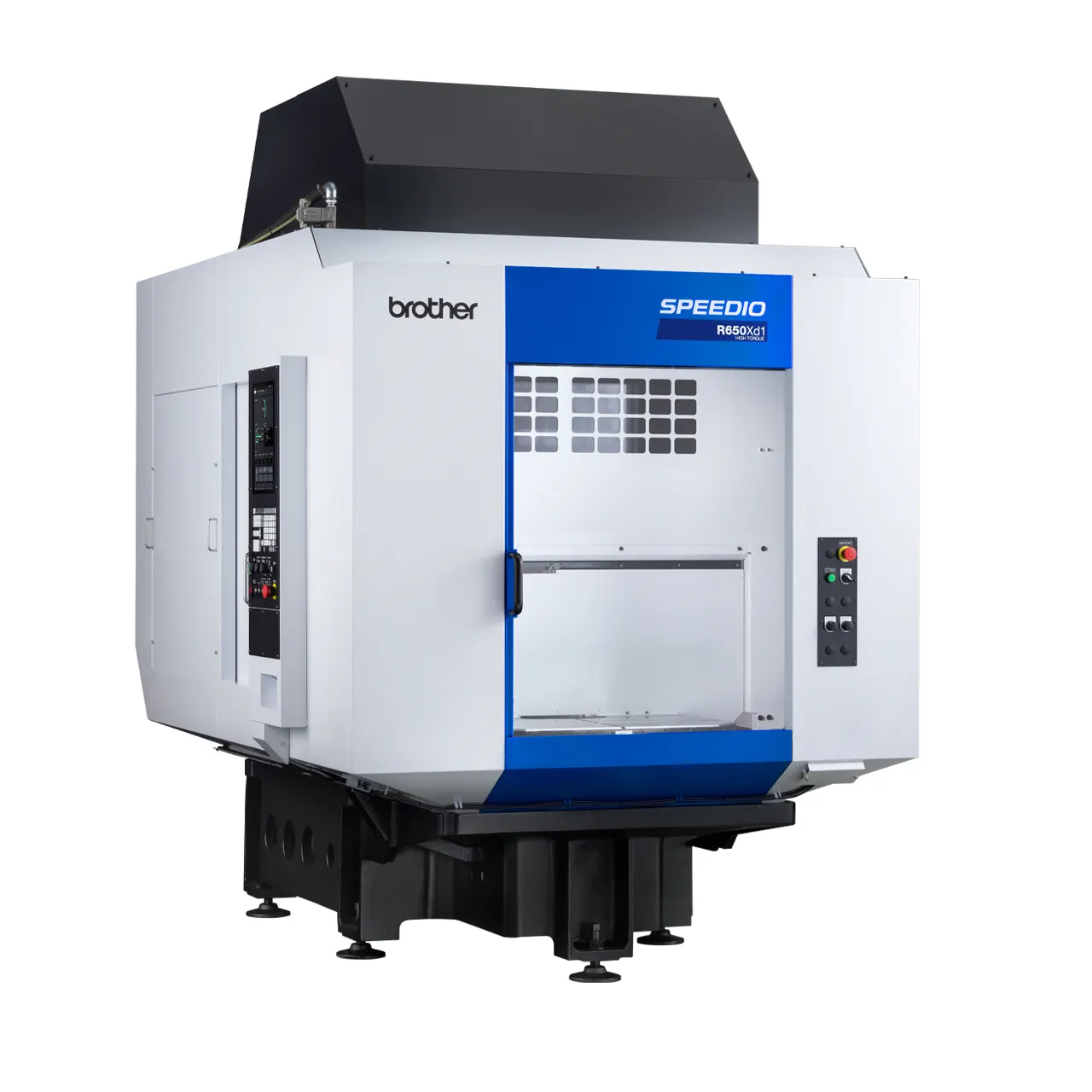

Disaster Strikes More Than Just People. Machine Tools and Natural Disaster

In recent years, natural disasters caused by extreme weather likely due to the impact of climate change have become more frequent around the world. In the manufacturing industry, disaster measures are important not only for people but also for machine tools. What measures should companies take after a disaster to quickly recover and resume production?

This article discusses the machine tool problems that may occur during natural disasters and the measures to take against natural disasters, as well as the recovery methods to use after a disaster.

What Happens if Machine Tools Are Damaged in a Natural Disaster?

Natural disasters may sometimes pose a risk to business operations. In recent years, more severe and frequent extreme weather that are likely due to the impact of climate change have resulted in a variety of natural disasters, including large typhoons, torrential rains, and lightning. Moreover, for earthquake-prone Japan, earthquake measures are also important.

When machine tools are damaged by such disasters, there may be production line stoppage due to power outages, equipment collapse due to earthquake shaking, damage due to water or mud, and other problems. Employees may also be at risk from malfunctioning equipment, electrical leaks, and other problems, requiring caution.

Disaster measures for machine tools are vital for the rapid recovery and resumption of operations in factories, as well as for the safety of employees.

Disaster Measures for Machine Tools

So how exactly should measures be taken against disasters? First, identify what kind of natural disasters may occur and the problems that may likely result from such disasters.

Refer to the methods given below and take the necessary measures for your company, with the aim of quickly resuming production after a disaster.

Earthquake Measures

There are three major types of measures that can be taken against earthquakes.

- Earthquake-proofing buildings

- Installing earthquake detectors and using a variety of systems on equipment and facilities

- Taking measures to prevent shelves and other indoor furnishing from falling over

Earthquake-proofing buildings is especially important for aging factories. Have your buildings checked and consider earthquake-proofing if necessary. Make use of grants and subsidies for earthquake-proofing factories, so that you can prepare for earthquakes while keeping costs relatively low.

As a first step toward earthquake-proofing your buildings, study the earthquake-proofing subsidy programs offered by local municipalities as well as the subsidy program offered by the Japanese national government.

Other effective measures include installing earthquake detectors on various equipment and facilities, and using systems that automatically stop machines when the seismic intensity exceeds a certain level. Systems that automatically stop machines in the event of an earthquake can also help prevent secondary disasters and ensure the safety of employees.

Furthermore, for shelves and facilities in factories and offices that may collapse during an earthquake, take measures to prevent them from falling over.

Measures Against Typhoons and Heavy Rains

During typhoons and heavy rains, equipment malfunction due to flooding and landslides, and downtime in operations due to power outages may occur. First, check your hazard map and identify the risks of typhoons and heavy rains.

For flooding and landslide risks, consider installing sandbags, waterstops, and waterproof doors. To protect against strong winds, it is a good idea to check windows, roofs, and doors for damage, ensure that they are sufficiently strong, and replace or maintain them.

In addition to these measures, it is also important to check the weather forecast frequently during periods when typhoons or heavy rains are likely to occur, and to take measures such as informing employees not to come to work and stopping factory operations when there is a possibility of a disaster.

Lightning Measures

Lightning measures are also important in factories that handle a variety of electronic equipment. It is a good idea to install surge protection devices (SPDs) that safely release lightning surges, in order to prepare for equipment malfunctioning and leakage currents.

SPDs can prevent equipment damage caused by overvoltage or overcurrent. Lightning measures are also effective in preventing secondary disasters such as fires and accidents caused by leakage currents.

Recovery Methods After a Disaster

Even with these measures in place, there is still a chance that a disaster may occur. However, factories that have measures in place to deal with natural disasters can expect a shorter time for recovering from disaster. Follow these steps to quickly resume production after an actual disaster.

Check the Safety of Employees

Employees are essential for resuming production and continuing business after a disaster. The safety of employees and their families must be checked first, and their individual situations confirmed.

Check the Damage Inside Factories and Offices

Check the damage of each facility and equipment and implement measures to prevent damage from spreading, in order to prevent secondary disasters such as accidents caused by leakage currents.

Check and Share Information on the Damage of Relevant Companies

Contacting business partners and other relevant companies early, and checking on their individual safety and damage status are also important. At the same time, inform them of your company's damage status and share information with each other.

Calculate the Time and Cost Required for Recovery

After checking on the damage status, calculate the time and cost required to resume production. Next, create a budget plan that includes the required costs for recovery and identify the resources required.

Prepare Resources to Resume Production and Provide Notification of the Resumption of Business Operations

On-site personnel cleans up inside the facilities and makes the necessary preparations for resuming business operations. If building or equipment repairs are necessary, contact construction companies or manufacturers and order the repairs. Management prepares the necessary funds based on the budget plan. Once recovery is complete, notify all relevant companies of the resumption of business operations.

Establishing a Secure System Even During Emergencies

Measures against natural disasters, which have been increasing in recent years, are essential from the perspective of business continuity. The services provided by the manufacturer cover everything from regular maintenance to emergency repairs.

We recommend that you not only take safety measures for your employees, but also establish a system that enables the quick resumption of business even during a disaster through disaster measures for various facilities and equipment.

Author: Miyuki Takahashi

Editor: EGGO CO., LTD.

Related Articles

What Is Die Casting? And the Differences and the Relationship Between Die Casting and Cutting