When to Update Your Machine Tools

Machine tools are so important that they can be said to be the engine running the manufacturing industry. When used for many years, however, tools will progressively deteriorate, and they will gradually fail more often. More frequent breakdowns could also affect production planning. This article will explain the timing for when to upgrade machine tools. It will also describe the average service life of machine tools, how to extend it, and more, as well as the judgment criteria for whether to repair or replace.

Service Life of Machine Tool Equipment and the Need for Upgrading

Generally speaking, the service life of a machine tool refers to the period during which the equipment performs consistently and can be operated safely. While service life may vary depending on the equipment type and usage, in the case of machine tools, 30 years or more is not uncommon with proper maintenance.

Basically speaking, however, parts will wear and deteriorate over the years, and equipment failures will gradually increase. If a machine tool reaches the point of being unrepairable or failures become too frequent, it will have reached the end of its service life. Using aging machine tools not only increases the risk of failure, but can also lead to reduced performance. What's more, equipment manufactured under old technical standards may not meet current environmental and safety standards. For these reasons, machine tools must be upgraded appropriately according to their condition.

Equipment is mainly upgraded in one of two ways: repairing and replacement. The decision of whether to repair equipment and continue using it or to replace it with a new one will likely depend on the machine tool's condition, your company's track record, and your trend of customer orders. Although repair is often the cheaper option, introducing the latest in machinery will often lead to reduced power consumption and improved productivity. Thus, it is important to make a comprehensive judgment on whether to repair or replace from a long-term perspective.

Appropriate Equipment Upgrade Timing

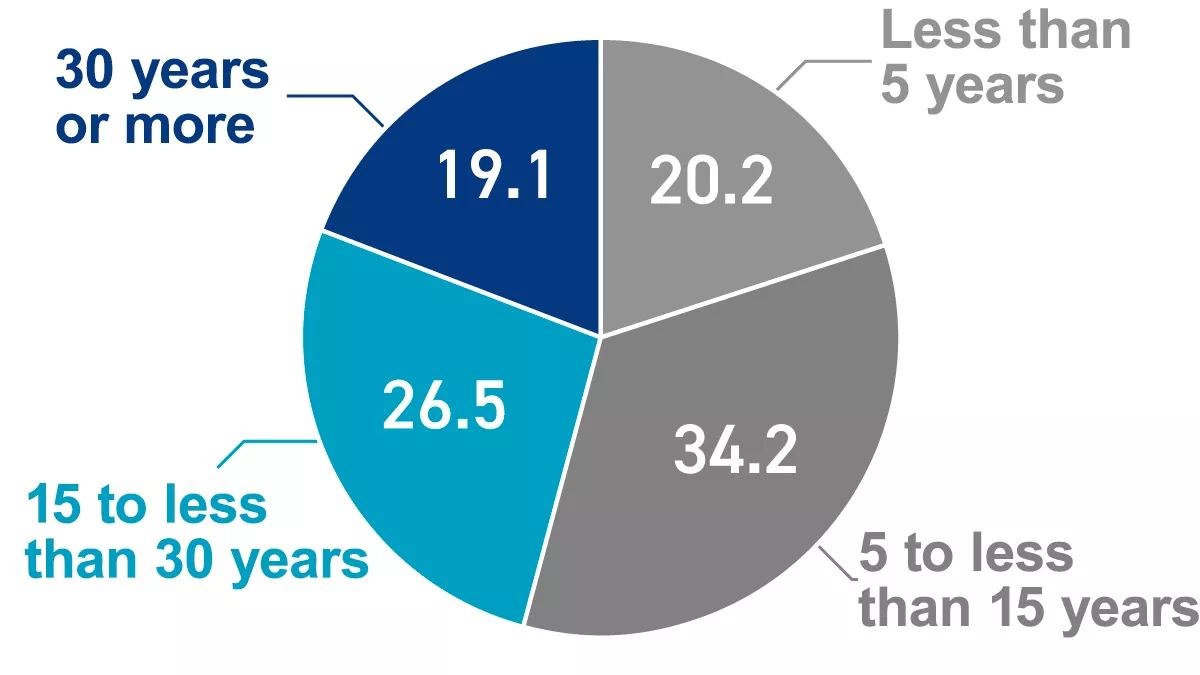

According to the 2018 Survey of Production Equipment Ownership Period, conducted by the Japan Machinery Federation, more than 40% of production equipment has been in use for 15 or more years. With nearly 20% of equipment in use for 30 or more years, the practical service life of production equipment can be placed at 15 to 30 years.

Specific indicators for timing when to upgrade your equipment include return on investment (ROI), total operating time, and failure rate. Assess whether an equipment upgrade makes sense financially based on the payback period and equipment operating time.

While aging equipment is trending up in recent years, little by little, upgrades are also happening. The Survey of Production Equipment Ownership Period mentioned above also shows the percentages of ownership period over time.

Comparing with the 2013 version of the same survey, the percentage of production equipment in service for 15 or more years has increased, and so has that for equipment owned for less than 5 years. This suggests a growing bifurcation in the industry between companies that continue to use aging equipment and those active in their capital investments. Meanwhile, when asked whether they had a capital investment plan for the next three years, roughly 62% of respondents said that they had a specific capital investment plan. This indicates that many companies are discussing additional or new production facilities.

How to Extend Service Life of Machine Tools

How can you both extend the service life of your production equipment and maintain product quality? Here are some ways to maximize the service life of your equipment. Each of these methods to extend machine tool life is simple and basic. However, these everyday practices will lead to efficient operation and extend the service life of your equipment.

Routine Maintenance

Regular inspections and maintenance of equipment are the most basic means of extending its service life. Replacement of worn parts and early detection of abnormalities and strange noises can prevent major failures. In addition, as dirt and foreign matter entering the equipment can degrade performance, regular cleaning and filter replacement are also essential tasks to extend the service life of your equipment.

Usage Condition Optimization

Using equipment beyond its specifications and capabilities may result in excessive loads and shortened service life. As such, following the usage and operating conditions recommended by the manufacturer can extend the service life of your machinery. Furthermore, conditions such as humidity, temperature, and vibration in the installed location of the machine tool will also affect its performance and service life. Operating under appropriate conditions can help to keep mechanical deterioration in check.

Failure History Management

It is also a good practice to track equipment failures and parts replacement. Fixed point observation of the time from one failure to the next will serve as a criterion for judging when to upgrade the equipment. Also, the mean time between failures (MTBF) can be useful in preventing and predicting machine tool failures. This indicator is calculated by dividing total operating time by the total number of failures. For example, if there have been 2 total failures over a total operating time of 1,000 hours, the MTBF is 500 hours (= 1,000 / 2).

Benefits of Introducing New Machine Tools

If machine tools are getting older or their failure rate is increasing, replacement should also be considered. Introducing new equipment can also serve to improve productivity and ensure quality. In addition, most modern machine tools are highly energy-efficient, reflecting a focus on environmental considerations and cost reduction. Long-term, it can also be expected to reduce energy costs.

According to results from the Survey of Production Equipment Ownership Period, conducted by the Japan Machinery Federation, many companies that have introduced new equipment have experienced benefits including increased production volume and productivity, manpower reductions, and energy saving.

Q. To what extent did capital investment benefit you in these specific ways?

(Companies with production machinery less than 3 years old, N = 302)

| Improvement rate | Increased production volume | Reduced production time per unit |

Manpower reduction | Resource/energy saving |

|---|---|---|---|---|

| 0% to less than 5% | 7.3% | 8.9% | 9.3% | 13.2% |

| 5% to less than 10% | 10.6% | 7.3% | 7.0% | 5.6% |

| 10% or more | 52.3% | 42.4% | 28.5% | 16.2% |

Key Points on Equipment Upgrading and Capital Investment

When upgrading your equipment, keep the following points in mind in your considerations and purchasing.

[Key points for equipment upgrades]

Clarify the objectives for introduction: It is important to clarify the objectives for introducing new equipment and to choose equipment that suits that objective.

Consider total cost of ownership: The total cost performance must be evaluated, including the cost of operation and maintenance as well as equipment installation.

After-sales support: It is important to select a manufacturer with extensive after-sales support, considering what is supported and their warranty period.

Employee training: With the introduction of new equipment, operating and maintenance procedures may also change. This creates opportunities for employees to be trained and acquire the knowledge and skills to get the most out of this equipment.

The introduction of new equipment is an important management decision given the significant investment involved. Thus, it is important to establish a firm capital investment plan and assess whether capital investments are appropriate. This should be done before raising funds and, depending on the circumstances, considering what grants are available.

Equipment Upgrades as a Direct Investment in Company Growth

While there are exceptions, machine tools are generally said to have a service life of about 15 to 30 years. The more a machine tool is used, the more it will wear out and deteriorate, so perform all routine maintenance to detect abnormalities early and prevent failures. And if equipment failures are frequent, consider replacing it. In today's competitive market, equipment upgrades are a pivotal step in boosting company productivity and efficiency. Introducing new equipment will make your company more competitive, so take the business conditions and market trends into account while considering whether an equipment upgrade works for your company's situation.

Author: Yuki Kobayashi

Editor: EGGO CO., LTD.

Related Articles

What Is Cutting Speed? Calculation Formula and How to Determine Cutting Conditions