SPEEDIO M140X1

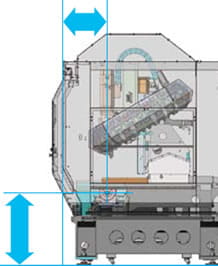

- Travels (mm): X: 200 Y: 440 Z: 305

- Travels (A, C) (deg.): A: 5 to -95, C: 360

- Max. spindle speed (min-1): 10,000/ (Optional) 16,000

- Tool storage capacity(pcs.): 22

- Max. turning spindle speed (min-1): 2,000

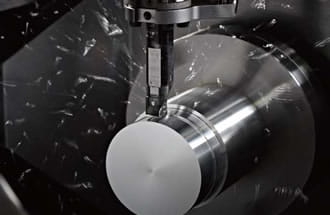

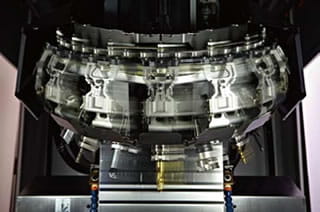

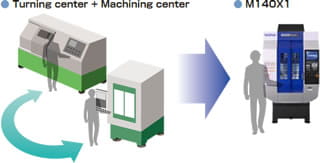

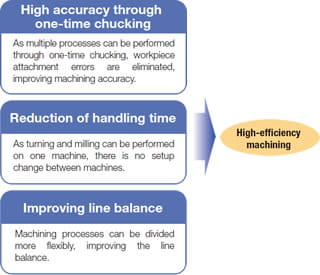

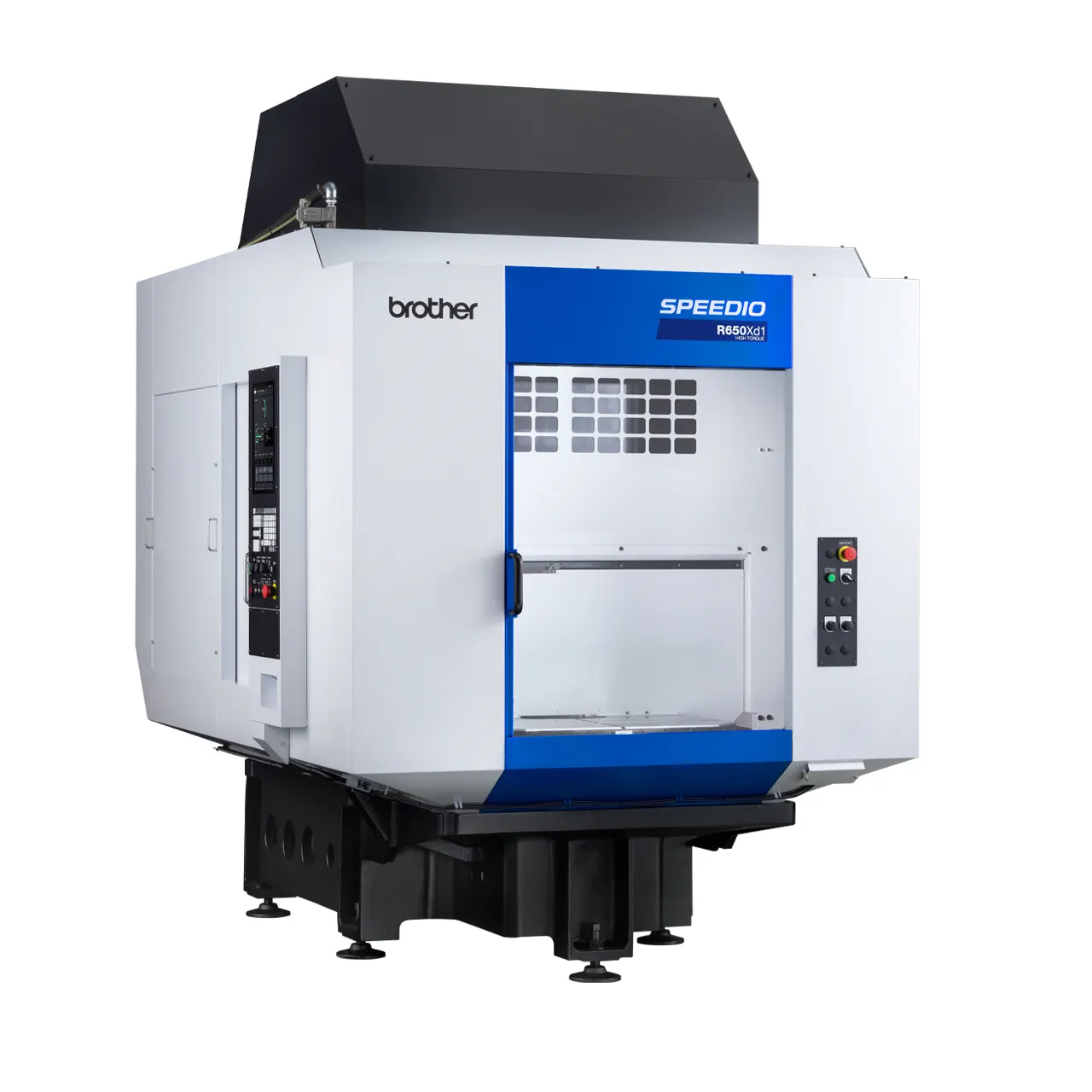

The best for process concentration of mass-production part processing. The compact multi-tasking machines to which the lathe-turning function was added. We ended sale of this product. The information on the telephone about repair or maintenance of product should have a look "Distributors" page.

Information

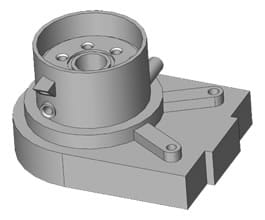

Overview

Start/stop time

0.2s

Chip to Chip

1.4s

Max. torque

40Nm

Max. output

18.9kW

Max. torque

55Nm

Max. output

8.7kW

From front opening to table

490mm

From floor to table

795mm

Advanced usability

The machine is equipped with the new CNC-C00 controller, greatly improving processing capabilities and enhancing functions and usability.

Operability

Equipped with 'shortcut' keys to quickly open the desired screen and 'sub folder' to make program management easier, in addition to the USB memory interface, menu programming and tap return function.

Network function

High capacity program data can be transferred via Ethernet at high speed. The simple production monitoring function is also available allowing you to monitor the machine's status.

Machining support functions

Equipped with machining support functions, such as torque waveform display,high accuracy mode, and heat expansion compensation system.

Maintenance functions

Equipped with motor insulation resistance measurement, operation log, and maintenance notice function.

System capacity

Standard equipped with PLC. Input and output points can be extended to up to 1024 points each ( Optional ).

Specifications

Product Specification

M140X1

Max. spindle speed

10,000/ (Optional) 16,000

Travels

X: 200 Y: 440 Z: 305 A(deg.):5 to -95 C(deg.):360

Tool storage capacity

22

Rapid traverse rate (XYZ-area)

50 x 50 x 50

Indexing feedrate(A,C)

A:60 C:200

Required Floor Space

1,280 x 3,641

Coolant Through Spindle(CTS)

Optional

| Item | M140X1 | ||

|---|---|---|---|

| CNC Unit | CNC-C00 | ||

| Travels | X axis [mm (inch)] | 200 (7.9) | |

| Y axis [mm (inch)] | 440 (17.3) | ||

| Z axis [mm (inch)] | 305 (12.0) | ||

| A axis [deg.] | 5 - -95 | ||

| C axis [deg.] | 360 | ||

| Table | Work area size [mm( inch )] | D140 (D5.5) | |

| Shape of table top | In compliance with table nose No.5 of ISO702-4 (JISB6109-2) | ||

| Max.loading capacity (uniform load) [kg ( lbs)] | 40 (88.2) | ||

| Maximum table load inertia [kg・m2(lb・inch2)] | 0.32 (1093) | ||

| Spindle | Spindle speed [min-1] | 10 - 10,000 | |

| Speed during tapping [min-1] | MAX. 6,000 | ||

| Tapered hole | 7/24 tapered No.30 | ||

| Coolant Through Spindle (CTS) | Optional | ||

| Turning spindle | Max. spindle speed [min-1] | 2,000 | |

| Feed rate | Rapid traverse rate ( XYZ-area ) [m/min(inch/min)] | 50 × 50 × 50 (1,969 × 1,969 × 1,969) | |

| Cutting feed rate [mm/min(inch/min)] | X,Y axis : 1 - 10,000 (0.04 - 394) Z axis : 1 - 20,000 (0.04 - 787) | ||

| Indexing feedrate (A and C) [min-1] | A axis 60 C axis 200 | ||

| ATC unit | Tool shank type | MAS-BT30 | |

| Pull stad type*4 | MAS-P30T-2 | ||

| Tool storage capacity [pcs.] | 22 | ||

| Max. tool length [mm( inch )] | 200 (7.9) | ||

| Max. tool diameter [mm( inch )] | 80 (3.1) | ||

| Max. tool weight [kg ( lbs )]*1 | 3 (6.6) | ||

| Tool selection method | Random shortcut method | ||

| Tool change time*5 | Tool To Tool [sec.] | 0.9 | |

| Chip To Chip [sec.] | 1.4 | ||

| Electric motor | Main spindle motor (10 min/continuous) [kW]*2 | 10.1/6.7 | |

| Axis feed motor [kW] | X,Y axis 1.0 Z axis 1.8 A axis 1.8 | ||

| Turning spindle motor [kW] | 4.2 | ||

| Power source | Power supply | AC V±10%, 50/60Hz±1Hz | |

| Power capacity (continuous) [kVA] | 9.5 | ||

| Air supply | Regular air pressure [MPa] | 0.4 - 0.6 (recommended value : 0.5MPa)*6 | |

| Required flow [L/min] | 130 | ||

| Machine dimensions | Height [mm (inch)] | 2513 (98.9) | |

| Required floor space [mm (inch)] | 1,280 × 3,641 (50.4 × 144.7)[including chip conveyor] | ||

| Weight [kg (lbs)] | 2,370 (5,226) | ||

| Accuracy*3 | Accuracy of bidirectional axis positioning ( ISO230-2:2006 ) [mm (inch)] | 0.006 - 0.020 (0.00024 - 0.00079) [X,Y,Z] 28 sec or less [A,C] | |

| Repeatability of bidirectional axis positioning ( ISO230-2:2006 ) [mm (inch)] | Less than 0.004 (0.00016) [X,Y,Z] 16 sec or less [A,C] | ||

| Standard accessories | Instruction Manual (1 set), anchor bolts (4 pcs.), leveling bolts (4 pcs.) | ||

- *1 Actual tool weight differs depending on the configuration and center of gravity.The figures shown here are for reference only.

- *2 Spindle motor output differs depending on the spindle speed.

- *3 Measured in compliance with ISO standards and Brother standards.

- *4 Brother specifications apply to the pull studs for CTS.

- *5 Measured in compliance with JIS B6336-9 and MAS011-1987.

- *6 Regular air pressure varies depending on the machine specifications, machining program details, or use of peripheral equipment. Set the pressure higher than the recommended value.

| CNC model | CNC-C00 | |

|---|---|---|

| Control axes | 5axes (X,Y,Z,A,C) | |

| Simultaneously controlled axes | Positioning | 5axes ( X,Y,Z,A,C) |

| Interpolation |

|

|

| Least input increment | 0.001mm, 0.0001inch, 0.001 deg. | |

| Max.programmable dimension | ±9999.999mm, ±999.9999inch | |

| Display | 12.1-inch color LCD | |

| Memory capacity | Approx.100 Mbytes (Total capacity of program and data bank) | |

| External communication | USB memory interface, Ethernet, RS232C 1ch | |

| No.of registrable programs | 4,000 (Total capacity of program and data bank) | |

| Program format | NC language * Conversation language not available. | |

| Standard NC functions |

|

|

| Optional NC functions |

|

|

- * When program size is bigger than 2 Mbytes. machine works with extended memory operation.

- * Ethernet is a trademark or registered trademark of XEROX in the United States.

- *1: Measuring instrument needs to be prepared by users.

Please ask about an option.

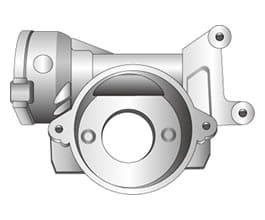

Example