CNC Tapping Center TC-32BN QT FT

Contact DistributorCNC Tapping Center TC-32BN QT FT

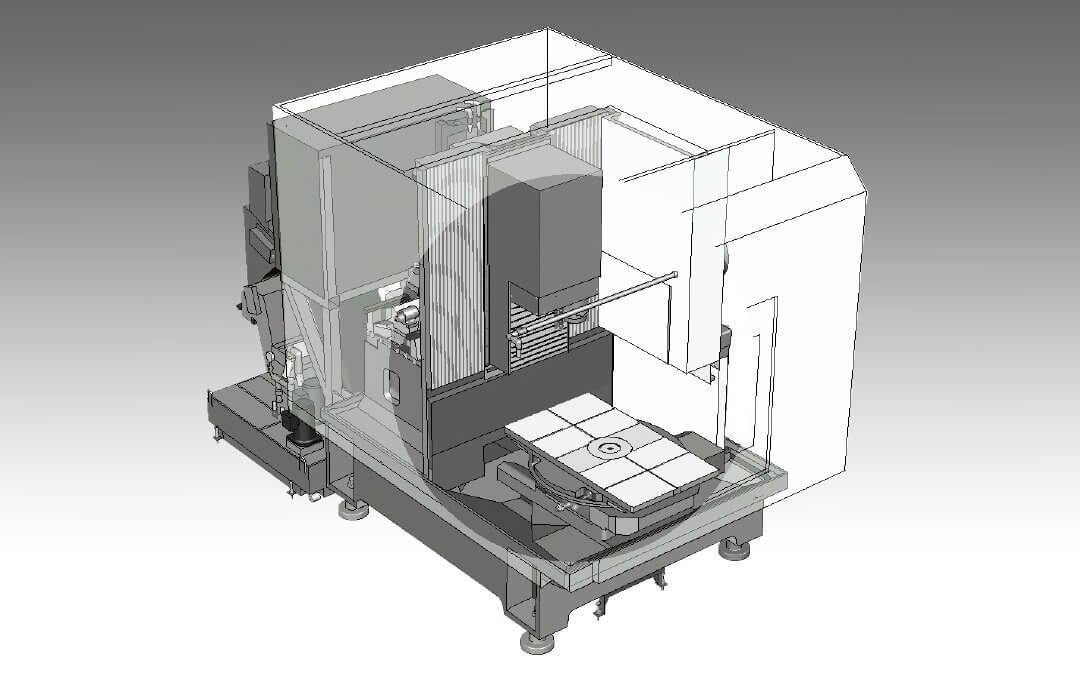

- Travels (mm) X: 550 Y: 400 Z: 415

- Max. spindle speed (min-1): 12,000/ (Optional) 16,000

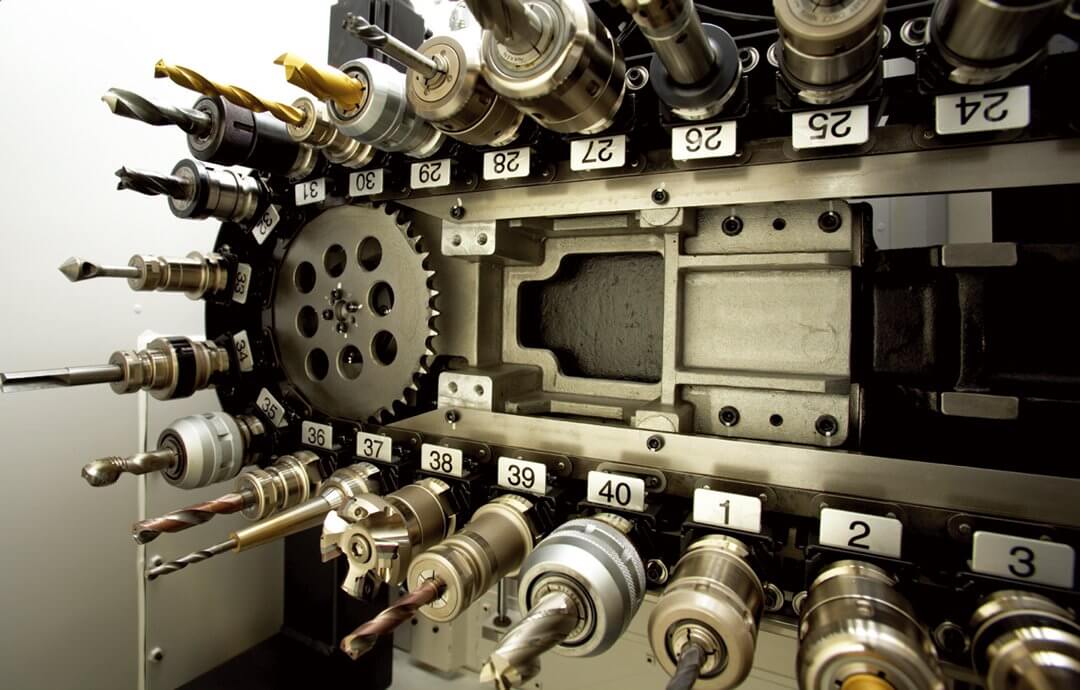

- Tool storage capacity (pcs.): 26(+1) / 40(+1)

High-performance column traverse machine with leading edge #30 machining capabilities and 40-tool storage capacity to achieve high productivity

Information

Overview

Specifications

Product Specification

| item | TC-32BN QT/FT |

|---|---|

| Max. spindle speed | 12,000min-1 16,000min-1(Optional) |

| Travels | X:550mm Y:400mm Z:415mm |

| Tool storage capacity | 26pcs.(+1) / 40pcs.(+1) |

| Rapid traverse rate (XYZ-area) | 70m/min × 70m/min × 70m/min |

| Required floor space | [QT]1,890mm × 3,669mm [FT]1,890mm × 3,103mm |

| Coolant Through Spindle(CTS) | Optional |

| item | TC-32BN QT | TC-32BN FT | ||||

|---|---|---|---|---|---|---|

| 12,000min-1 specifications | 16,000min-1 specifications | 12,000min-1 specifications | 16,000min-1 specifications | |||

| CNC unit model | CNC-B00 | CNC-B00 | ||||

| Travels | X axis [mm(inch)] | 550 (21.7) | 550 (21.7) | |||

| Y axis [mm(inch)] | 400 (15.7) | 400 (15.7) | ||||

| Z axis [mm(inch)] | 415 (16.3) | 415 (16.3) | ||||

| Distance between table top spindle nose end [mm(inch)] | 645 (25.4) | 645 (25.4) (standard),

865 (34.1) (low) |

||||

| Table | Work area size [mm(inch)] | 600 x 425 (23.6 x 16.7) (one side) | 800 x 400 (31.5 x 15.7) | |||

| Max. loading capacity (uniform load) [kg(lbs)] | 200 (441) (one side) | 600 (1323) | ||||

| Max. turning diameter [mm(inch)] | 1,200 (47.2) | - | ||||

| Table positioning time [sec.] | 3.4 / 180deg. | - | ||||

| Table chage repeatability [mm(inch)] | 0.01 (0.0004) (table center) | - | ||||

| Spindle | Spindle speed [min-1] | 12 - 12,000 | 16 - 16,000 | 12 - 12,000 | 16 - 16,000 | |

| Speed during tapping [min-1] | MAX.8,000 | MAX.8,000 | ||||

| Tapered hole | 7/24 tapered #30 *9 | 7/24 tapered #30 *9 | ||||

| Feed rate | Rapid traverse rate X x Y x Z axes [m(inch)/min] | 70 x 70 x 70 (2,756 x 2,756 x 2,756) | 70 x 70 x 70 (2,756 x 2,756 x 2,756) | |||

| Cutting traverse rate [mm(inch)/min] | 1 - 20,000 (0.04 - 787.4) | 1 - 20,000 (0.04 - 787.4) | ||||

| ATC unit | Tool shank type | MAS-BT30*9 | MAS-BT30*9 | |||

| Pull stud type*8 | MAS-P30T-2 *9 | MAS-P30T-2 *9 | ||||

| Tool storage capacity [pcs.]*1 | 26(+1) / 40(+1) | 26(+1) / 40(+1) | ||||

| Max. tool diameter [mm(inch)]*2 | 0 - 30 (0 - 1.2) / D46 (1.8) , 30 - 200 (1.2 - 7.9) / D55 (2.2) (Large tool D125 (4.9)) |

|||||

| Max. tool length [mm(inch)] | 200 (7.9) | 200 (7.9) | ||||

| Max. tool weight [kg(lbs)]*3 | 3.5 (7.7) | 3.5 (7.7) | ||||

| Tool selection | Double arm method (random shortcut) | Double arm method (random shortcut) | ||||

| Tool change | Tool To Tool: 0.9sec(BT)*10

Chip To Chip: 2.0sec(BT)*10 |

|||||

| Electric motor | Main spindle motor (10 min / continuous) [kW]*4 | 11/ 6 | 10/ 7.3 | 11/ 6 | 10/ 7.3 | |

| Feed spindle motor [kW] | 1.3 (X, Y, Z) | 1.3 (X, Y, Z) | ||||

| Power source | Power supply | AC 3Φ, 50 / 60Hz 1Hz | AC 3Φ, 50 / 60Hz 1Hz | |||

| Power capacity [kVA]*5 | 16 (Max. 32) | 18 (Max. 37) | 16 (Max. 32) | 18 (Max. 37) | ||

| Air supply | Working air pressure | 0.4MPa - 0.6MPa | 0.4MPa - 0.6MPa | |||

| Required flow*6 | 120 L/min (at atmospheric pressure) | 120 L/min (at atmospheric pressure) | ||||

| Machining dimensions | Machine height [mm(inch)] | 2,360 (92.9) | 2,360 (92.9) | |||

| Required floor space (with control unit door open)[mm(inch)] | 1,890 x 3,669 (74.4 x 144.4) | 1,890 x 3,103 (74.4 x 122.2) | ||||

| Machine weight (including control unit splash guard)[kg(lbs)] | 4,600 (10,143) | 4,400 (9,702) | ||||

| Accuracy*7 | Positioning accuracy [mm(inch)] | 0.005 / 300 (0.0002 / 11.8) | 0.005 / 300 (0.0002 / 11.8) | |||

| Repeatability [mm(inch)] | ±0.003 ( ±0.00012) | ±0.003 ( ±0.00012) | ||||

- *1 When all tools are small tools (D55mm or less).

- *2 The tool storage capacity, tool change time, etc., will vary when using large tools. The tool change time varies depending on the spindle type.

- *3 Actual tool weight varies according to the configuration and center of gravity; The figures shown here are for reference only.

- *4 Spindle motor output differs depending on the spindle speed.

- *5 These include 0.9 KVA for chip conveyor and 4.2 KVA for high-pressure coolant.

- *6 The required flow rate listed is the total flow rate when using the spindle air blast and coolant valve.

- *7 Measured in compliance with JIS B6201-1987.

- *8 Brother spec. is applied to pull stud for CTS.

- *9 Please contact Brother for details of HSK and NC5 types.

- *10 This is value of BT spec.

| Model | CNC-B00 | |

|---|---|---|

| Control axes | 7 axes ( X, Y, Z, 4 additional axes) | |

| Simultaneously controlled axes | Positioning | 5 axes ( X, Y, Z, A, B) |

| Interpolation |

|

|

| Least input increment | 0.001 mm, 0.0001 inch, 0.001 deg. | |

| Max. programmable dimension | ±9999.999mm 999.9999inch | |

| Display | 12.1-inch color LCD | |

| Program capacity | Approx. 5,000 m (Approx. 2 Mbytes) | |

| External communication | USB Interface, RS232C 1ch(9Pin), Ethernet | |

| No.of registrable programs | 1,024 | |

| Program format | NC language, conversation (changed by parameter), conversion from conversation program to NC language program available | |

| NC function |

|

|

- * Functions with (NC) and (conv.) are available only for NC language programming and conversational programming respectively.

Please ask about an option.

Example

For machining industries in Automotive parts

For machining industries in Motor cycle parts

Support

Reviews

Suitable with

Machine Tools Lineup

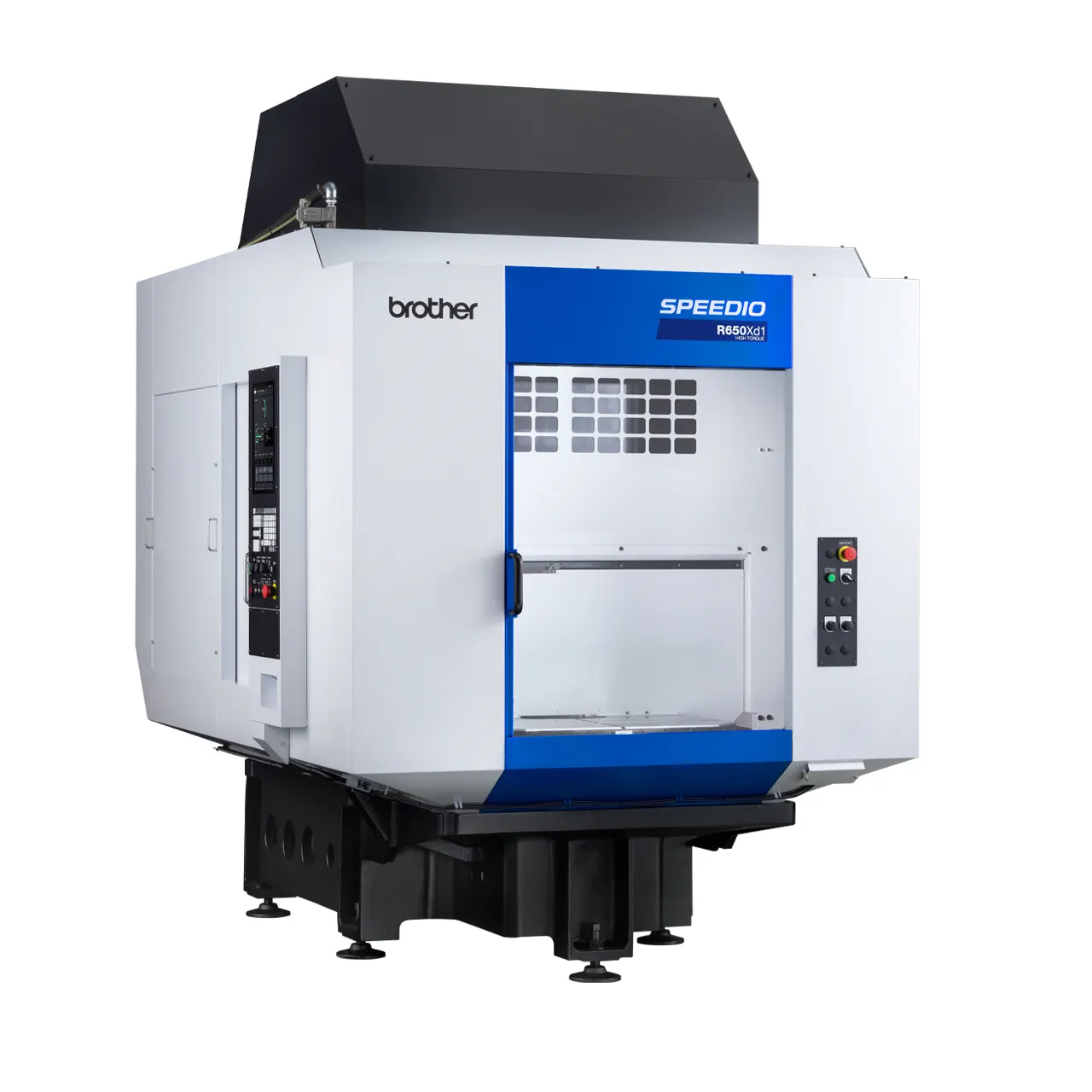

Compact machining center SPEEDIO

Horizontal Compact Machining Center

Multi-Tasking Machine SPEEDIO