In-Depth Explanations on the Mechanism, Advantages and Disadvantages, Performance, and Features of Horizontal Machining Centers

The horizontal machining center is a machining center with a horizontal tool spindle. It can cut workpieces from the side and complete various machining methods with a single machine. As work can be automated once a program is created, introduction will lead to productivity improvement even for complex processes.

This article will provide an in-depth explanation on horizontal machining centers. It will cover everything from mechanical structure and the history of the machining center to the unique advantages of horizontal machining centers.

What Is a Horizontal Machining Center? How It Works

A machining center is a machine tool based on the milling machine that is used in a wide range of fields, from light industry to heavy industry. Machining centers are categorized into several types by their structure, with a horizontal machining center being a machining center with its tool spindle set horizontal to the ground. To start, here is some basic knowledge on horizontal machining centers.

What Is a Horizontal Machining Center?

Horizontal machining centers are machine tools used mainly for machining of metal products with the tool spindle positioned horizontally. As they are based on the milling machine, they use a rotating tool to cut the workpiece into the desired shape. Unlike universal milling machines, which are operated manually, the horizontal machining center comes with features such as numerical control (NC) and an automatic tool changer (ATC) to make cutting more efficient.

The horizontal machining center consists of the following parts:

Tool magazine:

A part that holds multiple cutting tools and automatically changes the tool according to program instructions

Spindle:

The part to which the cutting tools attach. During machining, rotates at high speed for cutting

Table:

The part that secures the workpiece, and as needed, adjusts its position

Bed:

Serves as the base of the machining center, and suppresses vibrations and deviations that occur during machining

Column:

The part that supports the spindle and tool magazine, extending perpendicular to the ground

Background of Horizontal Compact Machining Center Development

The first machining centers date back to around 1960 in the United States. The Milwaukee Matic II, developed by Kerney & Trecker Co., is said to be the origin of the machining center. It had a horizontal spindle, making it a horizontal machining center. While there were NC machine tools that predate it, what made the Milwaukee Matic so revolutionary was its 30-tool magazine and ability to change tools automatically.

Meanwhile, machining centers were also being developed in Japan. The first Japanese machining center is recorded as a machine tool with a storage capacity of 25 tools, manufactured by Hitachi, Ltd. in 1964. During Japan's high economic growth period, domestic manufacturers were all focused on the development of machining centers, riding the wave of industrialization. As tool changing speed and machining accuracy increased, Japan grew into a machine tool powerhouse. In 1982, it surpassed the United States as world leader in machine tool production.

According to the Yearbook of Current Production Statics: Machinery, production volume of machining centers in 1985 was about 13,000 units. Production volume has increased steadily since the 1990s, reaching nearly 20,000 units in 2020.

Also, in recent years, machining centers have progressively gotten smaller. The market has transitioned from the age of mass production and mass consumption to high-mix, low-volume production, and models that achieve space savings with high accuracy and high productivity have become the norm.

Difference From Other Machining Centers

Machining centers are classified into different types according to their configuration and structure. Let's take a look at what differentiates horizontal machining centers from vertical and gantry machining centers.

Horizontal Machining Centers vs. Vertical Machining Centers

Vertical machining centers have the spindle and tool oriented vertically. With the tool positioned above the workpiece, these machining centers are suited to cutting the top surface of the workpiece. Their production volume is greater than that of horizontal and gantry machining centers, and they are widely used by small and medium-sized businesses as well as large-sized business.

Vertical machining centers are generally considered to be easy for workpiece setup, but they are also susceptible to chip buildup.

Horizontal Machining Centers vs. Gantry Machining Centers

A gantry machining center, as its name suggests, is a machining center with a double column, bridgelike frame. These are well-suited to machining large, heavy workpieces and, depending on the machine size, come in types that can even process products larger than 10 m. Gantry machining centers are used in the manufacture of large-scale products, including railway components, ships, conveyors, bridge components, and lifting equipment.

Horizontal Machining Center Advantages

Next, here are some of the advantages of horizontal machining centers. What are its advantages over universal milling machines and vertical machining centers?

Productivity Improvement

With automatic tool change and numerical control, horizontal machining centers can further automate operations. Once programs are created, the machining center can automate cutting operations and tool changes, allowing it to shorten work times and execute continuous production.

Also, the machining center can position the spindle accurately to the micrometer level for improved quality.

Improved Operator Safety

Universal machine tools generally do not have a safety cover and machine with both the workpiece and tool exposed. Meanwhile, in a machining center, the spindle and table are covered with full covers. While this does not fully eliminate the risk of injury or accident, when used properly, a machining center can improve operator safety.

Works With Tall Workpieces and Multi-Face Machining

Many types of horizontal machining centers have vast space above the table, making them suitable for machining of taller workpieces. In addition, by rotating the table, all sides can be machined without having to load and unload the workpiece.

Improved Chip Evacuation

Due to the fact that the workpiece is machined horizontally, chips are more likely to fall off in horizontal machining centers. As the chips will evacuate naturally, this keeps the cutting area clear, resulting in less reduction in machining accuracy.

Horizontal Machining Center Disadvantages

While horizontal machining centers have many advantages, they also have some disadvantages. When considering a horizontal machining center, be sure to familiarize yourself with the following characteristics.

Large Footprint

Horizontal machining centers tend to take up a larger base surface area than vertical machining centers. If a machining center is installed in a factory space that is too small for it, the working area may feel cramped. When considering a new equipment introduction, it is important to consider the optimal machine size for the factory space while consulting.

In recent years, compact horizontal machining centers have been on the rise. For example, the Brother H550Xd1 can be installed in an area of 1,557 mm (61.3 inch) (width) x 2,990 mm (117.7 inch) (depth). It allows space-saving installation compared to regular horizontal machining centers.

More Complex Structure Than Vertical Machining Centers

Structurally, horizontal machining centers are more complex than vertical machining centers. Tasks such as programming and maintenance are generally more difficult than for vertical machining centers. On the other hand, given the wide range of operations that the horizontal machining center is capable of, used properly, it can result in more product insourcing or new project orders.

Shank Performance of Horizontal Machining Centers

Horizontal machining centers are also categorized by tool shank size into BT30, BT40, BT50, and so on.

| Nominal Number | Reference Dimension ΦD (Diameter at Thickest Point of Shank) |

|---|---|

| BT30 | 31.75 mm (1.25 inch) |

| BT40 | 44.45 mm (1.75 inch) |

| BT50 | 69.85 mm (2.74 inch) |

There are also BT55, BT60, and other sizes, but for horizontal machining centers, BT30-50 are the mainstream sizes. Here are the characteristics of each. Note here that the BT standard name stands for "bottle grip taper" and refers to the adapter that connects the spindle and tool.

BT30

A BT30 horizontal machining center is a machining center with a shank diameter of 31.75 mm (1.25 inch). These are suited for machining of small to medium-sized parts, and the size of the machine tool itself is also relatively compact. Generally speaking, small machining center refers to BT30, and these machining centers see use in the manufacture of a wide range of metal products, such as automobile parts and small electronic parts.

BT40

BT40 is a machining center with a shank diameter of 44.45 mm (1.75 inch). BT40 models are highly versatile, and many have higher cutting power than BT30 models. However, BT40 models come at a higher market price than for BT30, and they are also larger.

BT50

BT50 horizontal machining centers have excellent rigidity and are particularly good at machining large parts and heavy materials. There are BT50 models with table sizes over 500 mm (19.7 inch) and models that can machine heavier workpieces than BT30 and BT40 can.

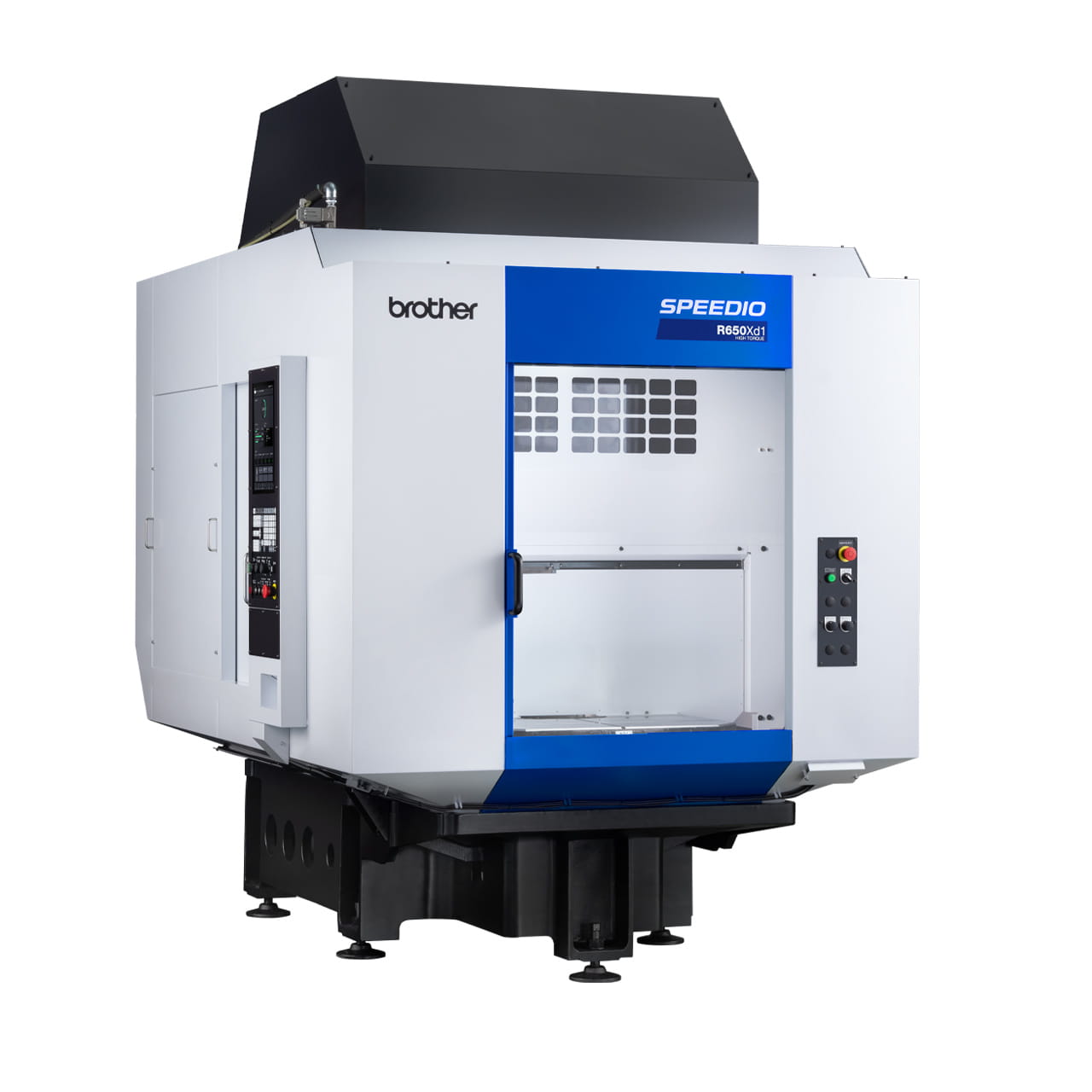

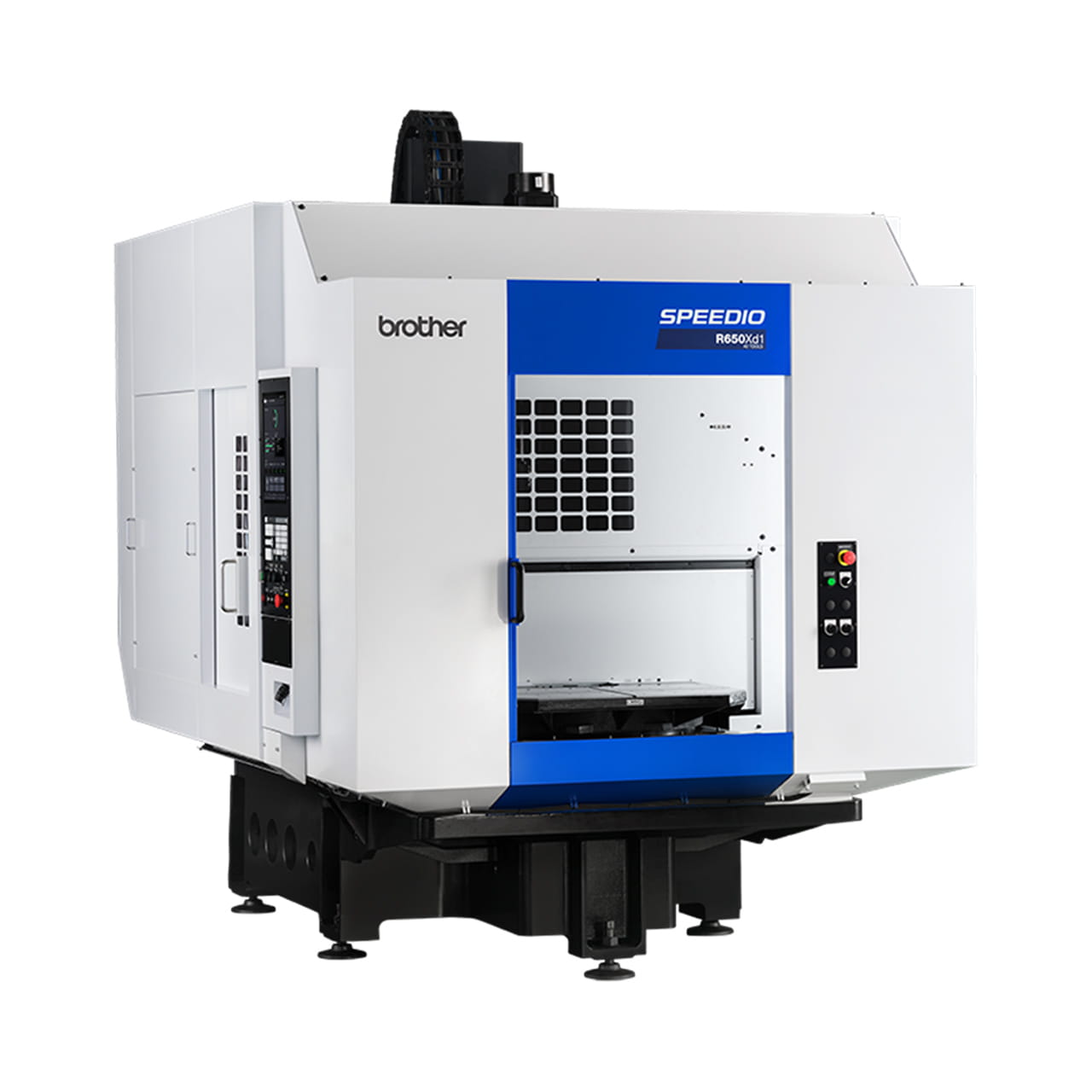

H550Xd1: Brother's High-Productivity Horizontal Machining Center

The Brother H550Xd1 is a BT30 horizontal machining center. Despite its compact body, its cutting capacity is higher than a BT40 model. The Brother SPEEDIO series, which includes the H550Xd1, also offers excellent environmental performance and greatly reduces power consumption over the average BT40 machining center.

Development Concept

In recent years, carbon neutrality is demanded even in the manufacturing industry. Building a sustainable production system, such as by reducing CO2 emissions in the manufacturing process and reducing power consumption, has grown to be an important management issue for manufacturers.

In addition, the accelerating trend towards EVs in the automotive industry has changed the needs of machine tools dramatically. In particular, with the added complexity of EV parts over gas-powered car parts, there is a growing demand for horizontal machining centers for their ability to consolidate multiple processes into a single machine.

The H550Xd1 was developed against this backdrop. With its ability to handle multi-face machining of medium to large workpieces despite its compact body, the H550Xd1 is being introduced by companies working on productivity improvement and automation.

Versatile Body Performance

The H550Xd1 comes standard with a B-axis table that uses a roller gear cam mechanism. The table size is 400 mm (15.7 inch) x 400 mm (15.7 inch), with a high-speed rotary speed of 100 min-1. It can handle heavy workpieces (can machine up to 300kg (661 lbs)) and has a wide jig area of Φ600 mm (23.6 inch) × 580 mm (22.8 inch).

The size of the machine body is 1557 mm (61.3 inch) wide and 2990 mm (117.7 inch) deep. This can reduce installation space by approximately 20% over the typical BT40 horizontal machining center. The automatic tool changer (ATC) comes with a 30-tool magazine that accepts tools up to a maximum length of 250 mm (9.8 inch) and a maximum diameter of 125 mm (4.9 inch).

Pursuit of High Productivity

For high performance, the H550Xd1 is equipped with features including a high-speed spindle, tool change optimization, and inertia estimation. Spindle start/stop time is kept to within 0.15 seconds, and cutting tool changes complete in 1.1 seconds. The inertia estimation feature can automatically determine the inertia according to the jig attached to the B-axis table.

CNC

As the H550Xd1 is built for daily use, much attention has also been paid to making it easy to use and operate. The home screen display lists programs, tool life, and more, providing one-touch access to the information you need. In addition, our support apps allow you to check machining results and visualize power consumption, helping you to formulate measures to improve productivity, such as by shortening cycle times and reducing power consumption.

Safe Production

In terms of safe production, the H550Xd1 features high chip evacuation, ATC monitoring, and machining load monitoring. It is built to prevent machining errors and is equipped with an early detection feature in the unlikely event a defect occurs. Line stoppages of machine tools directly impact the profitability of production. The H550Xd1 has been designed to minimize the risk of downtime.

Product Page

First, See It for Yourself

Brother Industries has showrooms in Tokyo, Osaka, Aichi, and other Japanese cities. Come see and feel the latest machines, or consult with us about any manufacturing-related issues or concerns. If looking to automate your cutting and considering introducing new machine tools, please feel free to schedule a consultation.

Author: Yuki Kobayashi

Editor: EGGO CO., LTD.

Related Articles

Learn the Rules for Metal Material Codes! The Meaning and Reading of JIS Codes Explained