- Products

- Support & Download

- Solutions

- Contacts

- About Brother

SPEEDIO

S300Xd1 / S500Xd1 / S700Xd1 Features

Equipped with new "CNC-D00" controller to improve productivity and usability.

Using a new 28-tool magazine increases target workpieces, leading to process integration.

Process Integration

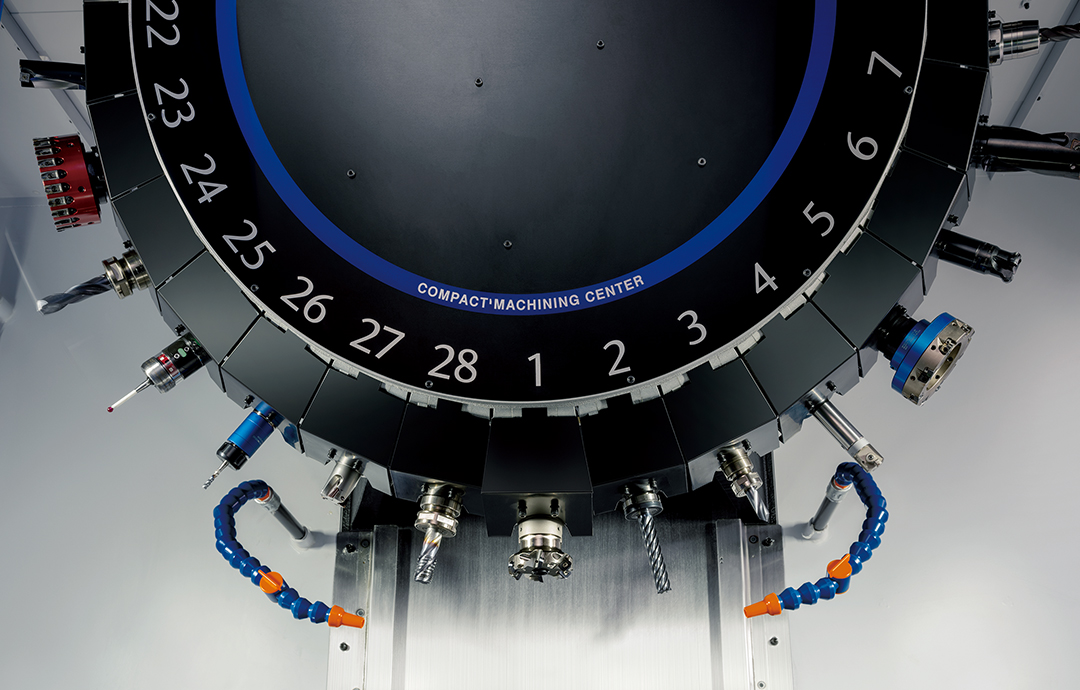

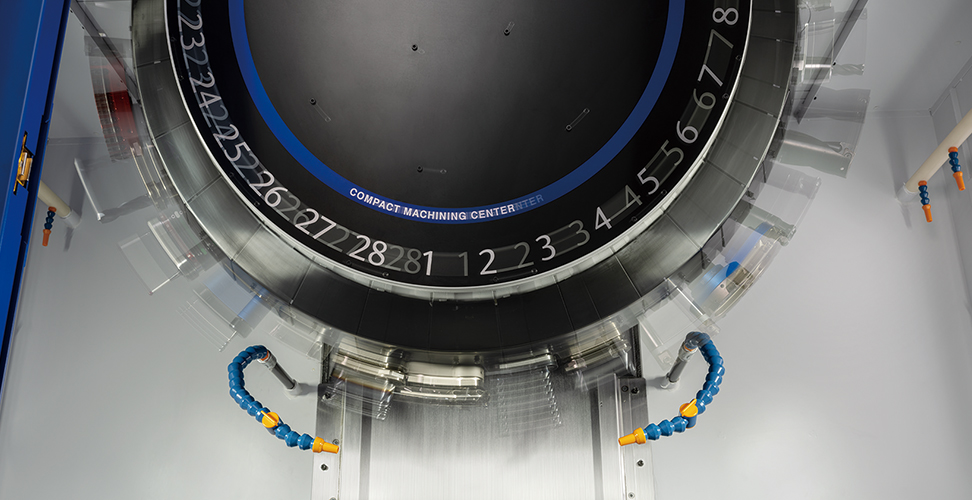

New 28-tool magazine makes wider variety of machining

possible on one machine, promoting process integration

Together with the extensive range of specifications, the machine is suitable for a broad range of machining.

28-tool magazine

In addition to 14- and 21-tool magazines, a compact drum type 28-tool magazine has been developed with high-speed tool change performance maintained. The maximum tool weight has been improved to 4 kg*.

* The 28-tool magazine cannot be selected for the S300Xd1.

Max. table loading capacity 400 kg

The maximum table loading capacity has been increased to 400 kg*. This expands choices of fixtures and promotes process integration.

* Parameter setting must be changed for table loading capacity 400kg. Max. table loading capacity is 300kg for the S300Xd1.

Productivity

Untiring pursuit of high productivity

Reduction in waste by optimizing control through machine/controller integrated development

Drives highly reliable machine performance to the limit to provide high productivity.

Non-stop ATC

High-speed tool change has been achieved by faster and optimized spindle start/stop, Z-axis up/down, and magazine operation. Tools up to 3 kg can be changed in the shortest time. Tools up to 4 kg can also be changed with minimal increase in time.

Simultaneous operation

High acceleration/deceleration spindle

Machining Capability

Highly rigid machine structure and highly efficient spindle motor enable a broad range of machining

Prepared spindles applicable to machining in various industries, from automobile to semiconductor, precision parts, and IT equipment industries.The new NC with improved processing speed achieves high speed and high accuracy performance even in three-dimensional machining.

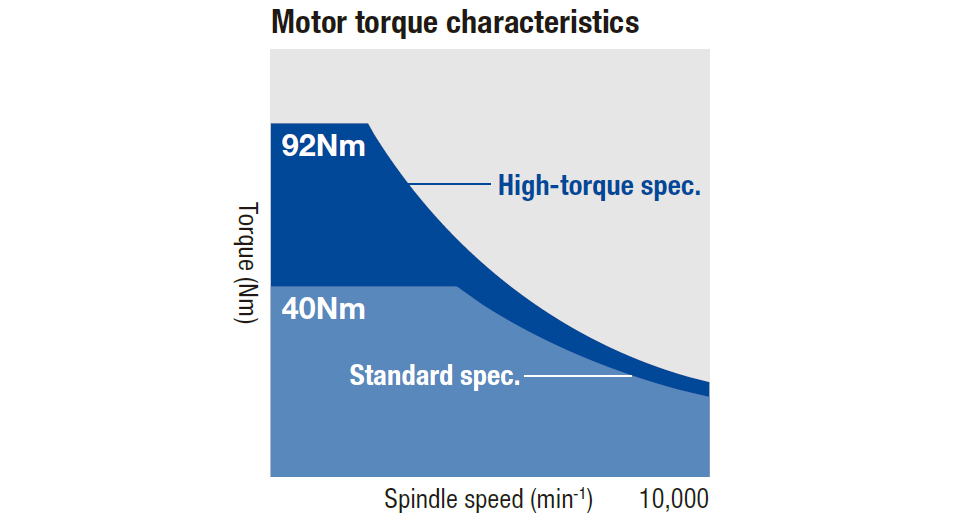

Heavy-duty/highly-efficient machining using highly efficient spindle motor

A spindle motor with high torque in the medium- and high-speed range is used to achieve high-speed and highly efficient machining. In addition, the high-torque spec.

(optional) machine demonstrates higher torque in the medium- and high-speed range, and greatly improves torque in the low-speed range. The machine provides excellent performance in heavy-duty machining such as large-diameter drilling and tapping.

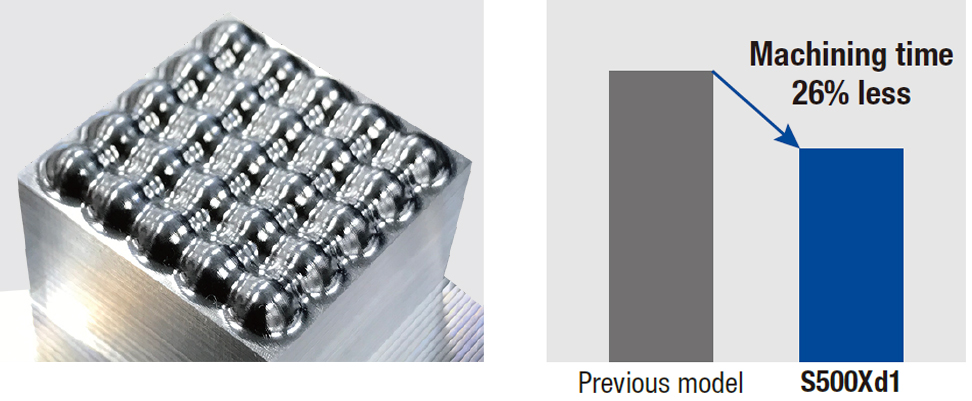

High-speed and highly accurate three-dimensional machining using high-speed spindle and high accuracy mode

In addition to the highly-responsive servo control, the servo processing speed and resolution have been greatly improved. Enhanced original three-dimensional machining control, including increased look-ahead blocks and improved surface quality by the smooth path offset function, achieves high-speed and highly accurate three-dimensional machining.

Processing speed improved fourfold

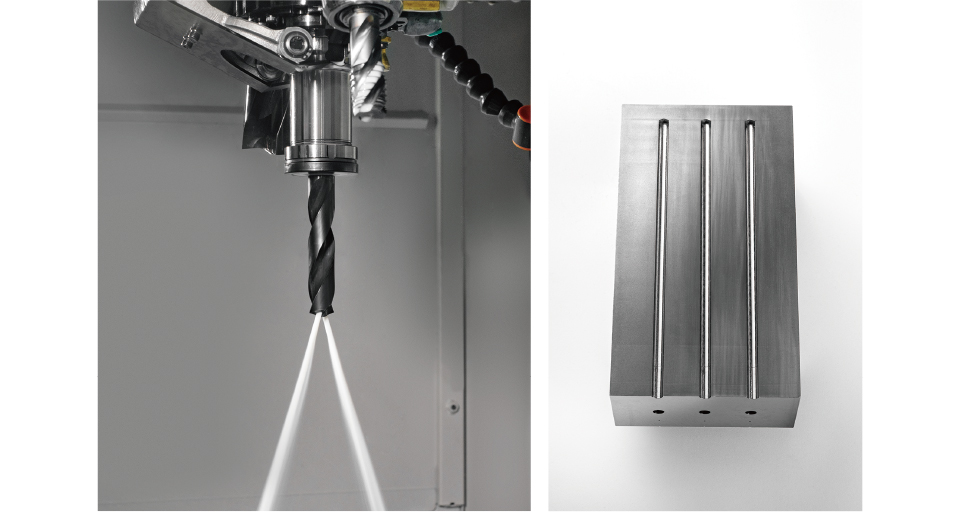

7 MPa Coolant Through Spindle (CTS) (optional)

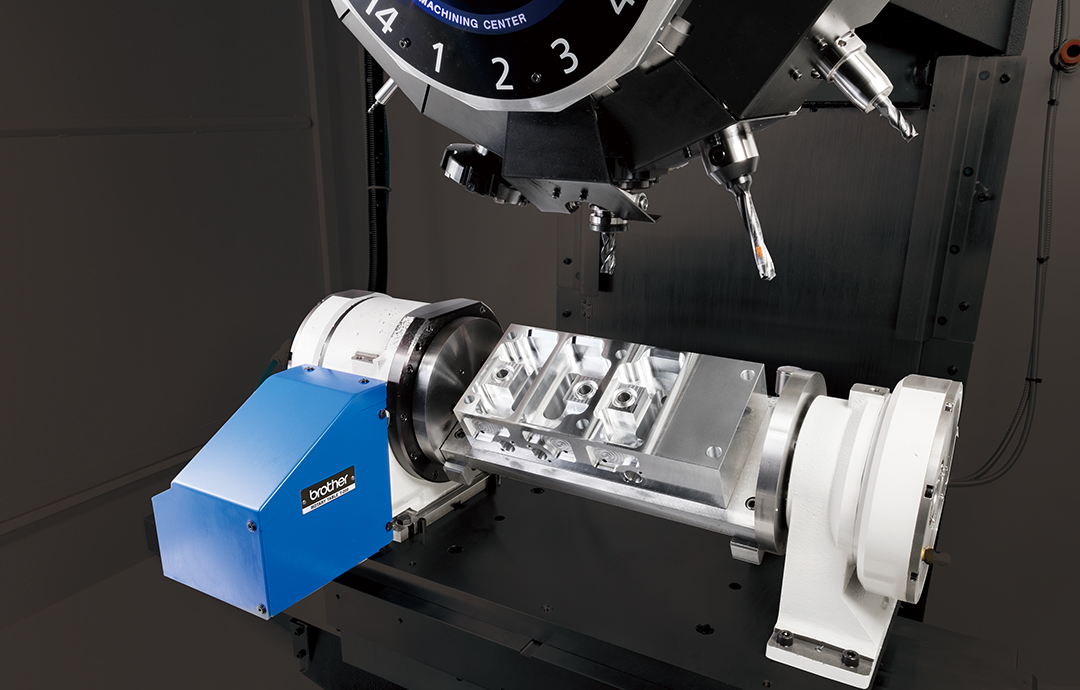

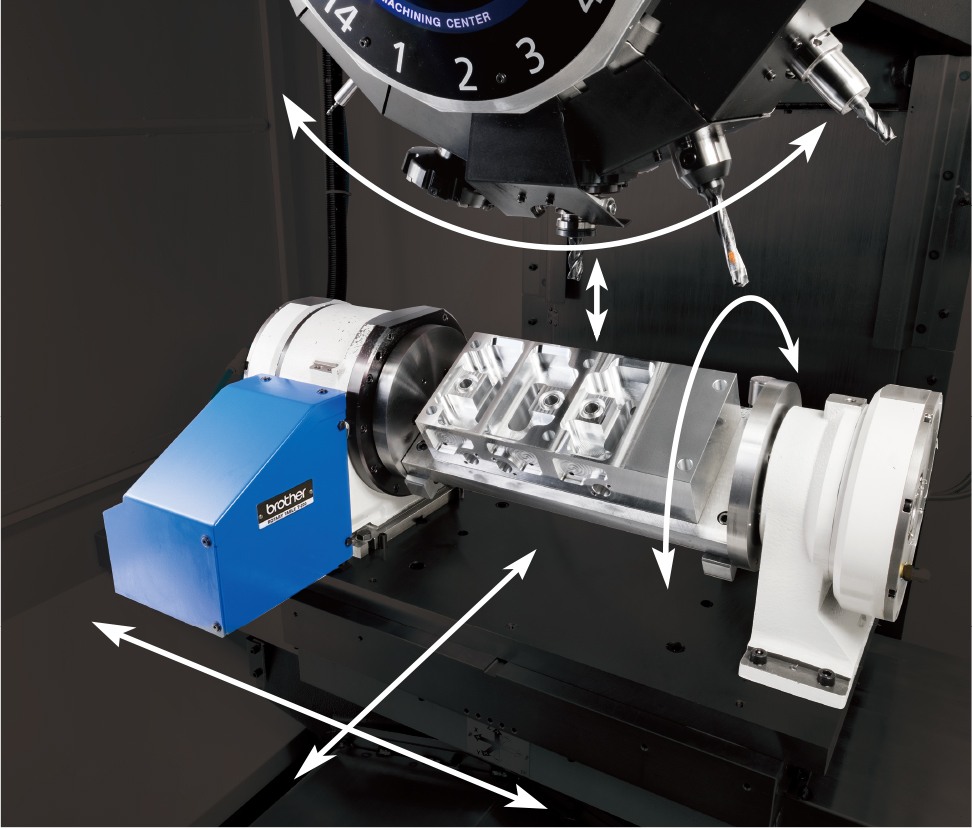

Simultaneous 5-axis machining

Provided with functions required for simultaneous 5-axis machining, including tool center point control where machining is performed by changing the tool direction relative to the workpiece, look-ahead max. 1,000 blocks, and submicron command. For the new CNC-D00 controller, the CPU capacity has been greatly increased to enhance processing of minute line segments by fourfold the conventional controller. This enables high-speed processing of CAM data with small tolerance.

- NC functions related to simultaneous 5-axis machining *

-

Tool center point control (look-ahead 1,000 blocks),

submicron command,

Feature coordinates setting,

memory capacity (3 Gbytes)* All these are standard on the S300Xd1-5AX / S500Xd1-5AX / S700Xd1-5AX.

NC Controller

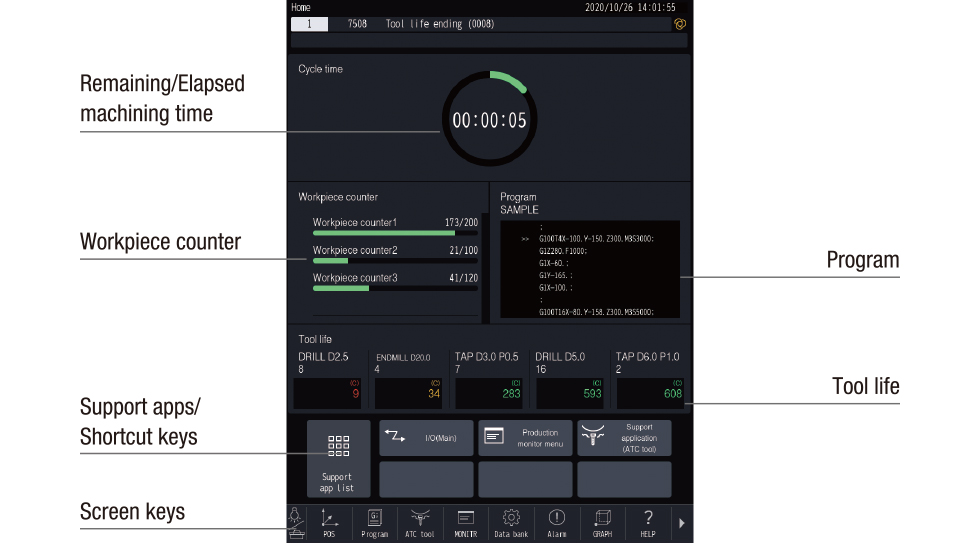

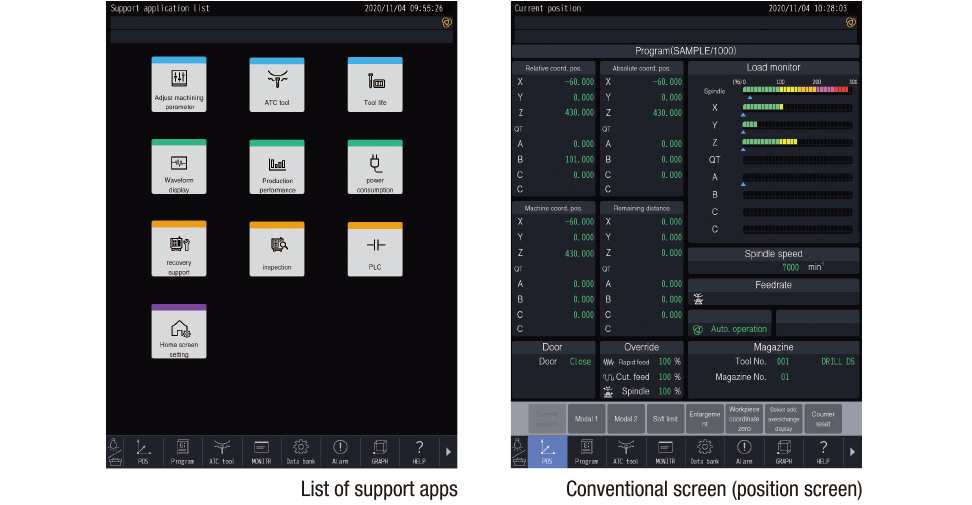

Equipped with new “CNC-D00” controller

Enhanced usability with 15-inch LCD touch panel

Home screen

New user interface

Customer considering purchase / Support Information

-

Catalog download

Guide of Compact machining center SPEEDIO catalog download.

-

Distributors - Inquiry & Purchase , Repair & Service

Contact information for distributors in your area.

-

Brother Technology Center

Contact information for Brother Technical Centers in Europe and other areas.