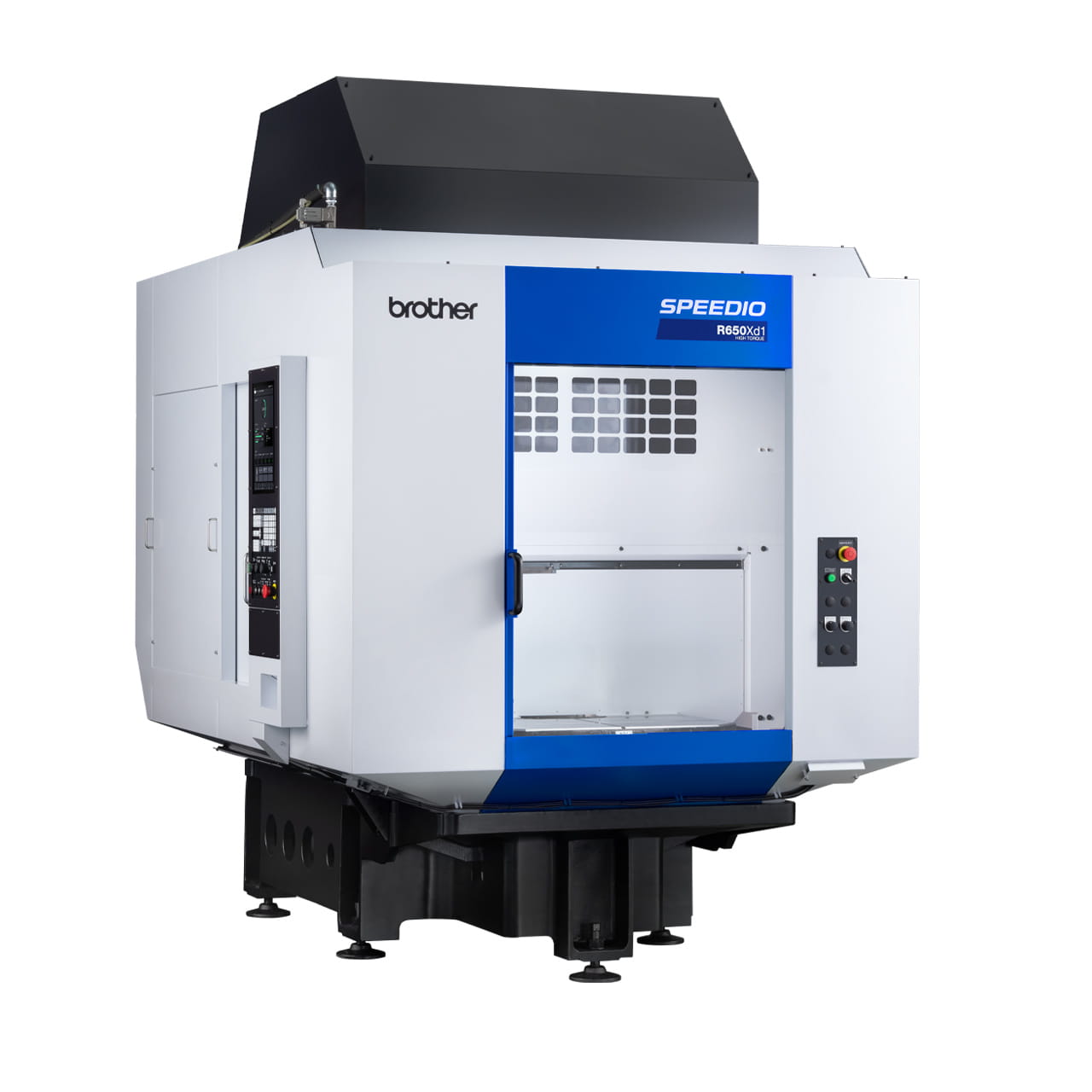

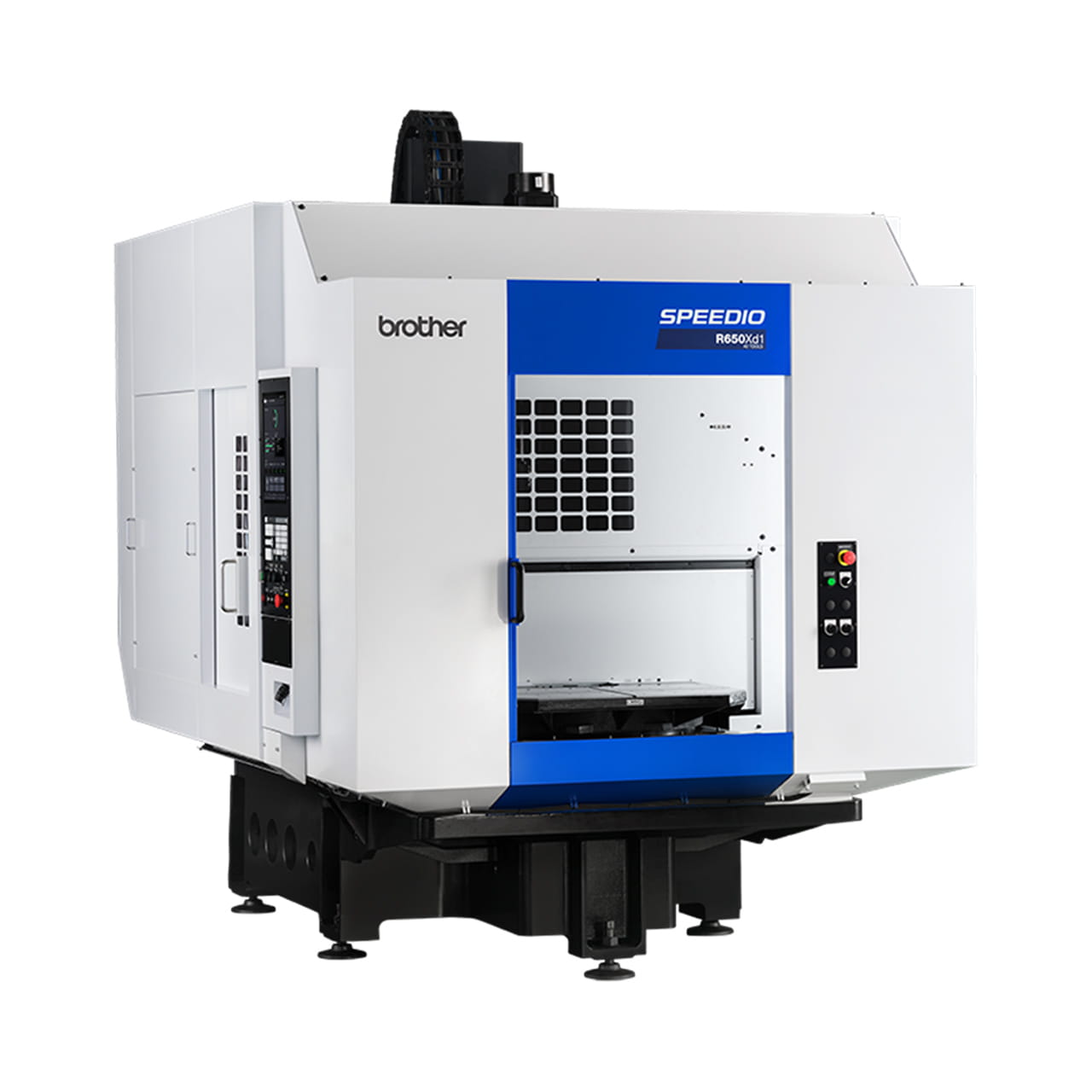

SPEEDIO U500Xd2-100T

Universal Compact Machining Center

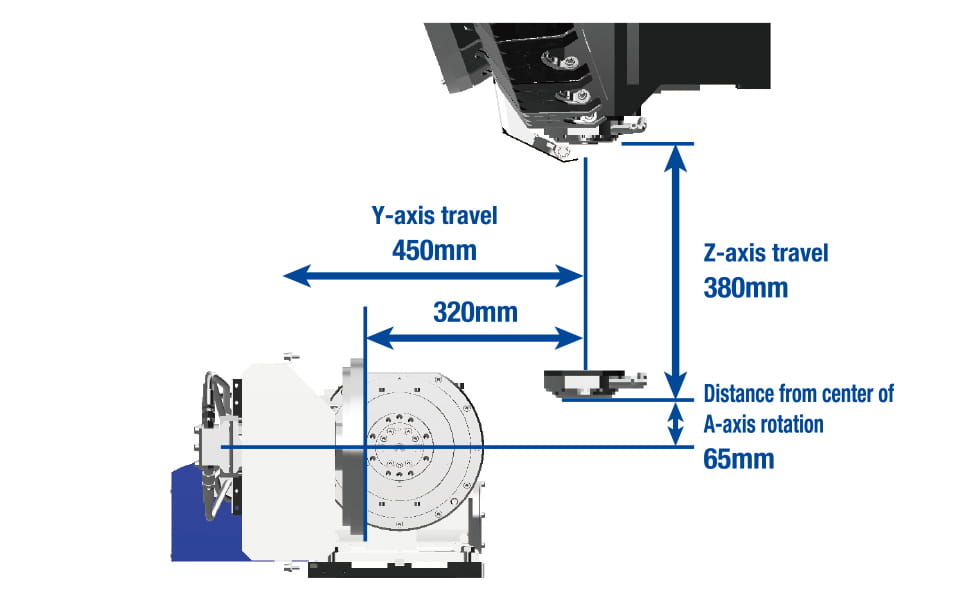

- Travels (mm): X: 500 Y: 450 Z: 380

- Max. spindle speed (min-1): 12,000/ (Optional) 10,000 high-torque/ (Optional) 20,000

- Tool storage capacity(pcs.): 100

Select variant: U500Xd2-5AX 100T

[BT30 Vertical compact machining center]

100-tool magazine model

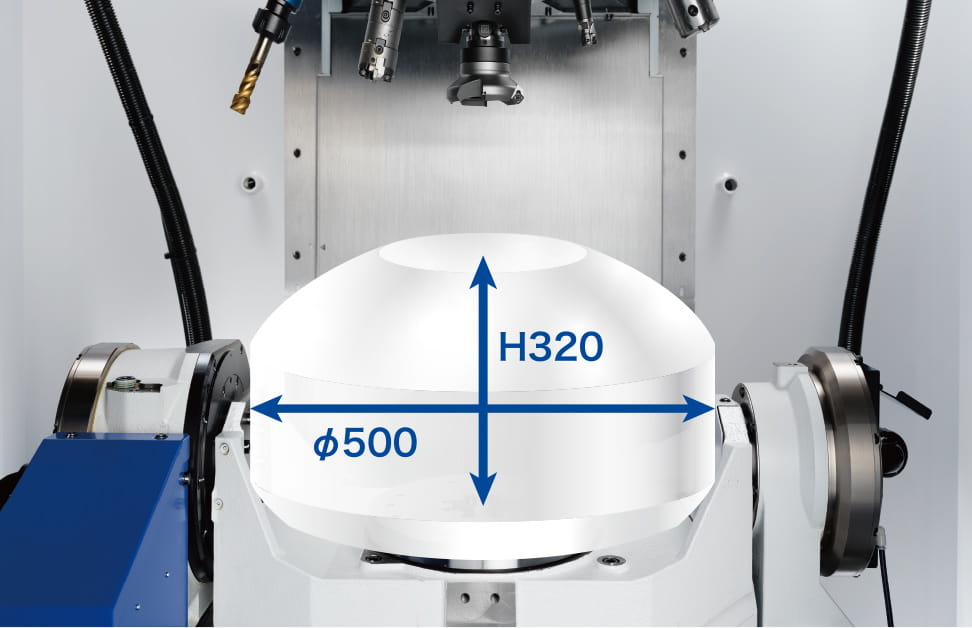

with a tilting rotary table with a jig area of ø500 mm

Improves efficiency of high-mix small-lot production

Information

Overview

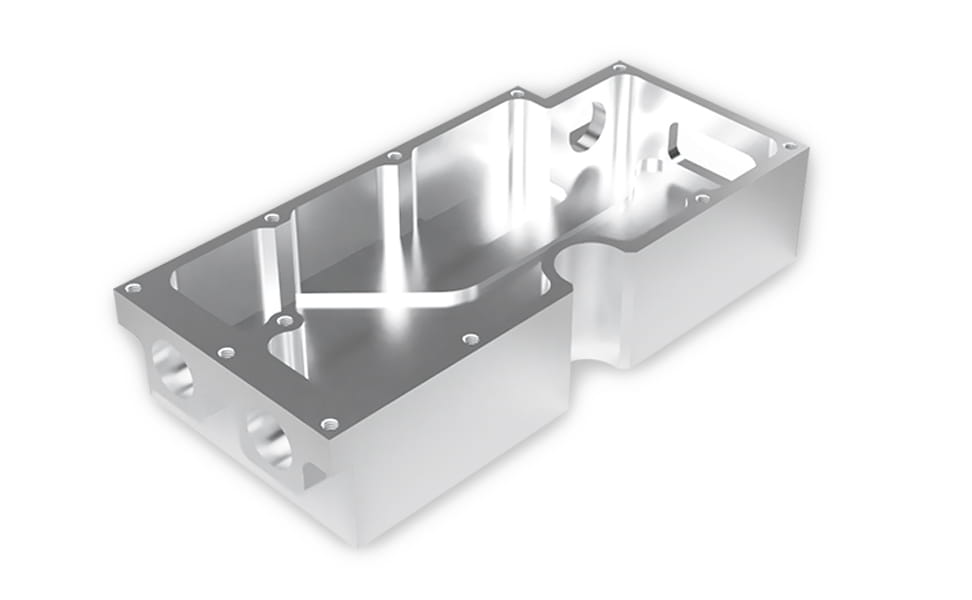

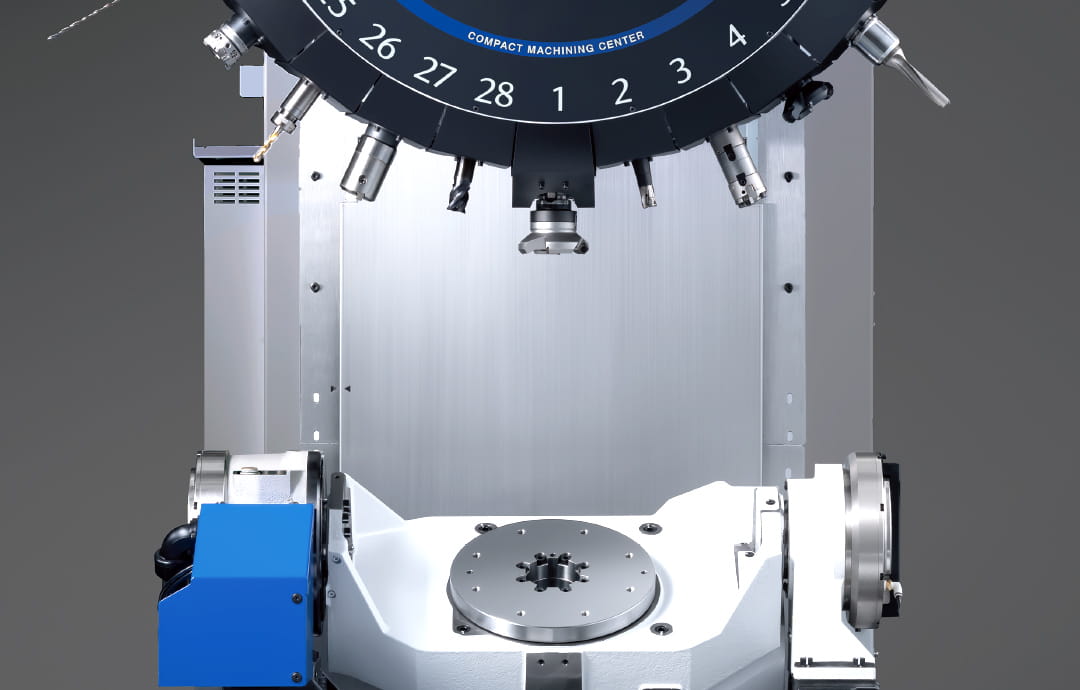

Standard equipped with a high-speed, highly accurate tilting rotary table with ample jig area.

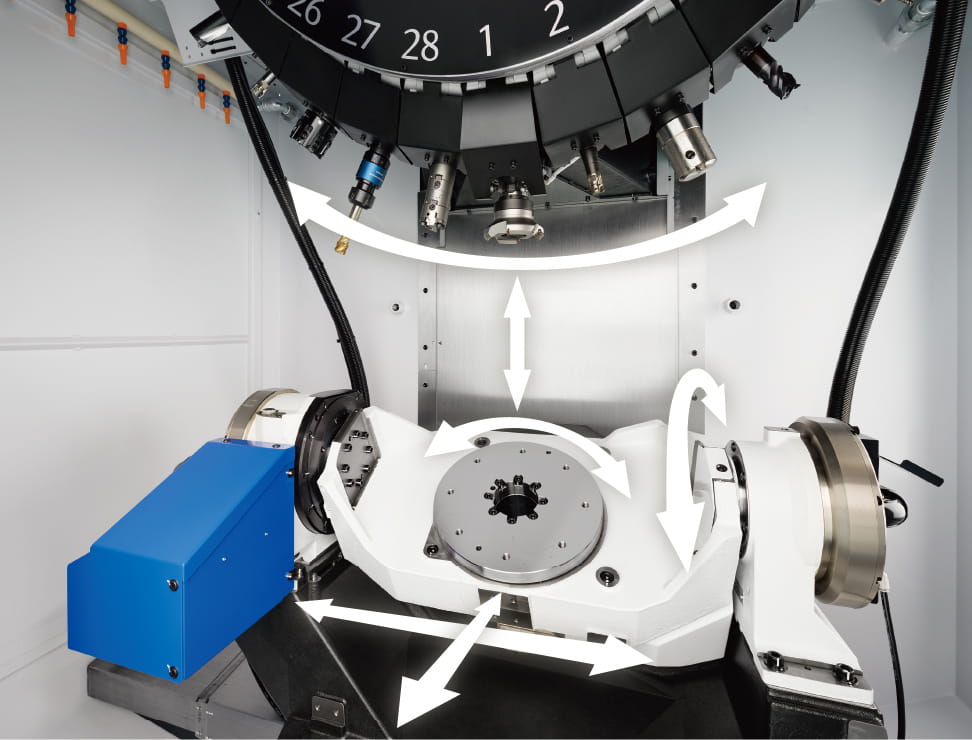

Increased travels of Y/Z axes and using a magazine that can store up to 28 tools further accelerates process integration by one-clamp machining.

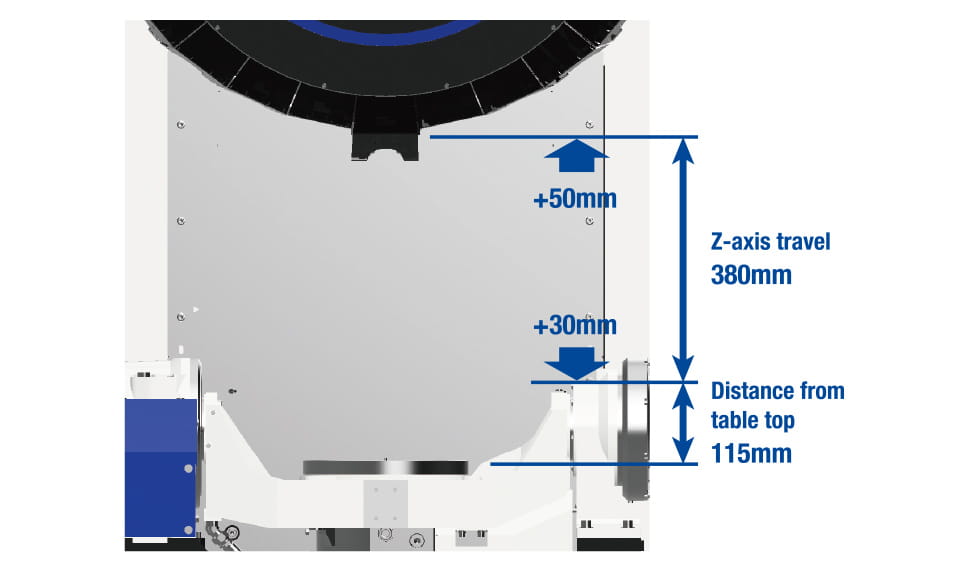

Z-axis travel

300mm (Previous model) → 380mm

Y-axis travel

400mm (Previous model) → 450mm

Max. loading weight 100kg

* Refer to the External Dimensions on page 17 for details of the jig area.

28-tool magazine

Max. tool diameter 110mm

Max. tool weight 4kg

Max. total tool weight 35kg

Tool-Tool 0.7s

Pursuing fast acceleration and quick response through machine/controller integrated development and optimizing control with the “CNC-D00” controller drive machine performance to the limit to provide high productivity.

Non-stop ATC

High-speed tool change has been achieved by faster and optimized spindle start/stop, Z-axis up/down, and magazine operation. Tools up to 3 kg can be changed in the shortest time. Tools up to 4 kg can also be changed with minimal increase in time.

14/21 tools (Standard tools) Tool-Tool 0.6s / Chip-Chip 1.3s

28 tools (Standard tools) Tool-Tool 0.7s / Chip-Chip 1.4s

28 tools (Heavy tools) Tool-Tool 0.8s / Chip-Chip 1.4s

Simultaneous operation

Wasted time has been reduced by simultaneously performing tool change and positioning X/Y and additional axes.

Magazine load conditions estimate *

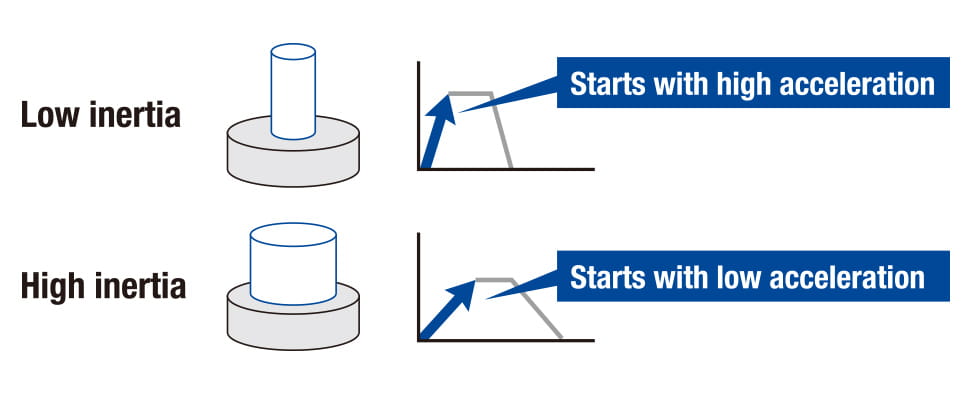

Estimates the inertia and unbalanced load of the tool loaded in the magazine, and sets the optimum value for the acceleration of the magazine axis. In addition, automatically updates the value to the estimated optimum acceleration, even during programmed operation.

* Cannot be used for tool stockers of the U500Xd2-100T.

Optimized A/C-axes indexing feed rate

Based on the estimated A/C-axes inertia, the A/C-axes start with optimal acceleration until they reach the indexing feed rate.

Improved automatic door opening/closing speed

The automatic door opening/closing speed has been improved, enabling significant reduction in setup time.

Automatic door opening/closing time 20% less

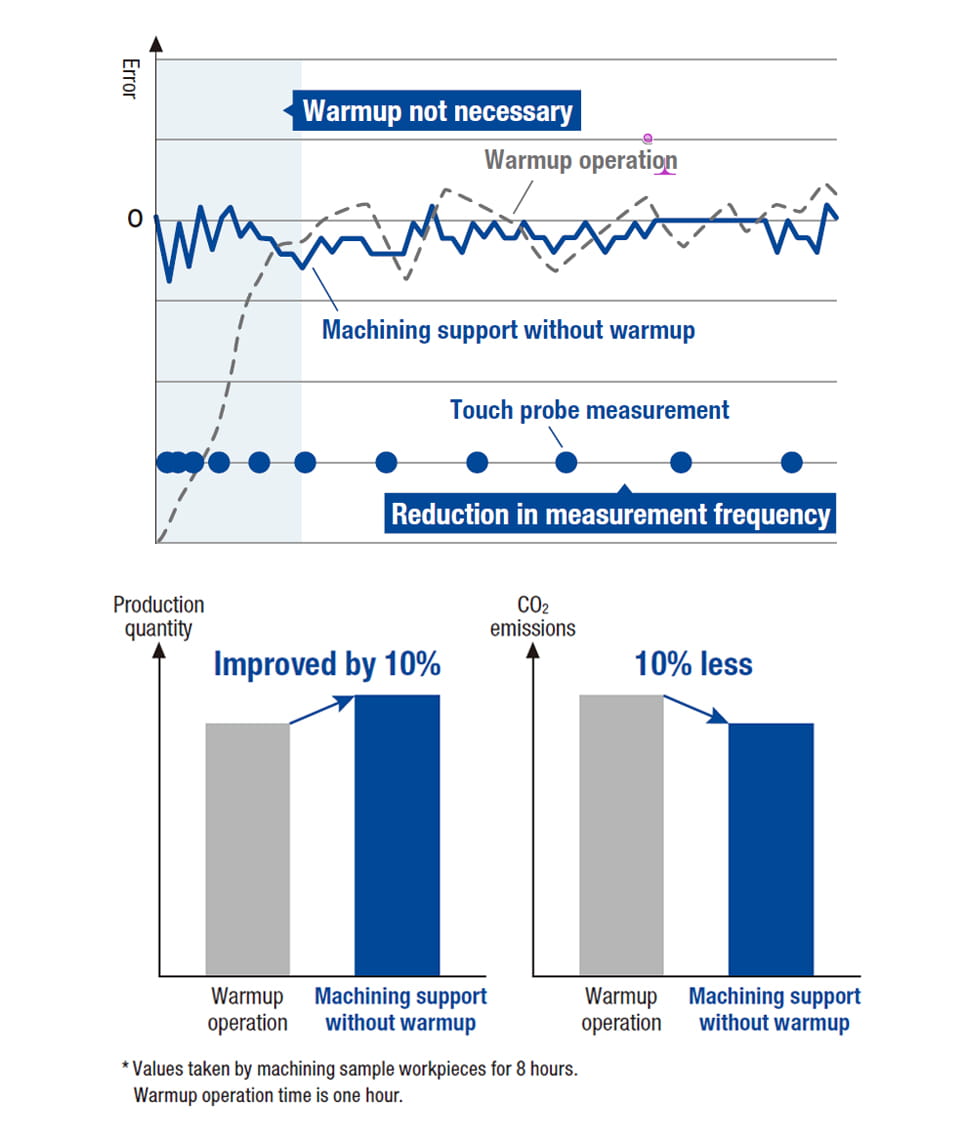

Machining support without warmup

Equipped with an original measurement processing function that reduces the number of actual measurements by a touch probe according to the size of displacement.

This eliminates the need for warmup operation, minimizing effects on productivity to achieve highly accurate machining.

Reliable and trustworthy machine structure has been achieved.

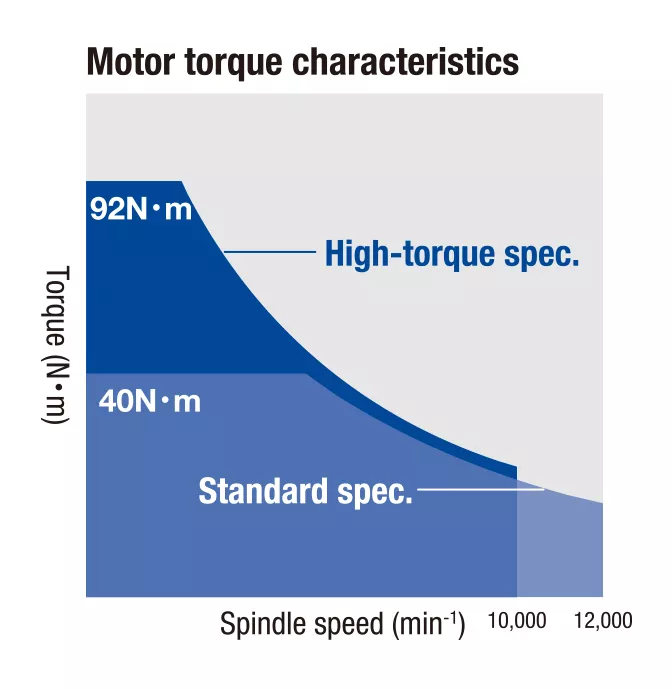

Equipped with a highly efficient spindle motor that demonstrates sufficient torque from the low- to high-speed range.

Achieves highly efficient machining in various industries, from automobile to general machinery, medical, and aircraft industries.

Tool center point control has been added to support simultaneous five-axis machining.*

*Available only for the U500Xd2-5AX.

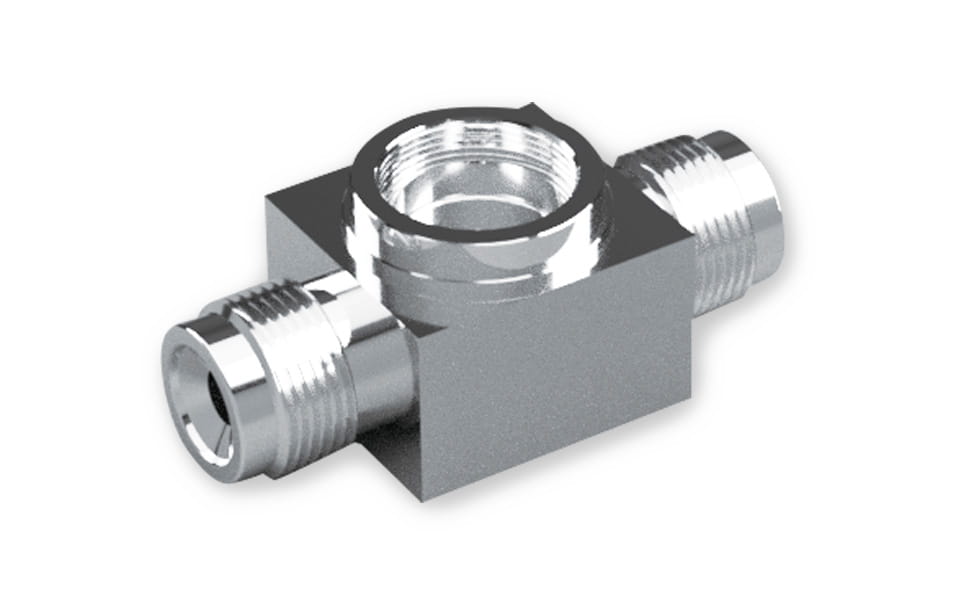

Newly developed and highly efficient 20,000 min-1 spindle motor

A new 20,000 min-1 spindle motor has been developed. Compatible with the Coolant Through Spindle (CTS), this motor further improves productivity of small-diameter drilling. A variety of spindle specifications are available, including the standard 12,000 min-1 spec. and high-torque spec.

High-torque spec. (optional)

Max. torque 92N・m

Max. output 26.2kW

20,000 min-1 spec. (optional)

Max. torque 27N・m

Max. output 15.4kW

12,000 min-1 spec. (standard)

Max. torque 40N・m

Max. output 18.9kW

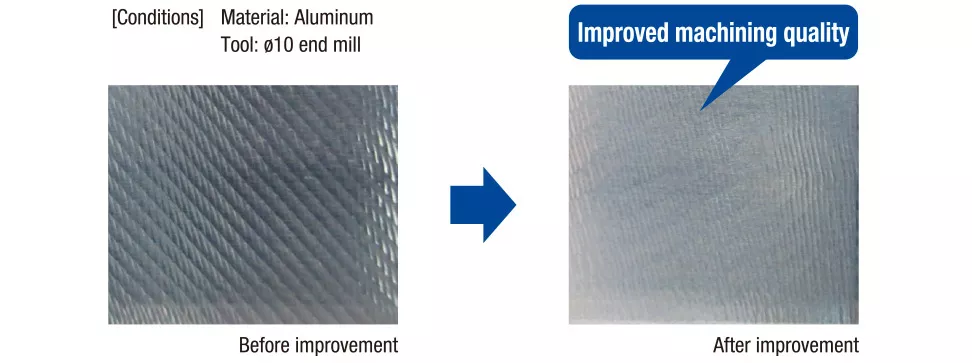

Vibration adjustment analyzes waveform data using a PC app to suggest the recommended spindle speed. Optimal machining conditions drive machining performance to the fullest.

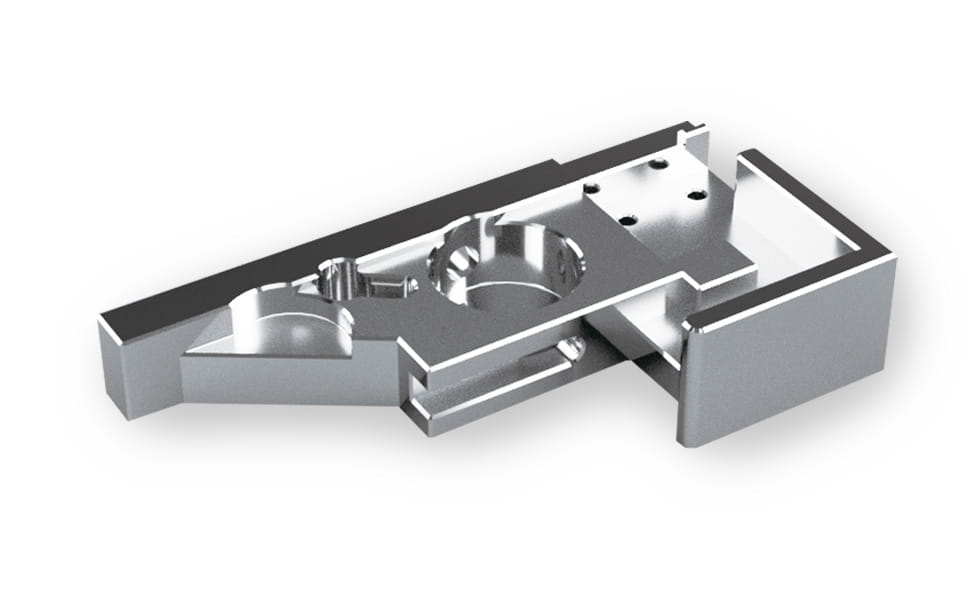

Simultaneous 5-axis machining

Equipped with a variety of functions, including tool center point control and submicron command, to achieve high-speed and highly accurate simultaneous 5-axis machining.

* Changing to the conversation language is not possible for the simultaneous 5-axis specifications (5AX).

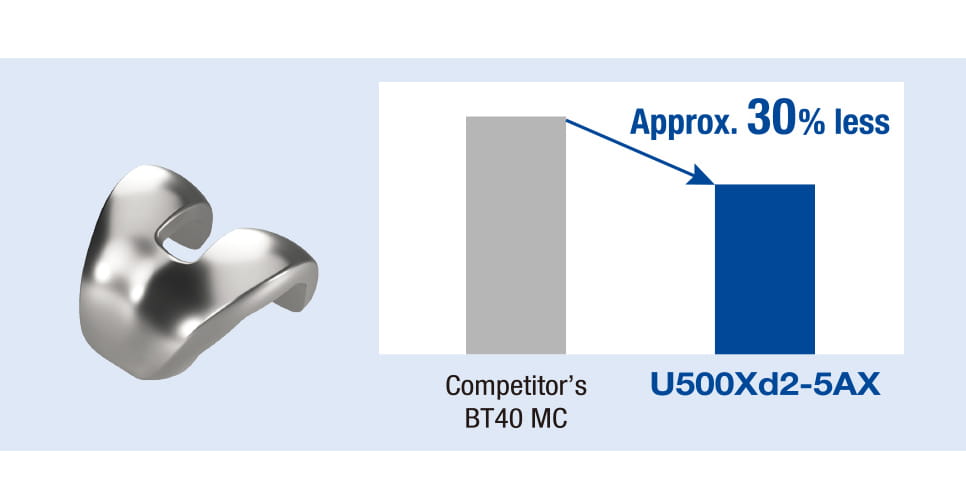

Productivity improvement

In addition to the compactness of the BT30, the original look-ahead acceleration/deceleration processing maximizes the machine's performance

(max. speed and acceleration) to achieve high-speed simultaneous 5-axis machining.

Comparison with cycle time by

competitor’s BT40 MC

Workpiece: Knee joint

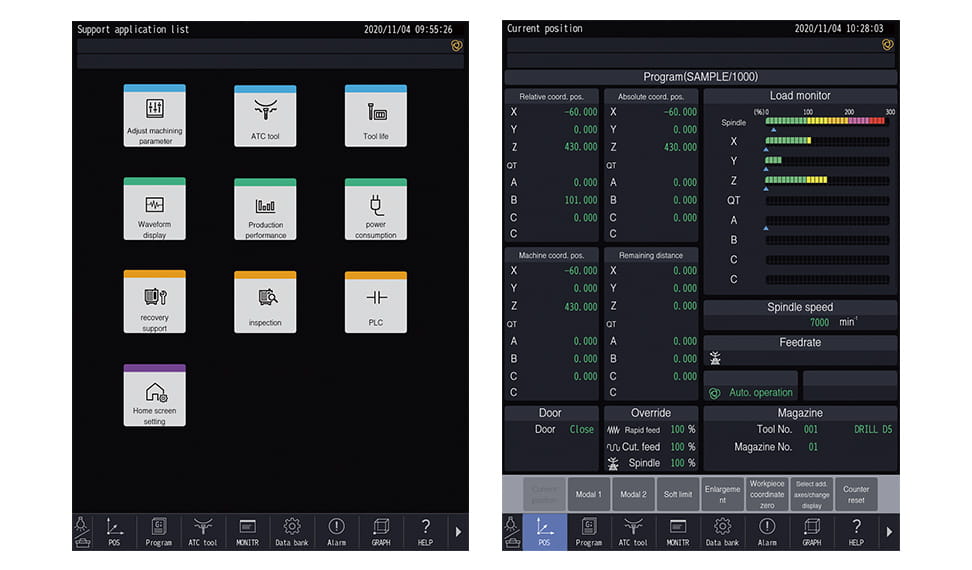

Intuitive operation is possible with apps and vertical touch panel screen. Relevant functions are grouped according to purpose, such as setup and machining, leading to efficient operation. Production and operation states are visualized, allowing faster understanding. Waste-free operation is possible in setup, machining adjustment, production, and recovery process, leading to improved work efficiency and operating rate.

User interface

Equipped with support apps with improved operability and visibility by grouping relevant functions and an easy-to-view display, in addition to several useful accessories (calculator, notebook, file viewer etc.). Operation on conventional screens is possible on the touch panel.

With these, usability has been greatly improved.

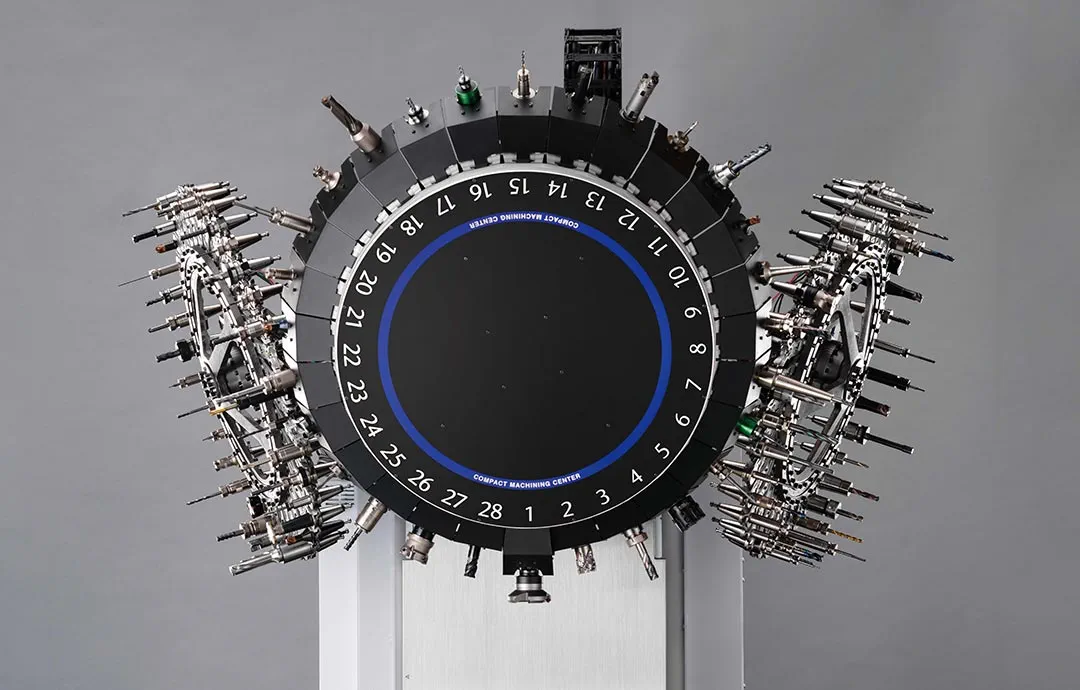

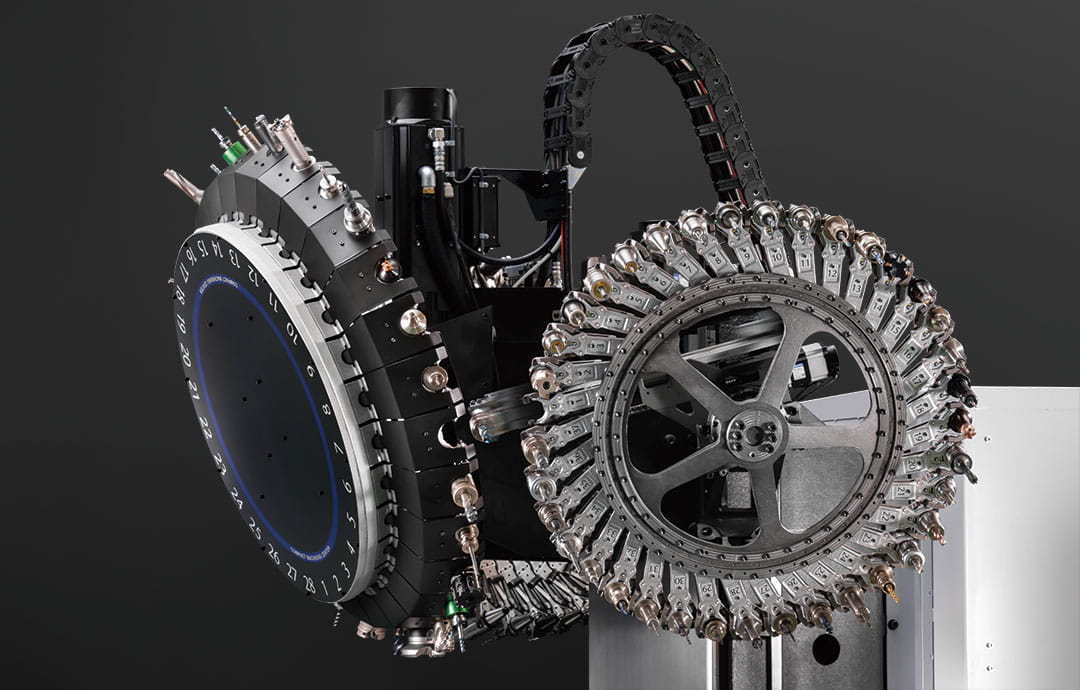

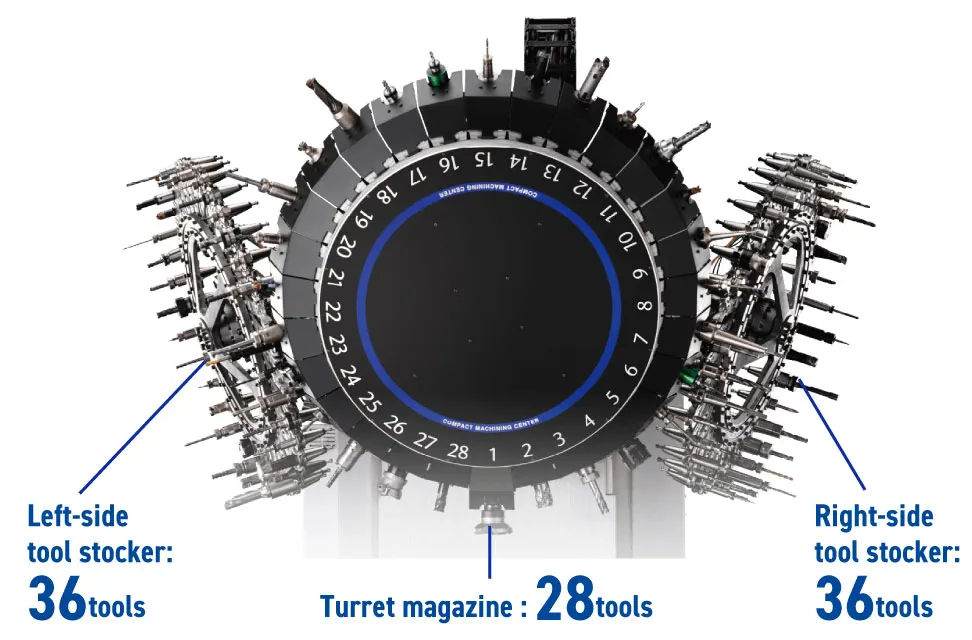

The new 100-tool magazine, featuring the largest storage capacity in the SPEEDIO series, has been developed. *

Brother’s original mechanism achieves space saving and high productivity.

* Mounted only on the U500Xd2-100T. Conversation language not available on the U500Xd2-100T.

Newly developed 100-tool magazine (optional)

A tool stocker that can store 36 tools is installed on the right and left sides of the 28-tool turret magazine, enabling storage of 100 tools, the largest capacity in the SPEEDIO series.

Brother’s original tool handling mechanism achieves stable tool change.

100-tool magazine spec.

Turret magazine : 28 tools

Tool stocker (left/right) : 36 tools each

Total storage capacity : 100 tools

The stocker shutter separates the tool stocker from the machining chamber, minimizing the effect of chips on tools.

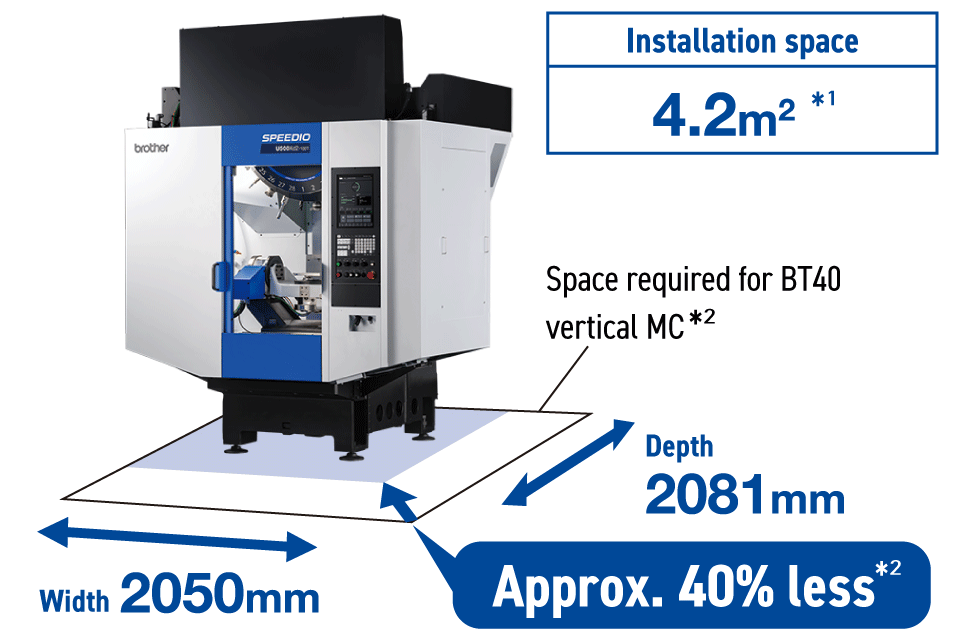

Space-saving design

Tool stockers are installed inside the machine to save space while storing 100 tools.

*1. Does not include coolant tank and chip conveyor

*2. Compared to BT40 vertical MC with equivalent tool storage capacity

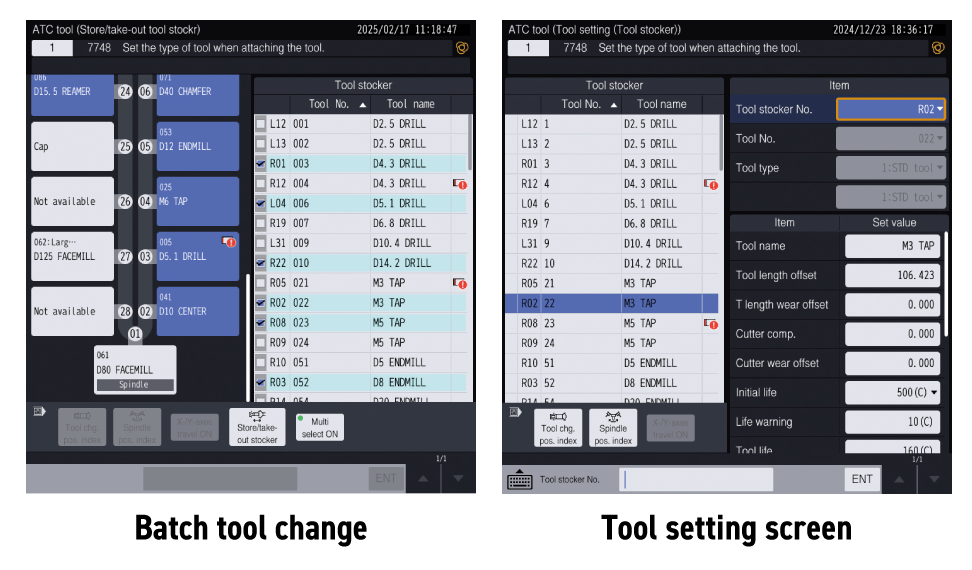

If the number of tools used in machining is 28 or less, high speed tool change is possible using only the turret magazine, leading to high productivity.

Even when using tools in the tool stocker, handling is possible within approximately 5 seconds (1 tool).

In addition, all tools in the turret magazine can be easily changed, reducing setup time.

Turret magazine tool change time

Tool to Tool : 0.7s

Chip to Chip : 1.4s

Tool stocker handling time *3

Shortest (1 tool) : Approx. 5s *4

All tool change (28 tools) : Approx. 140s

*3. Handling time varies depending on the tool attachment position.

*4. Time for the tool at spindle position to be moved and changed with a tool in the tool stocker and for this tool to return to spindle position.

A function for managing the 100-tool magazine has been added to the ATC tool app.

Tool change operation is intuitive, and tools to be used in the machining program can be moved from the tool stocker to the turret magazine in a batch.

In addition, data of tools in the tool stocker can be easily changed.

For high-mix small-lot workpieces, the 100-tool magazine eliminates the need for frequent tool changes, and the tilting rotary table with a jig area of ø500 mm enables multi-face machining and simultaneous 5-axis machining for a variety of workpieces with one-clamp.

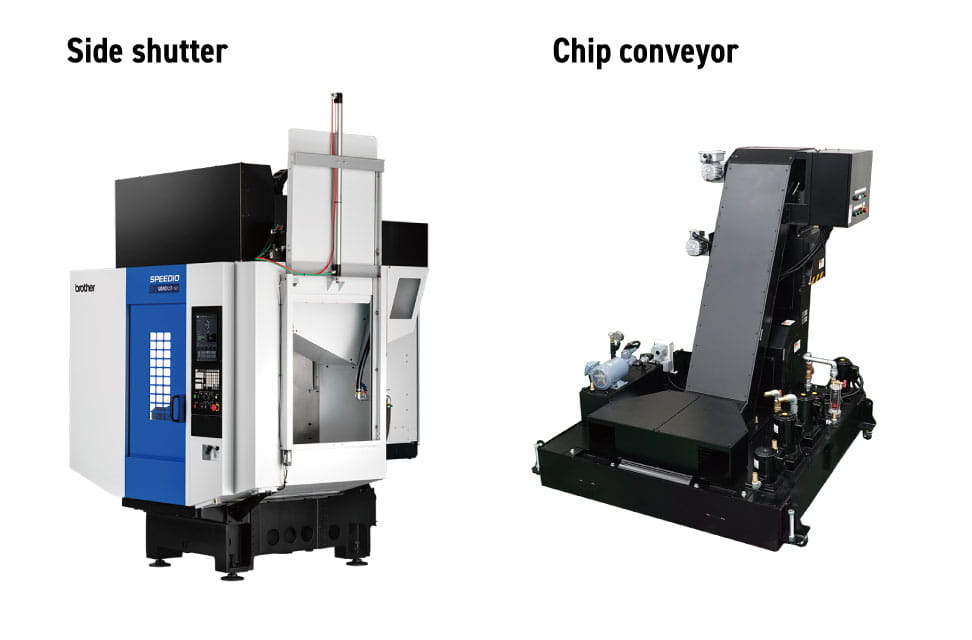

Assuming loading/unloading of workpieces from the side by robots, a side shutter has been prepared to make automation easier.

* A safety fence is required. Cannot be selected for the S300Xd2.

Two types of chip conveyors are available: scraper type and hinge + scraper type.

* Chip conveyors can only be selected for the U500Xd2-100T.

Specifications

Product Specification

U500Xd2-100T

Max. spindle speed [min⁻¹]

12,000/ (Optional) 10,000 high-torque/ (Optional) 20,000

Travels [mm (inch)]

X: 500 (19.7) Y: 450 (17.7) Z: 380 (15.0) A(deg.): -30 to 120 C(deg.):360

Tool storage capacity [pcs.]

100

Rapid traverse rate (XYZ axes) [m/min (inch/min)]

50 x 50 x 56 (1,969 x 1,969 x 2,205)

Indexing feed rate [min⁻¹]

A axis: 50, C axis: 75 (60 *9)

Required floor space [mm (inch)]

2,050 x 2,081 (80.7 × 81.9)

BT dual contact spindle(BIG-PLUS)

Optional

Coolant Through Spindle(CTS)

Optional

| Item | U500Xd2 U500Xd2 RD *8 U500Xd2-5AX U500Xd2-5AX RD *8 |

U500Xd2-100T U500Xd2-100T RD *8 U500Xd2-5AX/100T U500Xd2-5AX/100T RD *8 |

||

|---|---|---|---|---|

| CNC Unit | [U500Xd2] CNC-D00, [U500Xd2-5AX] CNC-D00v(DB) | |||

| Travels | X axis [mm (inch)] | 500 (19.7) | ||

| Y axis [mm (inch)] | 450 (17.7) | |||

| Z axis [mm (inch)] | 380 (15.0) | |||

| A axis [deg.] | -30 to 120 | |||

| C axis [deg.] | 360 | |||

| Distance between table top and spindle nose end [mm (inch)] | 115 - 495 (4.5 - 19.5) | |||

| Table | Work area size [mm (inch)] | ø260 (ø10.2) | ||

| Max.loading capacity (uniform load) [kg (lbs)] |

100 (220) | |||

| Max. table load inertia [kg・m2(lb・inch2)] |

1.8 (6,151) [2.6 (8,885) *9] | |||

| Spindle | Spindle speed *14 [min-1] | 12,000min-1 specifications : 1 - 12,000, 10,000min-1 high-torque specifications(Optional) : 1 - 10,000, 20,000min-1 specifications(Optional) : 1 - 20,000 |

||

| Speed during tapping [min-1] | MAX. 6,000 | |||

| Tapered hole | 7/24 tapered No.30 | |||

| BT dual contact system (BIG-PLUS) |

Optional | |||

| Coolant Through Spindle (CTS) | Optional | |||

| Feed rate | Rapid traverse rate (XYZ-axes) [m/min (inch/min)] |

50 x 50 x 56 (1,969 x 1,969 x 2,205) | ||

| Cutting feed rate [mm/min (inch/min)] |

X, Y, Z axis: 1 - 30,000 (0.04 - 1,181) *7 | |||

| Indexing feedrate (A and C) [min-1] | A axis: 50, C axis: 75 (60 *9) | |||

| ATC unit | Tool shank type | MAS-BT30 | ||

| Pull stud type*4 | MAS-P30T-2 | |||

| Tool storage capacity [pcs.] | 14 / 21 / 28 | 100 *12 | ||

| Max.tool length *1 [mm (inch)] | 250 (9.8) | |||

| Max.tool diameter *1 [mm (inch)] | 110 (4.3) | Turret magazine: 110 (4.3), Tool stocker: 60 (2.3) / 110 (4.3) (No adjacent tool) |

||

| Max.tool weight *1 [kg (lbs)] | 3.0 (6.6) [4.0 (8.8) *10] / tool, |

Turret magazine: 3.0 (6.6) [4.0 (8.8) *10] / tool,

Tool stocker: 4.0 (8.8) / tool, |

||

| Tool selection method | Random shortcut method | |||

| Tool change time *5 | Tool To Tool [sec.] | 0.6 / 0.7 (14 or 21 tools / 28 tools) | 0.7 *13 | |

| Chip To Chip [sec.] | 1.3 / 1.4 (14 or 21 tools / 28 tools) | 1.4 *13 | ||

| Electric motor | Main spindle motor (10 min/continuous)[kW] *2 |

12,000min-1 specifications: 10.1/7.0, 10,000min-1 high-torque specifications (optional):12.8/9.2, 20,000min-1 specifications(Optional) : 7.4/5.1 |

||

| Axis feed motor [kW] | XY axis: 1.0, Z axis: 2.0, A axis: 0.9, C axis: 0.55 | |||

| Power source | Power supply | AC 200 to 230 V±10%, 3-phase, 50/60Hz±2% | ||

| Power capacity (continuous) [kVA] | 12,000min-1 specifications : 9.5, 10,000min-1 high-torque specifications(Optional) : 10.4, 20,000min-1 specifications(Optional) : 9.5 |

|||

| Air supply | Regular air pressure [MPa] | 0.4 - 0.6(recommended value : 0.5MPa *6) | ||

| Required flow [L/min] | 52L/min | |||

| Machine dimensions | Height [mm (inch)] | 2,818 (110.9) | ||

| Required floor space*11 [with control unit door open] [mm (inch)] |

1,560 x 2,081 [2,919] (61.4 x 81.9 [114.9]) | 2,050 x 2,081 [2,919] (80.7 x 81.9 [114.9]) | ||

| Weight [kg (lbs)] | 2,650 (5,843) | 2,800 (6,173) | ||

| Accuracy*3 | Accuracy of bidirectional axis positioning (ISO230-2:1988) [mm (inch)] |

X, Y, Z axis: 0.006-0.020 (0.00024-0.00079) | ||

| (ISO230-2:2014) | A, C axis: 28 sec or less | |||

| Repeatability of bidirectional axis positioning (ISO230-2:2014) [mm (inch)] |

X, Y, Z axis: Less than 0.004 (0.00016) /A, C axis: 16 sec or less | |||

| Standard accessories | Instruction Manual (DVD 1 set), leveling bolts (4 pcs.), leveling plate (4 pcs.) |

|||

- *1 The maximum tool length, maximum diameter, and maximum weight are limited depending on the spindle speed in use, configuration, center of gravity, etc. The figures shown here are for reference only. Please contact your local distributor for details.

- *2 Spindle motor output differs depending on the spindle speed.

- *3 Measured in compliance with ISO standards and Brother standards. Please contact your local distributor for details.

- *4 Brother specifications apply to the pull studs for CTS.

- *5 Measured in compliance with JIS B6336-9 and MAS011-1987.

- *6 Regular air pressure varies depending on the machine specifications, machining program details, or use of peripheral equipment. Set the pressure higher than the recommend value.

- *7 When using high accuracy mode B.

- *8 The machine needs to be equipped with a relocation detection device depending on the destination. Machines equipped with a relocation detection device come with "RD" at the end of the model name.

- *9 When using high inertia mode. Parameter setting needs to be changed.

- *10 Parameter setting needs to be changed. (Tool indexing time is changed.)

- *11 The value does not include the coolant tank.

- *12 Value for turret magazine plus tool stocker

- *13 Value for turret magazine

- *14 The 16,000min-1 specification is discontinued as of March 2026.

| Item | U500Xd2 | U500Xd2-5AX | |

|---|---|---|---|

| CNC model | CNC-D00 | CNC-D00v (DB) | |

| Control axes | 5 axes (X, Y, Z, A, C) | ||

| Simultaneously controlled axes | Positioning | 5 axes (X, Y, Z, A, C) | |

| Interpolation |

Linear : 4 axes (X, Y, Z, 1 additional axis) Circular : 2 axes Helical/Conical : 3 axes (X, Y, Z) |

Linear: 5 axes (X, Y, Z, 2 additional axes) Circular: 2 axes Helical/Conical: 4 axes (3 linear axes + 1 additional axis, 2 linear axes + 2 additional axes) |

|

| Least input increment | 0.001mm, 0.0001inch, 0.001 deg. 0.0001mm, 0.00001inch, 0.0001 deg. (optional) |

0.0001 mm, 0.00001 inch, 0.0001 deg. | |

| Max.programmable dimension | ±999999.999mm, ±99999.9999inch ±999999.9999mm, ±99999.99999inch (optional) |

±999999.9999 mm, ±99999.99999 inch | |

| Display | 15-inch color LCD touch display | ||

| Memory capacity | 500 Mbytes, 3 Gbytes (optional) (Total capacity of program and data bank) |

3 Gbytes (Total capacity of program and data bank) |

|

| External communication | USB memory interface, Ethernet, RS232C (optional) | ||

| No.of registrable programs | 4,000 (Total capacity of program and data bank) | ||

| Program format | NC language, conversation (changed by parameter) Conversation from conversation program to NC language program available * Only NC language available on the U500Xd2-100T. Conversation language not available |

NC language * Conversation language not available |

|

- * "Control axes" and "Simultaneously controlled axes" indicate the maximum number of axes, which will differ depending on the destination country and the machine specifications.

- * Ethernet is a trademark or registered trademark of XEROX in the United States.

| Operation | Dry run Machine lock Program restart Rapid traverse override Cutting feed override Background editing Screen shot Operation level External input signal key Shortcut keys < optional > |

|

|---|---|---|

| Programming | Absolute / Incremental Inch / Metric Coordinate system setting Corner C / Corner R Rotational transformation Synchronized tap Subprogram Graphic display |

|

| Measurement | Automatic workpiece measurement *1 Tool length measurement |

|

| High speed and high accuracy | Machining parameter adjustment High-accuracy mode AIII High-accuracy mode BI (look-ahead 160 blocks) Backlash compensation Tool center point control *3 (Look-ahead 1,000 blocks) < optional > |

|

| Monitoring | Machining load monitoring ATC monitoring Overload prediction Waveform display / Waveform output to memory card Heat expansion compensation system ll (X, Y, and Z axes) Production performance display Tool life / Spare tool Chip detection function |

|

| Maintenance | Tap return function Status log Alarm log Operation log Maintenance notice Motor insulation resistance measurement Tool washing filter with filter clogging detection Battery-free encoder Breake load test |

|

| Automatic / Network | Computer remote OPC UA Auto notification Built-in PLC (LD/ST/FBD) < optional > |

|

| Energy saving | Automatic power off Standby mode Automatic coolant off Automatic work light off Chip shower off delay Chip shower energy savings operation Energy savings mode |

|

| Support apps | Adjust machine parameters ATC tool Tool life Waveform display Production performance Energy saving/Power consumption Recovery support Inspection PLC Machining support without warmup Software control panel |

|

| Accessories | File viewer Notebook Calculator Register shortcut Display off |

|

| Functions limited to NC language | Menu programming Local coordinate system Expanded workpiece coordinate system One-way positioning Inverse time feed Programmable data input Tool length compensation Cutter compensation Scaling Mirror image External sub program call Macro Tape operation / FTP load operation Multiple skip function < optional >

|

|

| Functions limited to conversation language *5 | Operation program Schedule program Automatic tool selection Automatic cutting condition setting Automatic tool length compensation setting Automatic cutter compensation setting Automatic calculation of unknown number input Machining order control |

|

- *1 For the measuring instrument, please select an optional touch probe or provide one yourself.

- *2 When the submicron command is used, changing to the conversation program is disabled.

- *3 Available only for the U500Xd2-5AX.

- *4 Standard on the U500Xd2-5AX.

- *5 Conversation language not available on U500Xd2-5AX and U500Xd2-100T.

Example