- Products

- Support & Download

- Solutions

- Contacts

- About Brother

SPEEDIO

M140X2 Features

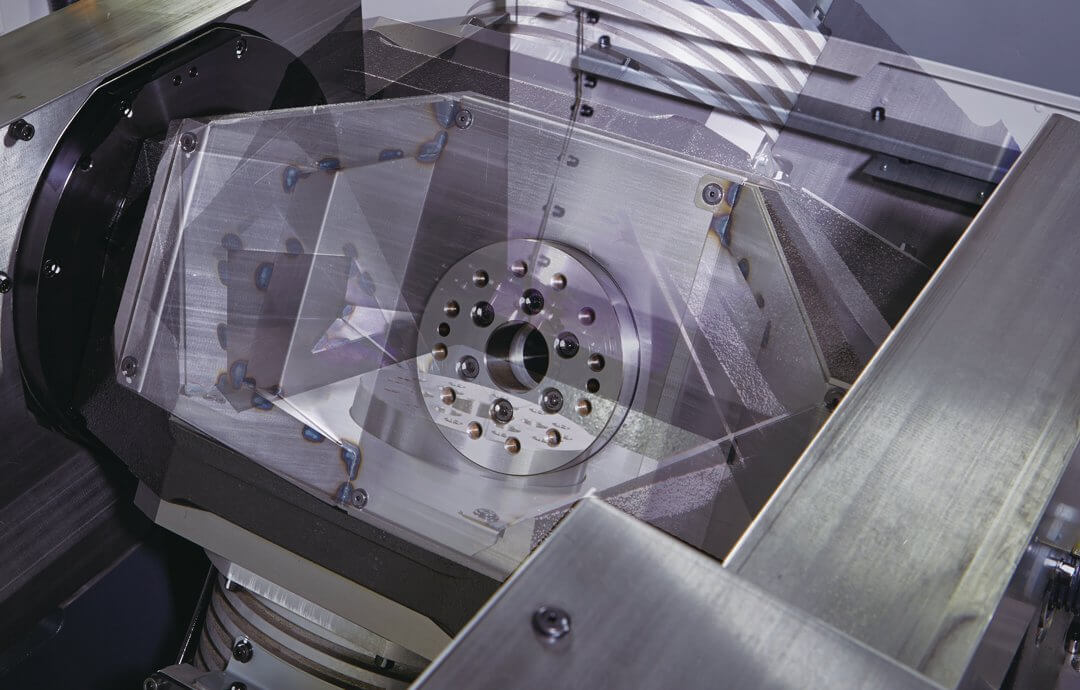

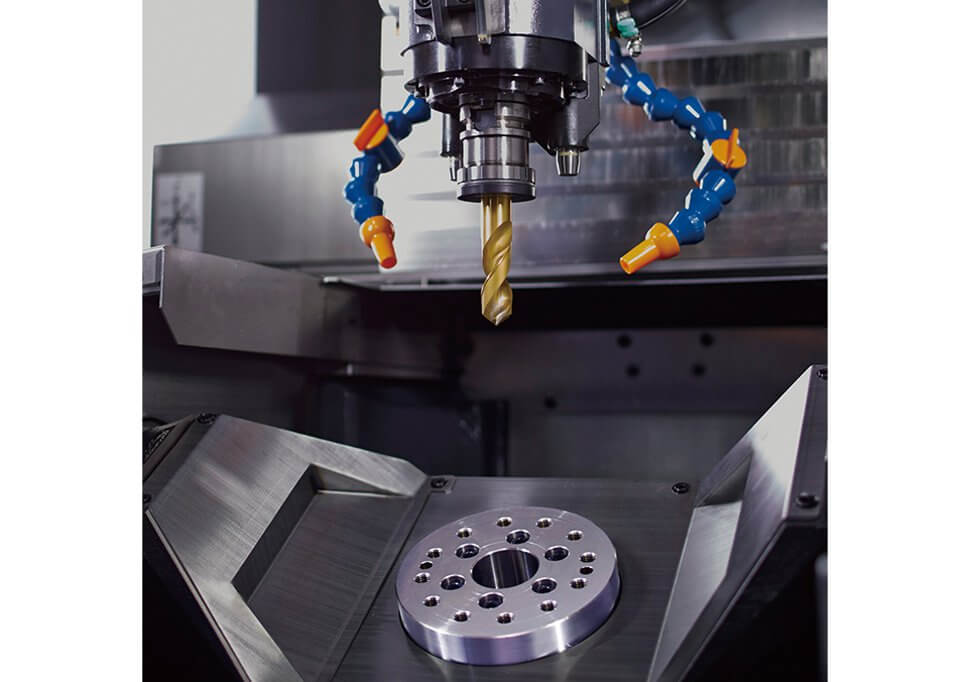

The compact multi-tasking machines, equipped with turning and tilt axes, enable turning and machining processes through one-time chucking. It also achieves high productivity, cultivated up to now, in the complex machining field.

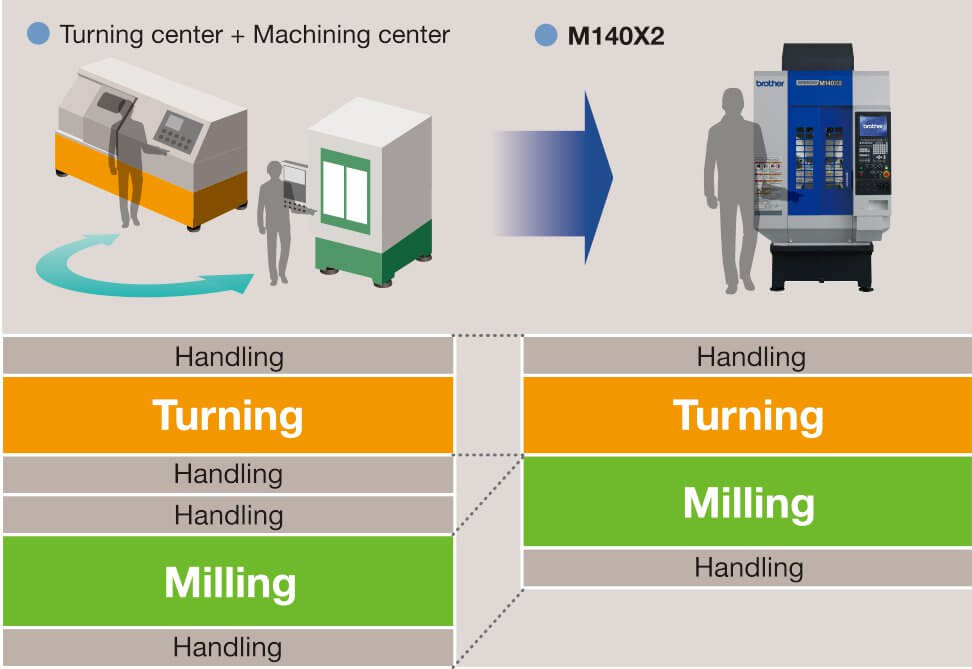

Effects of Mass Production Type Complex Machining

Process integration in one machine

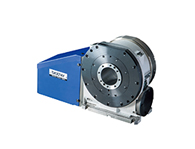

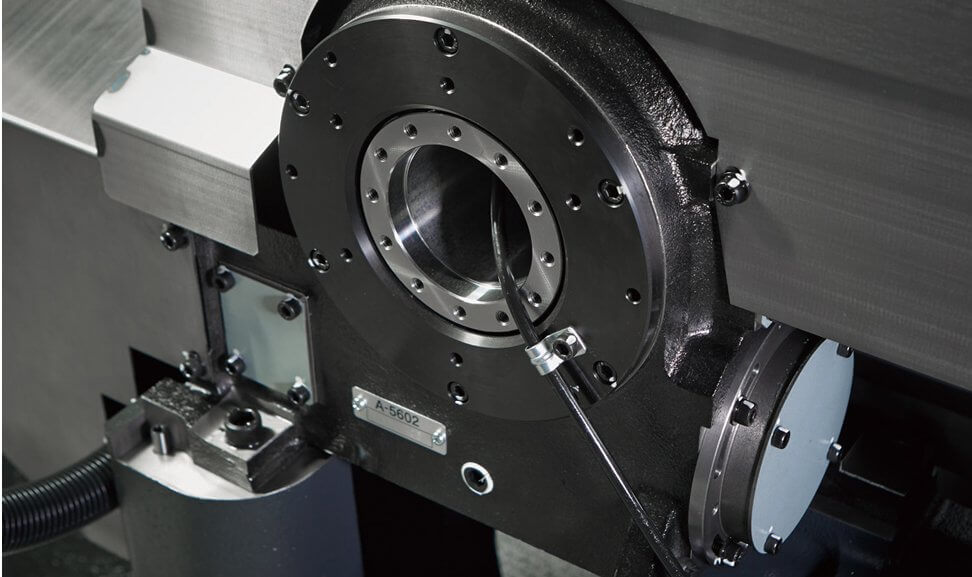

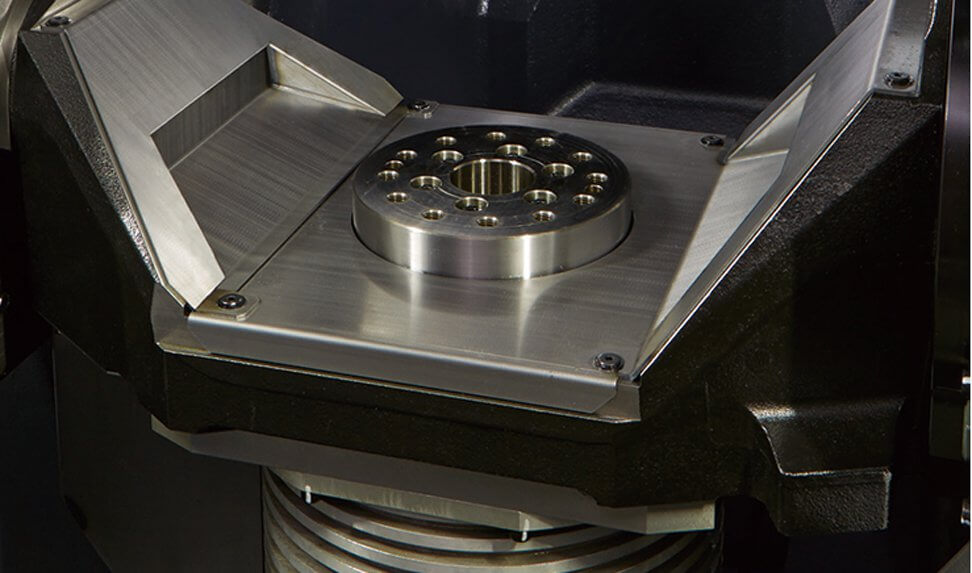

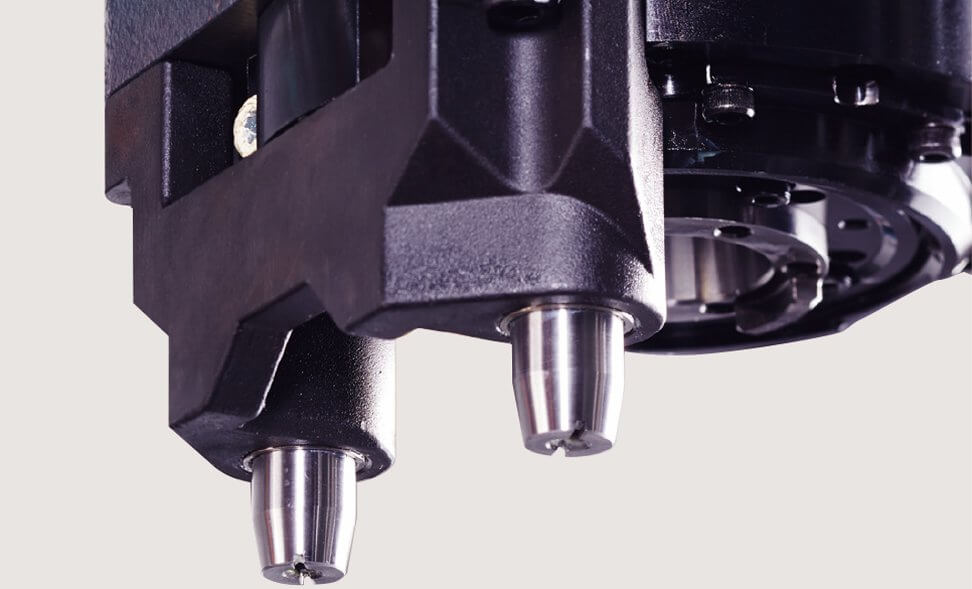

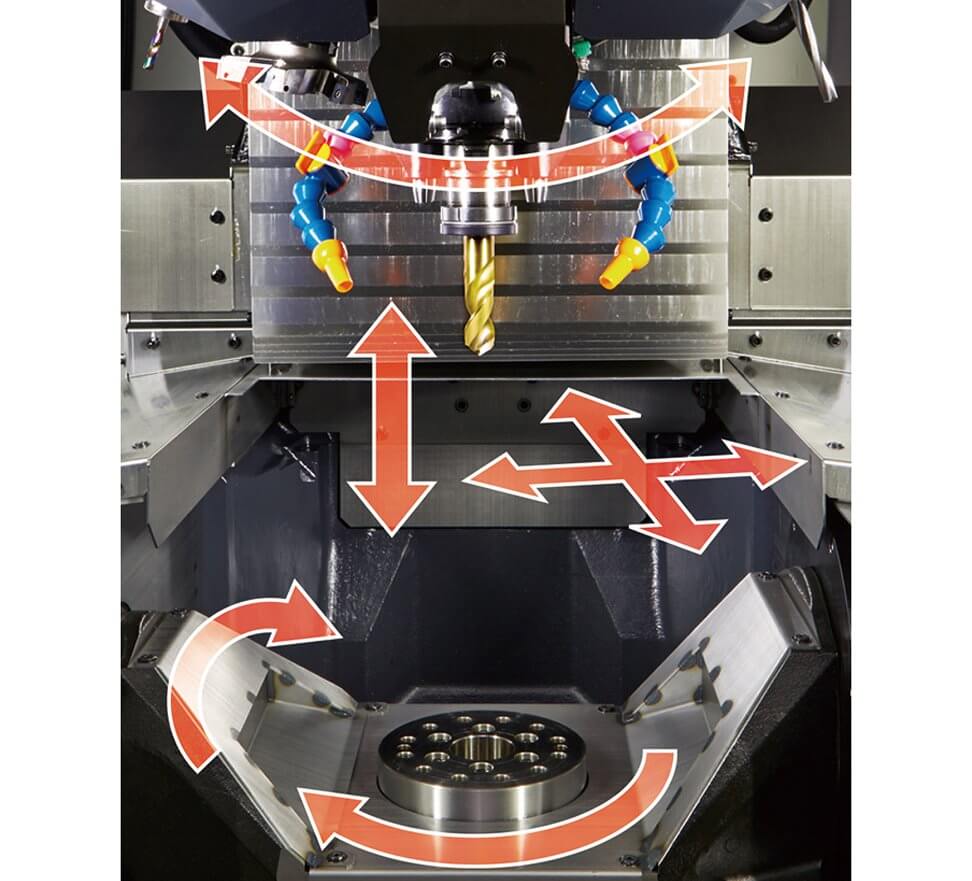

Machine Structure that Achieves Complex Machining

Machining capabilities and accuracy have been improved by increasing the rigidity of the tilt axis and turning spindle, and improving the balance of rigidity over the previous model. A double plunger lock, with a reputation for stable machining, is used to secure the turning tool.

Tilt axis (A-axis)

Turning spindle (C-axis)

Double plunger lock

Productivity

Fast acceleration / deceleration spindle

High-speed tool change

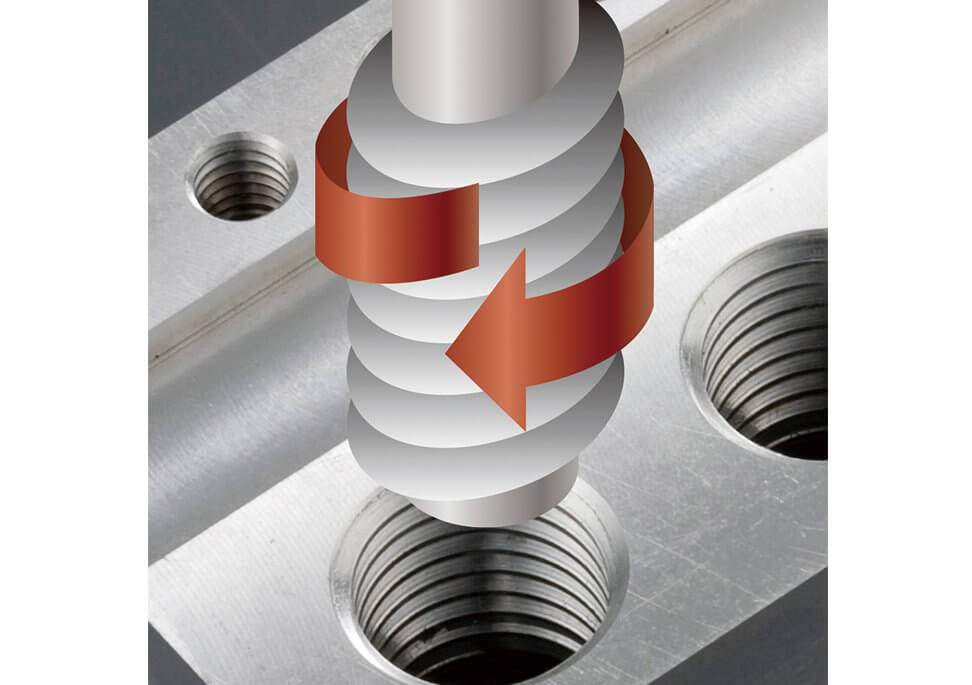

High-speed synchronized tapping

Simultaneous operation

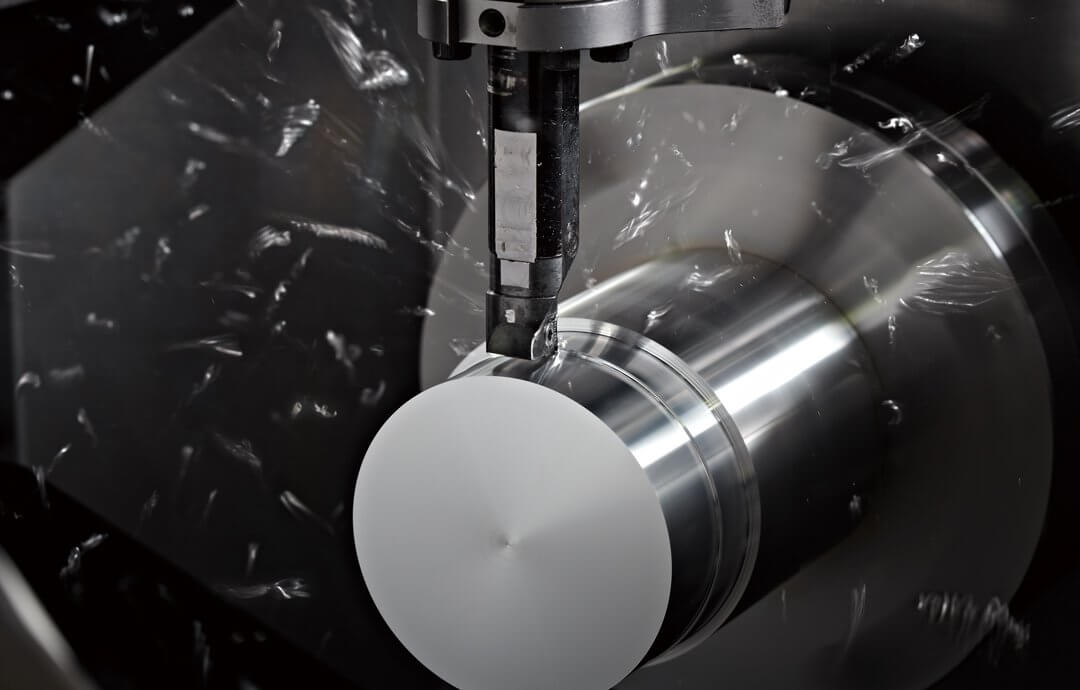

Machining Capabilities

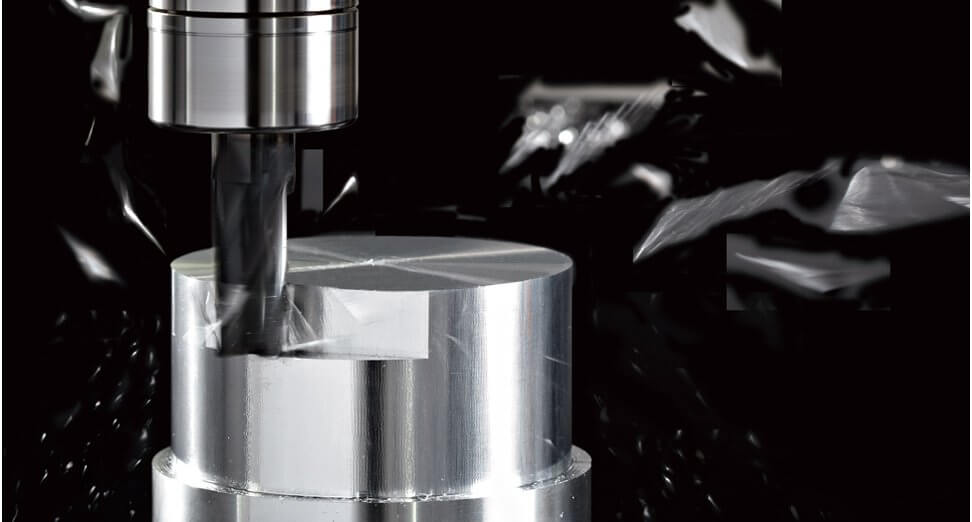

Milling capabilities

Turning capabilities

Environmental Performance and NC Unit

Environmental performance

NC unit

Customer considering purchase / Support Information

-

Catalog download

Guide of Compact machining center SPEEDIO catalog download.

-

Distributors - Inquiry & Purchase , Repair & Service

Contact information for distributors in your area.

-

Brother Technology Center

Contact information for Brother Technical Centers in Europe and other areas.